Jodoo Maintenance Management Solution

Unify asset records, work orders, preventive maintenance, inspection, and inventory. Computerize every step of equipment, asset, and maintenance management in one system. Standardize execution, surface KPIs instantly, and scale without rework.

Trusted by businesses worldwide

Highlights of our Solution

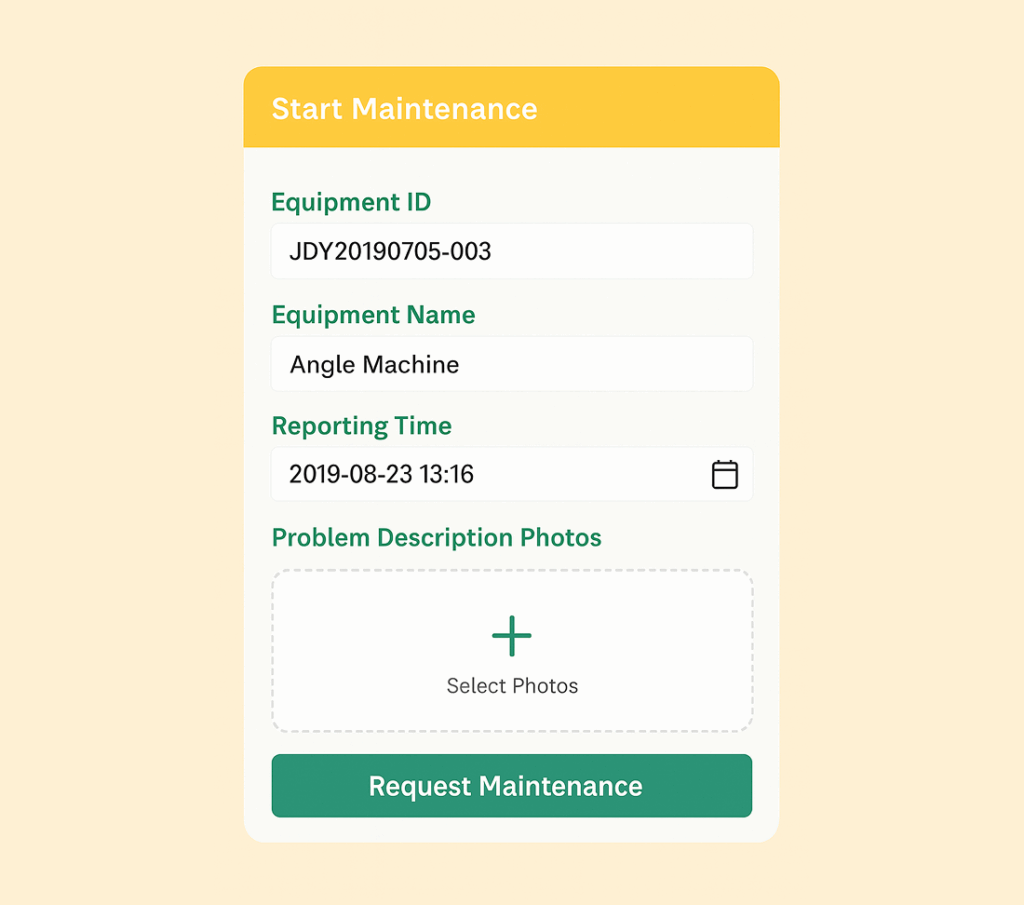

Submit a repair in 3 seconds to cut MTTR

- Start a corrective maintenance work orders by scanning the equipment tag and attaching photos, text, or short videos.

- Notify the right technician instantly and track response, travel, and fix times automatically.

- Shorten the fault lifetime by removing back-and-forth and making context visible at the first touch.

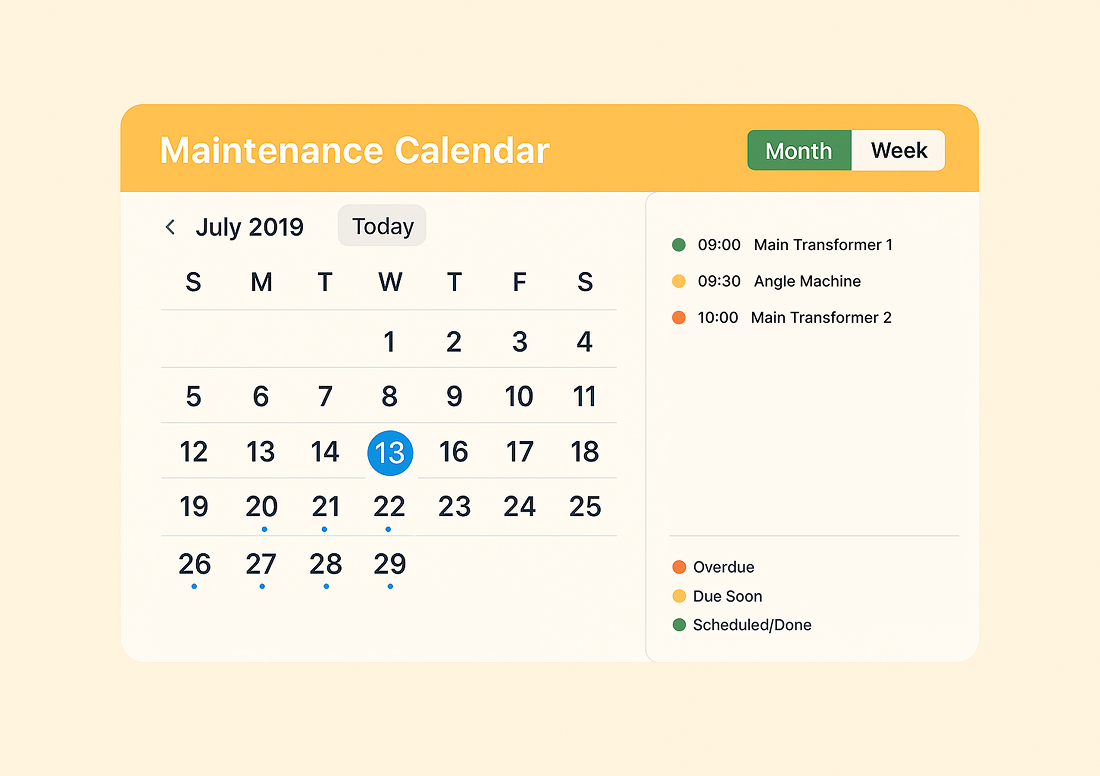

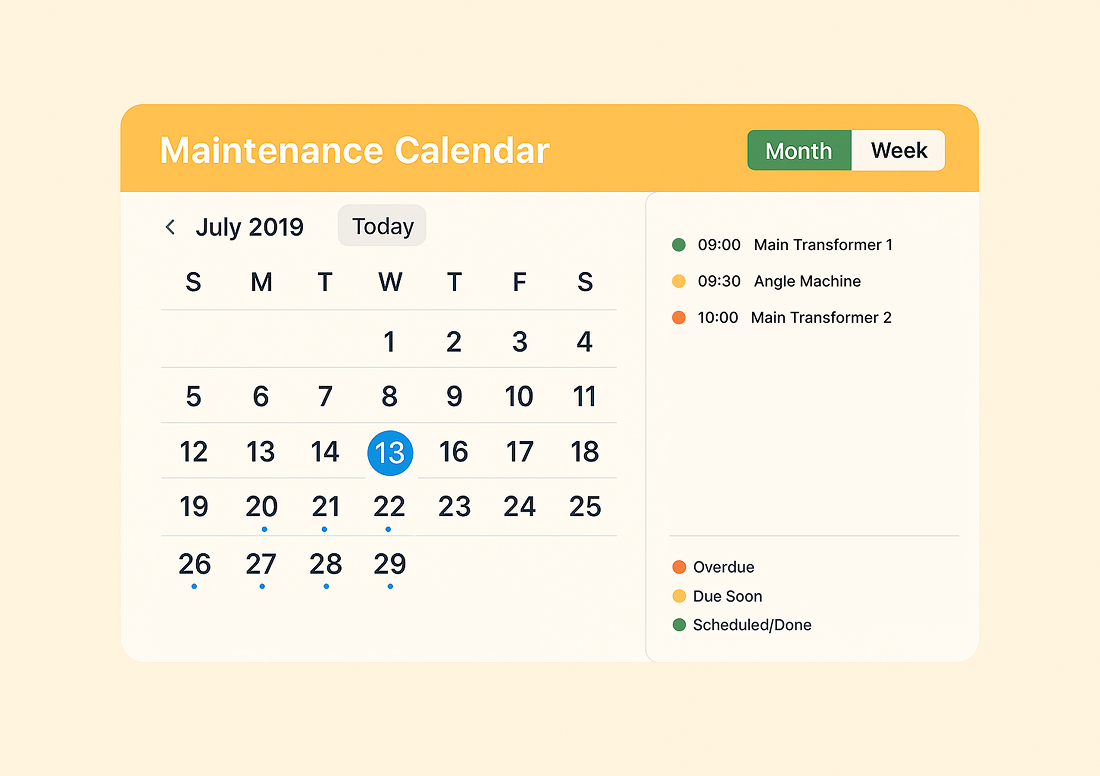

Plan maintenance on a calendar everyone understands

- Generate preventive maintenance and periodical service tasks by date, runtime, or usage rules and visualize them on a shared calendar.

- Send reminders to the assignee at the right time and escalate when tasks slip.

- Align with production schedules and avoid avoidable collisions between PM and throughput.

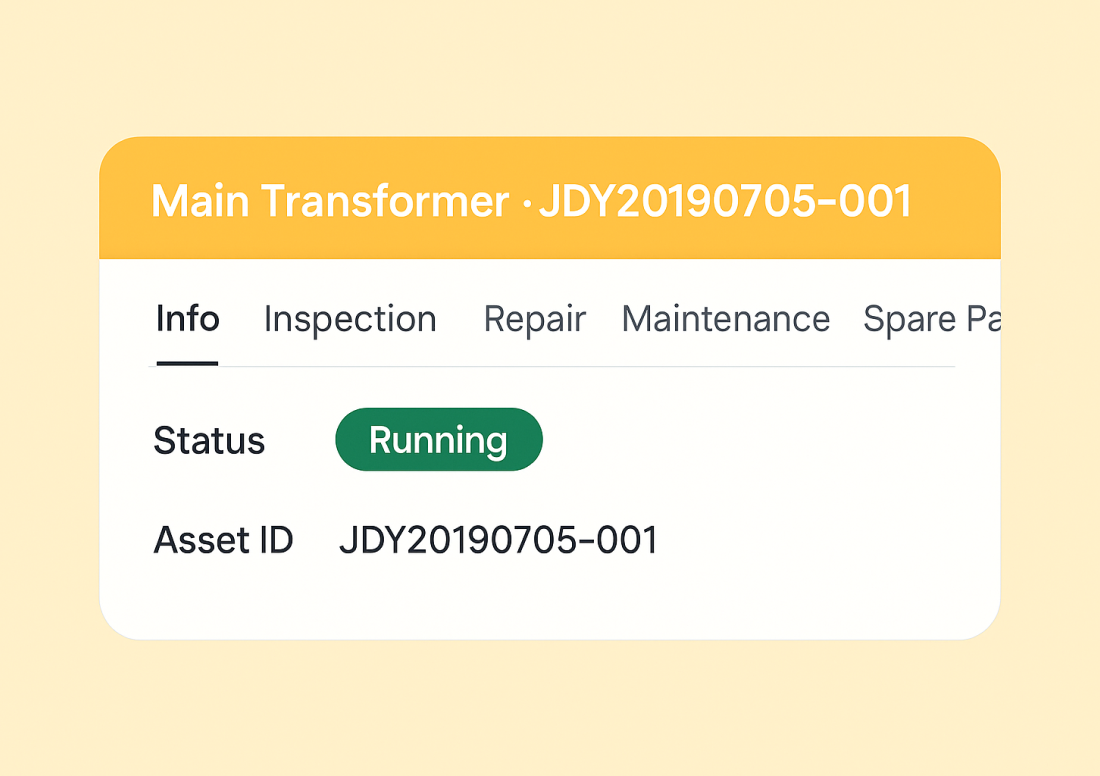

Link static files and dynamic history in one place

- Centralize manuals, photos, and nameplate data with every inspection, repair, and parts change.

- Maintain a single source of truth that updates in real time as forms are submitted.

- Scale fields and relationships with no-code so the model grows with your operations.

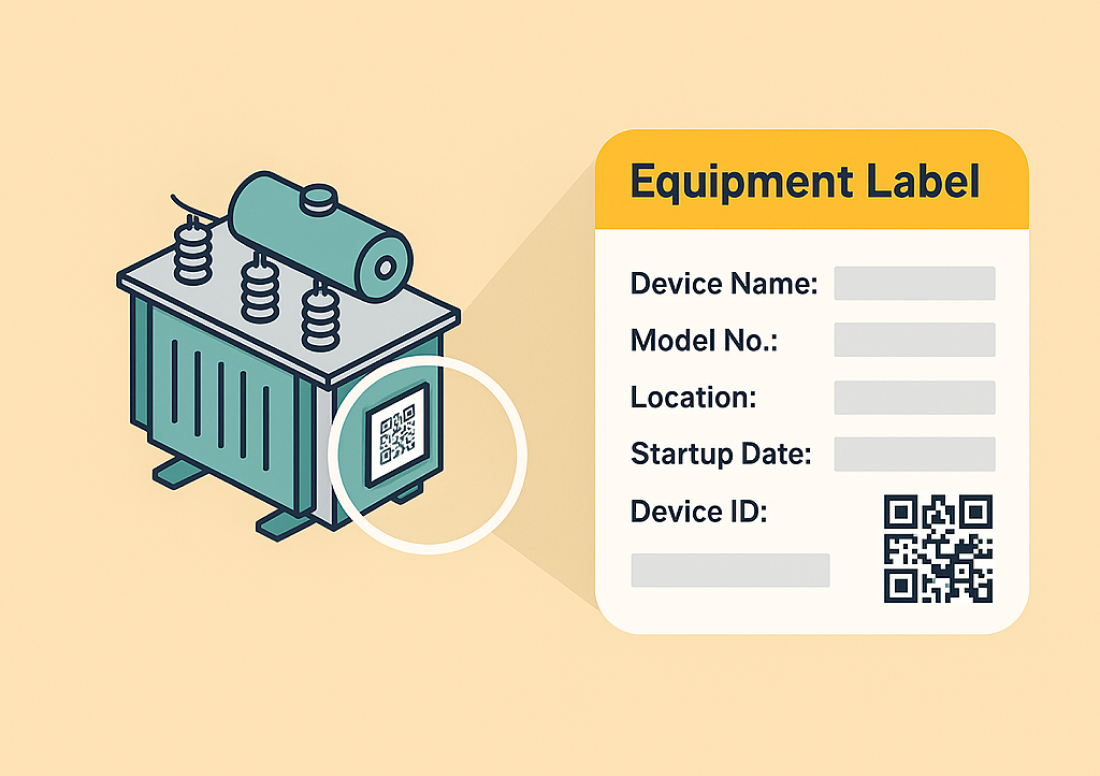

Scan one code, run every workflow

- Activate equipment records by scanning a unique QR on each asset.

- Open work orders, start inspections, view history, and check KPIs directly from the shop floor.

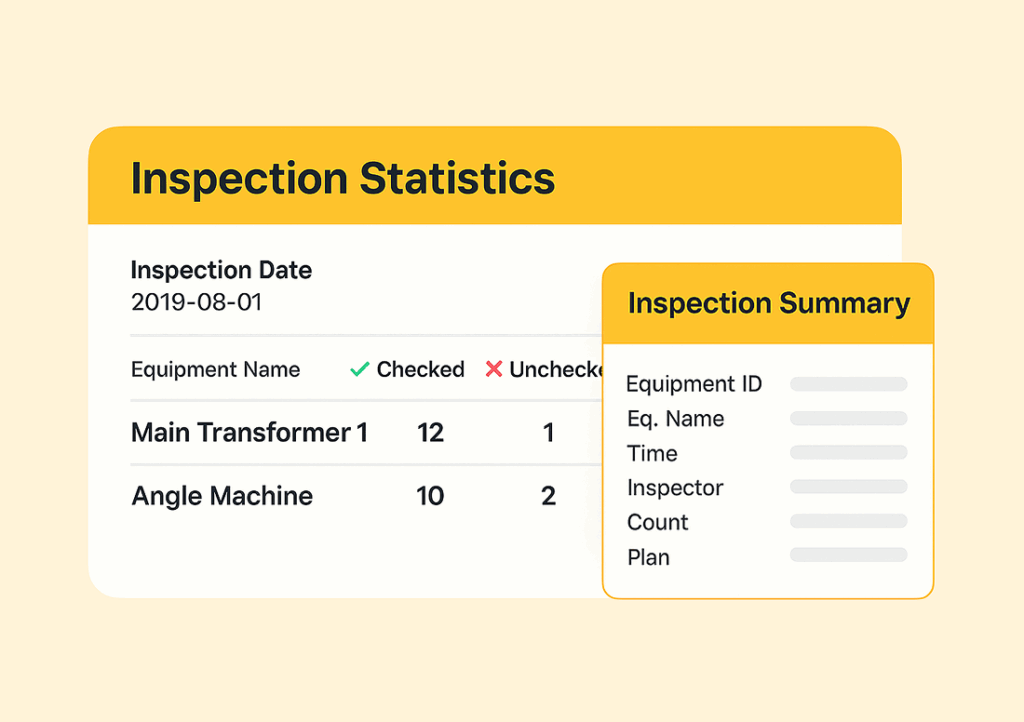

Digitize inspections and show “done vs. due” in real time

- Standardize checklists, set cycles, and push mobile reminders so nobody forgets a route.

- Verify on-site execution with QR scans, timestamps, GPS, and required photos.

- Surface completed vs. pending inspections on dashboards so maintenance supervisors close gaps fast.

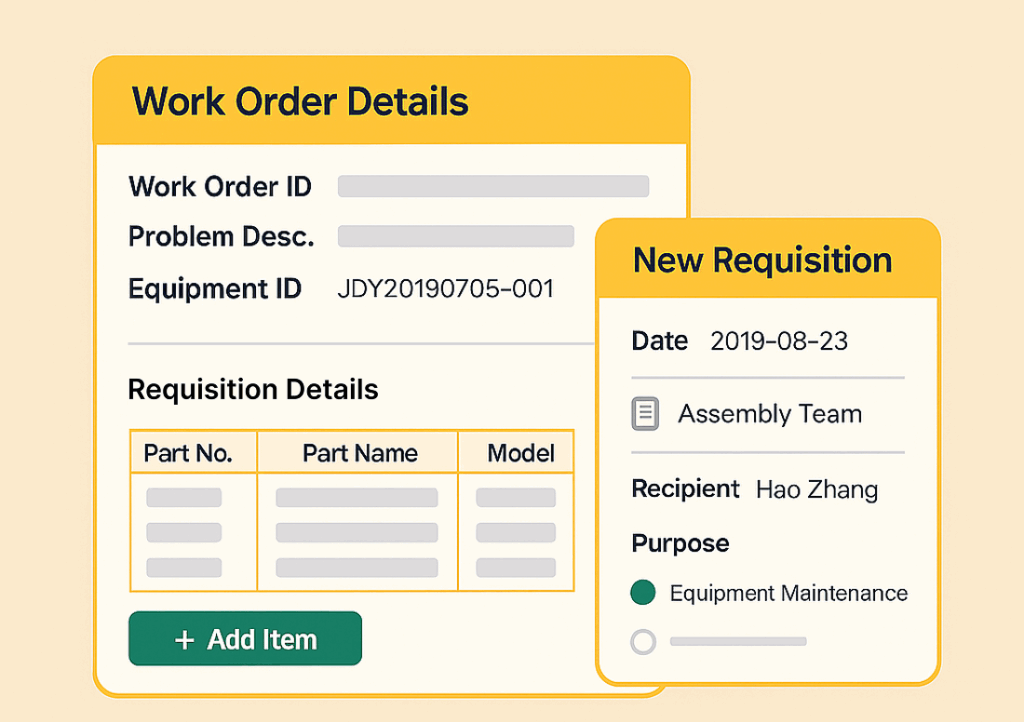

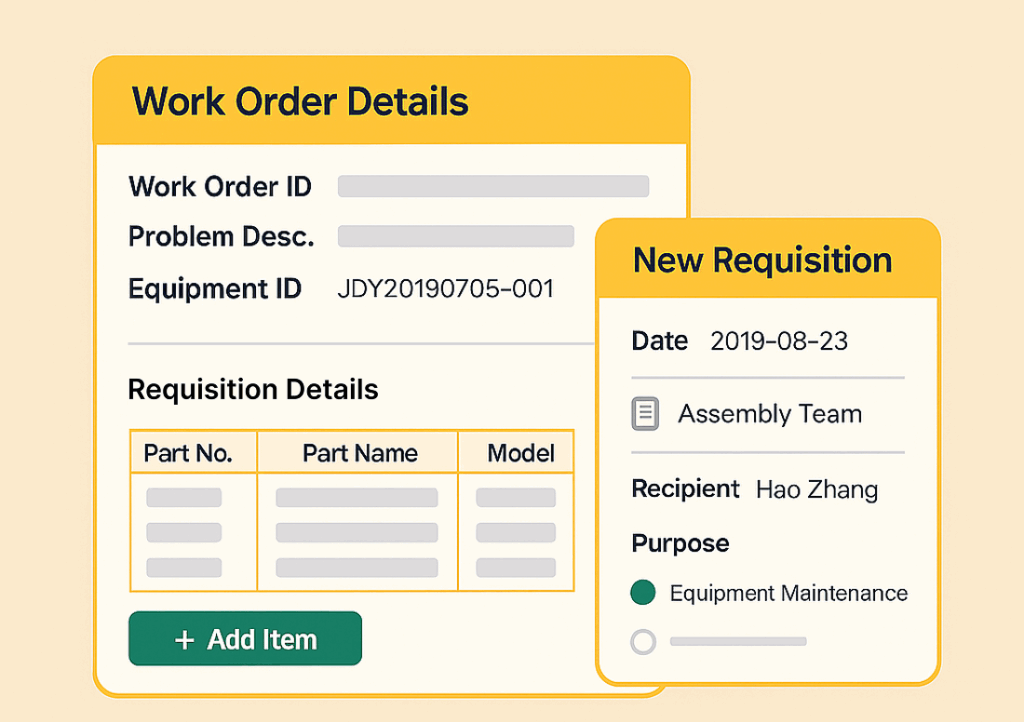

Track spare parts from bin to job with full traceability

- View on-hand balances in real time and set par levels for each location.

- Record who picked what and when, then link issuances to the originating work order.

- Trigger low-stock alerts before stockouts and roll parts costs into asset and line KPIs automatically.

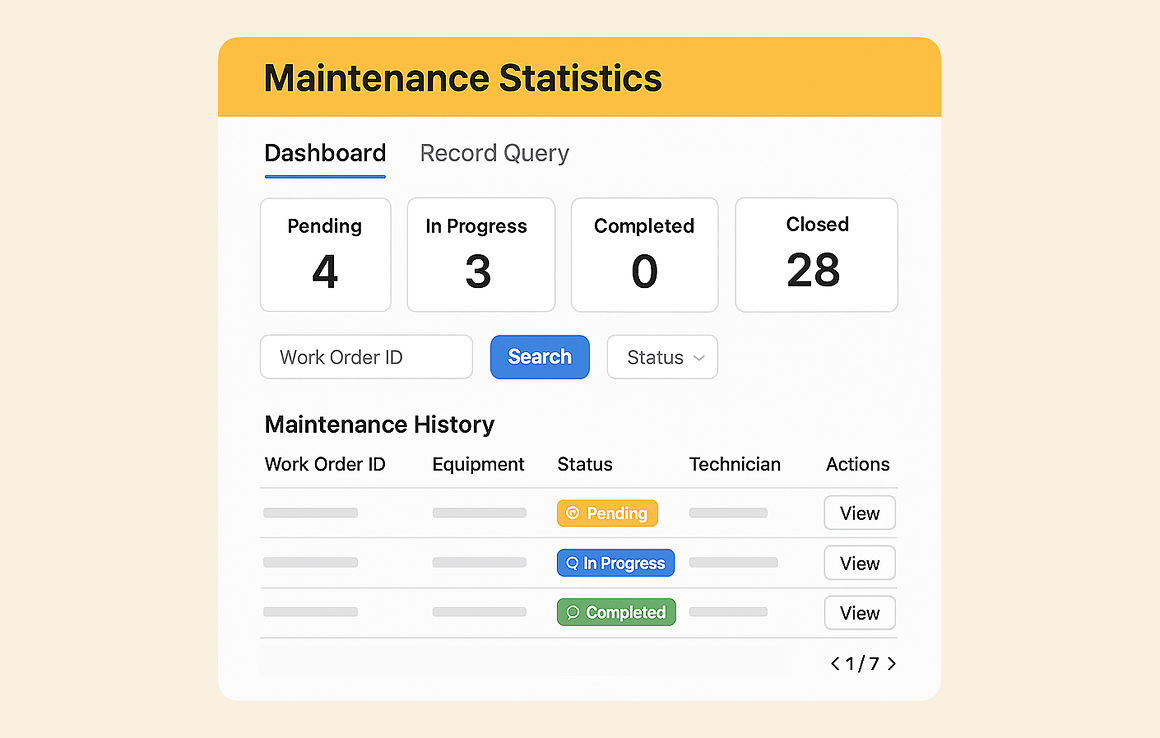

Analyze performance from every angle

- Open mobile and desktop dashboards to review downtime, MTTR, PM compliance, and parts consumption by plant, line, shift, or asset class.

- Filter and drill into outliers to decide the next best action.

- Create custom metrics and visuals with no-code to reflect how your operation actually runs.

Ensure compliance

Support supervisors and managers with role/site/asset permissions. Record all actions as auditable events for compliance.

Track technician time accurately

Start and stop job timers on mobile, roll labor into cost per asset, and show maintenance supervisors where time is going.

Support 12+ languages

Support Bahasa Indonesia, Vietnamese, and Thai interfaces and forms, so mixed crews can work without barriers.

Launch fast with QR labels and Excel

Import master data from Excel, batch print QR labels, stick them on assets, and start routes within weeks.

Measure what supervisors care about

Track MTTR, PM compliance, downtime minutes, stockout rate, and unit maintenance cost.

Enforce SLAs and escalations

Set timers for response and fix times, notify the next supervisor when limits are exceeded, and cut MTTR on corrective maintenance.

Why Jodoo

Deploy instantly with ready-made templates

Launch systems using a wide selection of out-of-the-box templates for industry-tailored workflows. Every template is fully customizable to fit your unique business needs.

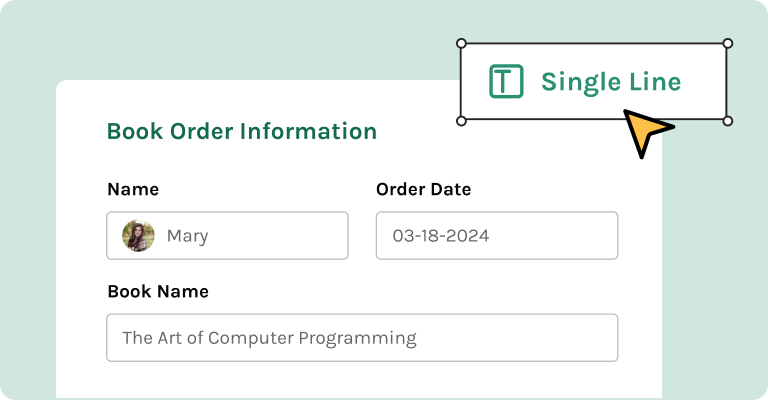

Build custom apps with intuitive drag-and-drop builders

Create and adapt forms, automations, and dashboards visually, without any coding required.

Manage work the way you prefer across any device

Switch between Gantt, Kanban, and grid views to match your workflow. Access and update your data on desktop, tablet, or mobile in 12 + languages your crews actually speak.

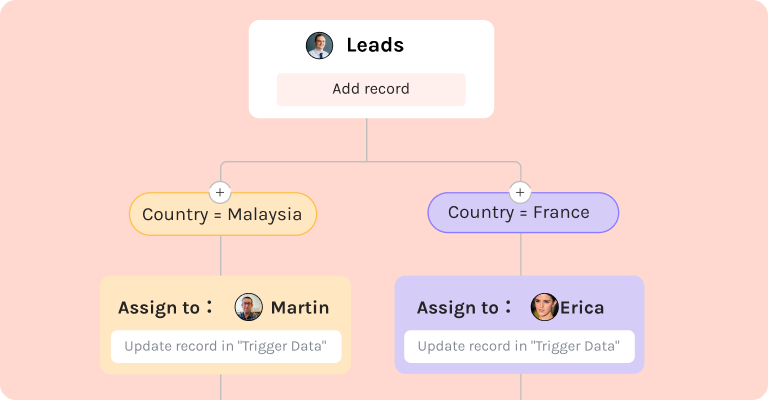

Automate routine processes and approvals

Set up automation rules for approvals, notifications, and reminders. Streamline repetitive processes so your team can focus on what matters most.

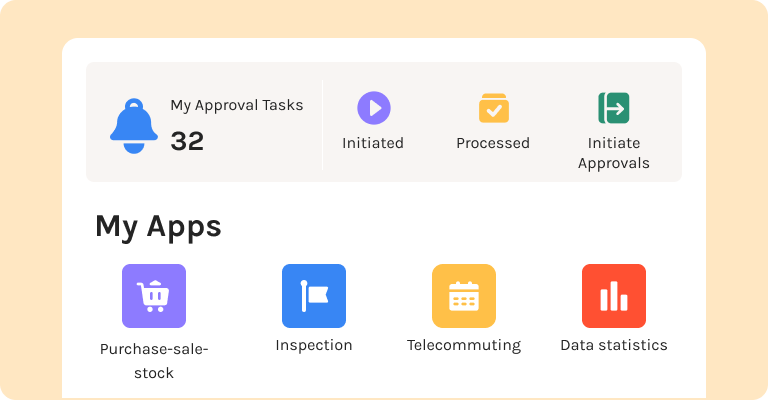

Automate your contract and site approvals

Link every workflow—HR, finance, operations, CRM—on a single platform. Ensure real-time insights with synchronized, easily accessible data.

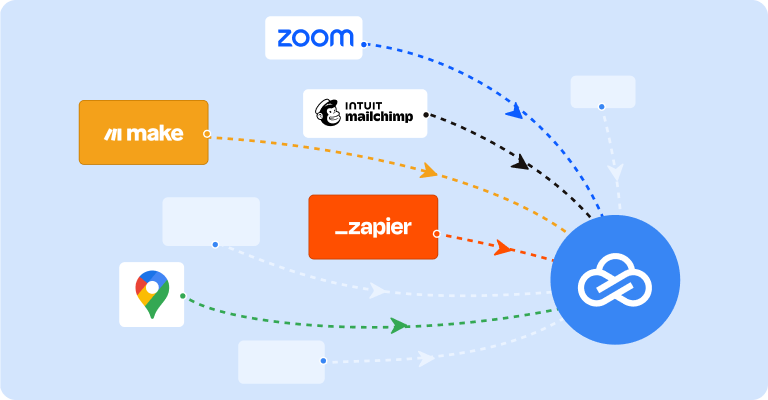

Integrate and scale as your business grows

Connect easily with third-party tools and systems. Expand to support more users, apps, and data without limits on capacity or performance.

Your security is our top priority

Ready to cut downtime and MTTR, and hit every PM on schedule?

FAQs

Install the free CMMS template, scan your first QR, and import assets with an Excel file. Book a free guided demo if you want a tailored tour.

Paper logs, spreadsheets, and chat groups cannot track downtime, PM compliance, or spare parts accurately. A CMMS standardizes work orders, inspections, preventive maintenance, and inventory on one system. Jodoo goes further by combining CMMS strength with a no-code platform: you start with ready-made templates, customize without coding, and expand into HR, finance, or operations when needed. This lowers total cost of purchasing multiple systems and makes adoption faster than traditional software.

Export existing lists, map columns to the template, and bulk-create assets with unique IDs. Replace paper with mobile forms and keep a read-only archive for reference.

Open the builder, drag fields into the form, and set rules for priorities, approvals, and notifications. Choose calendar, runtime, or usage triggers to generate PM tasks.

Track MTTR, downtime, PM compliance, and stockout rate on dashboards. Compare baseline vs. post-go-live periods and export charts into monthly reviews.

Replace rigid, IT-led change in on-prem tools and the fixed templates of other SaaS by making no-code updates in minutes. Run work orders, inspections, preventive schedules, spare parts, purchasing, and light finance on one platform instead of a stack of independent apps. Drive adoption with QR-triggered flows and interfaces. Trace asset → corrective maintenance → parts issuance → cost roll-up in a single auditable trail and focus supervisors on cause and impact, not tickets. Cut time-to-value and total cost, and onboard data quickly with Excel import and export.

Create a parts catalog, record receipts and issues, and link picks to work orders. Roll parts and labor into asset costs and monitor thresholds with alerts.

Apply encryption in transit and at rest, restrict access with roles, and retain audit logs. Align with GDPR requirements and support SOC 2 and ISO 27001 best-practice controls.

Choose KPIs, add filters for plant, line, and shift, and publish role-specific views. Share links or display boards on TVs to drive daily stand-ups.

Connect via Excel imports and exports to start fast. Consolidate daily operations on Jodoo by managing work orders, purchasing, inventory, payroll, and reimbursements on the same platform. Keep financial accounting in your ERP if preferred and sync reference data and documents later with APIs.

Import Excel files for assets, parts, vendors, and users. Map columns in the wizard, validate results, and publish in minutes. Export updated records to Excel anytime for audits and reviews.

Jodoo supports Bahasa Indonesia, Japanese, German, and other languages. Switch UI and forms to supported languages and localize field labels, so operators see the app in their own language.

Assign roles for operators, techs, planners, and managers. Limit access by site, line, or asset class and require approvals for sensitive actions.

Require QR scans at the asset, capture GPS and timestamps, and enforce photo evidence on critical points. Show due vs. done lists so supervisors intervene early.

Extend the same platform to EHS checks, calibration, quality, or energy rounds. Add apps with no-code and keep all data unified on one source of truth.