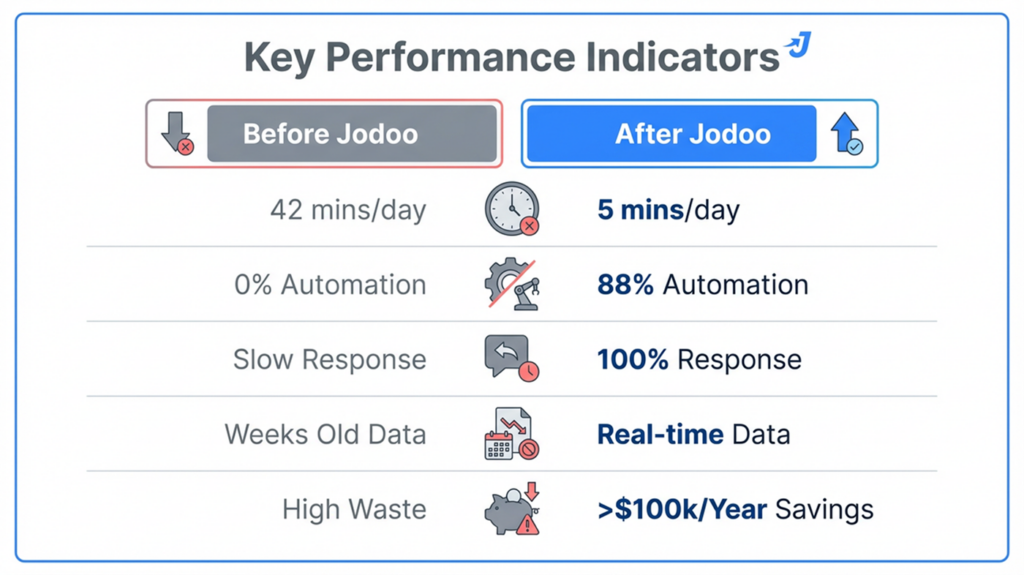

88.1%

Process Automation Rate

100%

Issue Reply Rate

41%

Reduction in Decision-Making Time

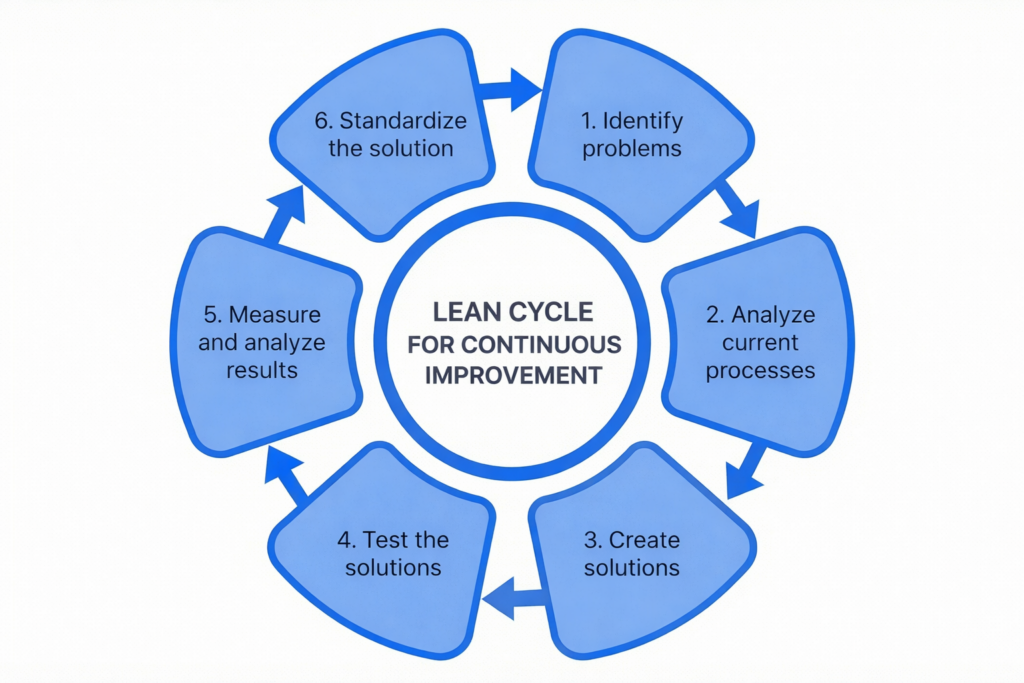

Cimtas Ningbo Steel Processing Co., Ltd. (Cimtas Ningbo), a wholly owned subsidiary of Cimtas Group – one of Turkey’s leading industrial contractors – specializes in complex piping systems and modular equipment for power plants, oil & gas facilities, and chemical plants. Safety is the top priority, and product quality is the company’s hallmark.They are known for world-class products, on-time delivery, and a commitment to continuous improvement using lean manufacturing principles.

But even the best processes can get stuck in old systems. Cimtas had a strong commitment to Lean—the Japanese philosophy of continuous improvement—but their tools were holding them back. The answer came not from a big IT project, but from a small team in the Quality Department who decided to take matters into their own hands.

The Challenge: When Good Processes Are Trapped in Old Systems

Cimtas is a company obsessed with quality. They live by the principle of Lean, or continuous improvement. For them, this means finding and fixing problems fast. But their old way of doing things was holding them back.

They had a strong process on paper, but in practice, it was slow and clumsy. While Cimtas relied on robust, industry-standard systems—namely Oracle’s JDE ERP for core business processes and Microsoft SharePoint for collaboration—these systems failed to address the “last mile” of continuous improvement on the shop floor.

The existing process for managing these problems was slow, opaque, and highly inefficient, creating three major roadblocks to continuous improvement:

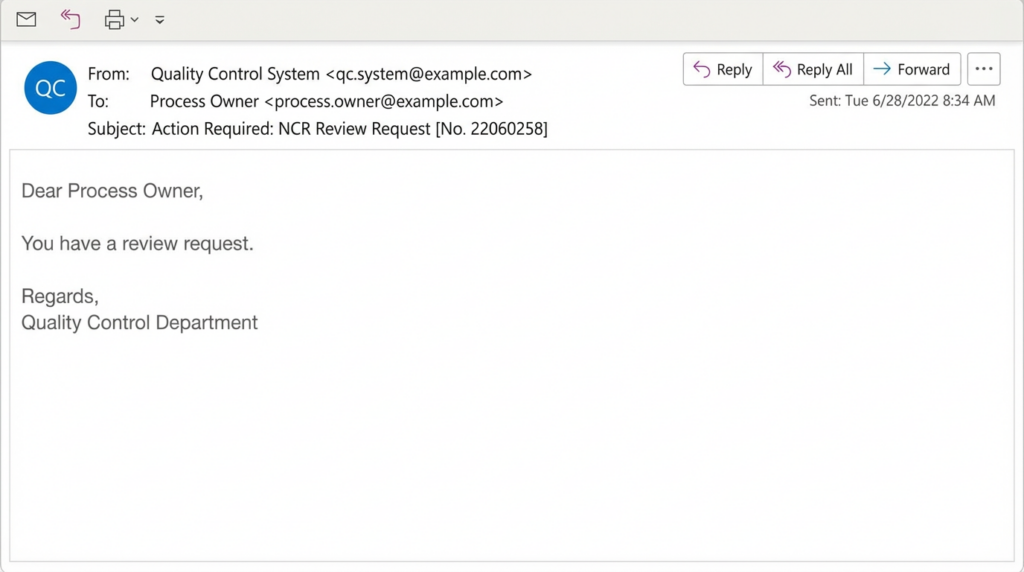

- Slow and Unclear Problem Reporting: When a problem happened on the factory floor, getting the word out was a struggle. The right people didn’t get the information they needed right away. The ERP system would send an email, but it was just a bit of text. It didn’t include pictures, which are very important in manufacturing. Other managers and team soften waited a week or more for someone to consolidate data into a spreadsheet or slide deck.By then, it was old news.

- Poor Communication and Follow-Up: Finding a problem is only the first step. Fixing it requires teamwork and clear communication. But Cimtas’s old system made this difficult. Replying to an issue meant logging into the ERP system on a desktop computer. There was no easy way to track the conversation or see if progress was being made. This lack of transparency meant that some problems were ignored or forgotten, and it was hard to tell who was actively working on a solution and who was not.

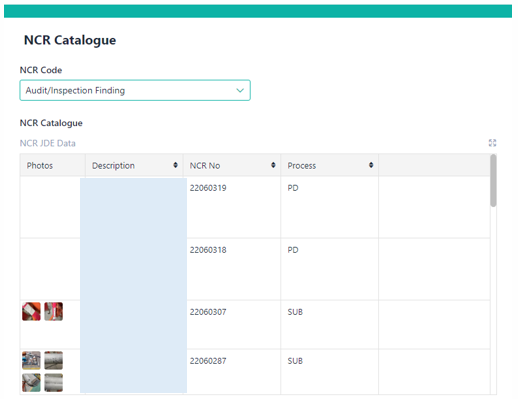

- Wasted Data and Repeated Mistakes: In manufacturing, history often repeats itself. The same problems can pop up again and again. Cimtas knew they had a lot of valuable data about past issues, but it was locked away in old reports and emails. There was no easy way to search for similar problems from the past to see how they were solved. This meant that teams were often reinventing the wheel, and the company was not learning from its own experience. It was a missed opportunity to spot trends and prevent future problems before they happened.

Cimtas needed a better way. They needed a tool that was fast, visual, and easy to use for everyone, from the factory floor to the management office. They needed to bring their commitment to continuous improvement into the digital age.

The Solution: Business-Led Innovation with a No-Code Platform

Cimtas didn’t want another complex, top-down IT project. They wanted a solution that the business team could build and manage themselves. The answer came from Li Shan, the head of the Quality Department. He discovered Jodoo, a no-code platform that lets people without programming skills build powerful applications.

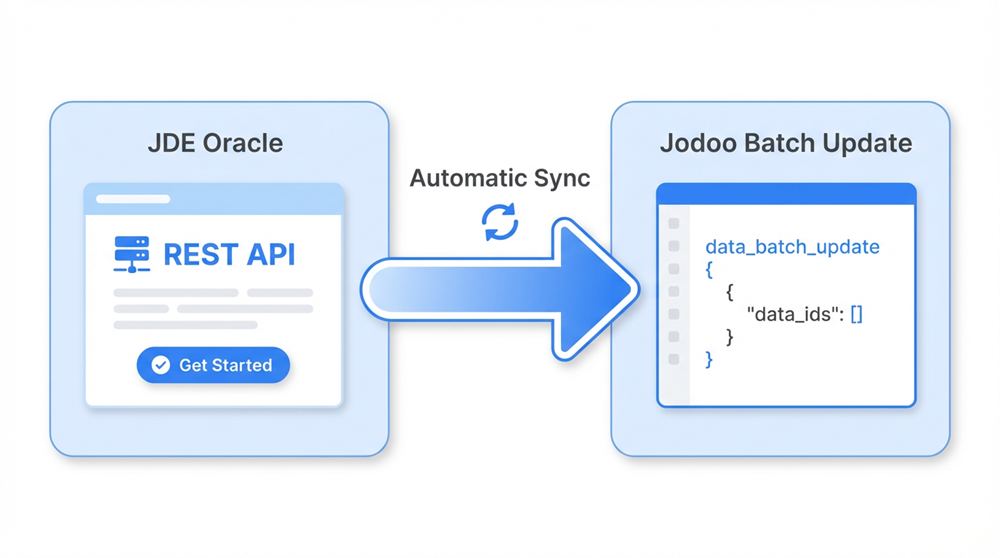

Instead of waiting for IT, Li Shan’s team became the developers. They knew the problems better than anyone, and with Jodoo, they had the power to build the exact solution they needed. They didn’t replace their powerful Oracle ERP; they built a bridge to it. In a short time, they created a simple, smart system that solved their biggest challenges.

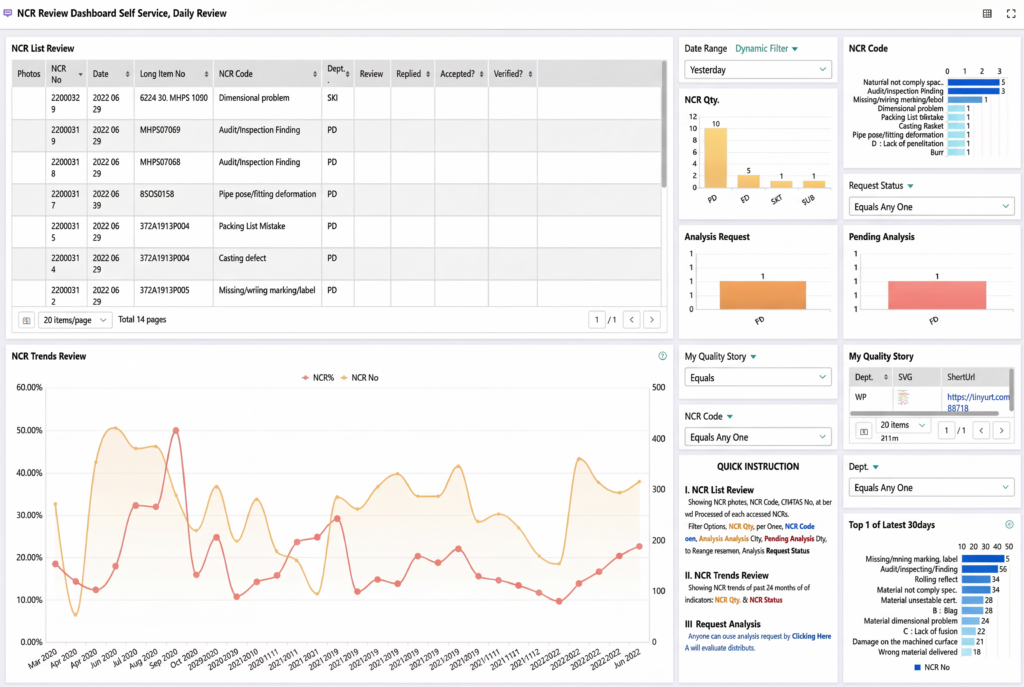

A Clear, Real-Time View of Every Problem

First, the team tackled the problem of slow and unclear reporting. They used Jodoo to create a central place for all quality issues. Here’s how it worked:

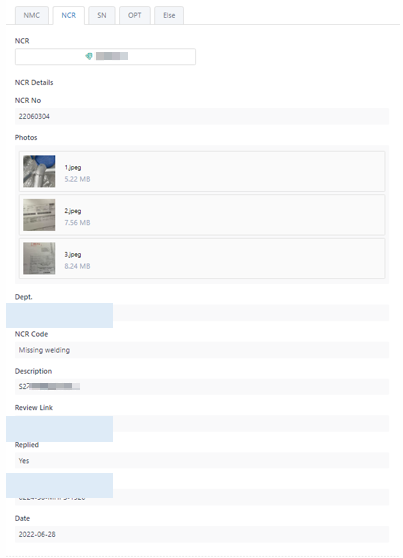

- Automatic Sync with ERP: They connected Jodoo directly to their Oracle ERP system. Whenever a new issue was logged into the ERP, the information instantly appeared in a Jodoo table. No more manual data entry.

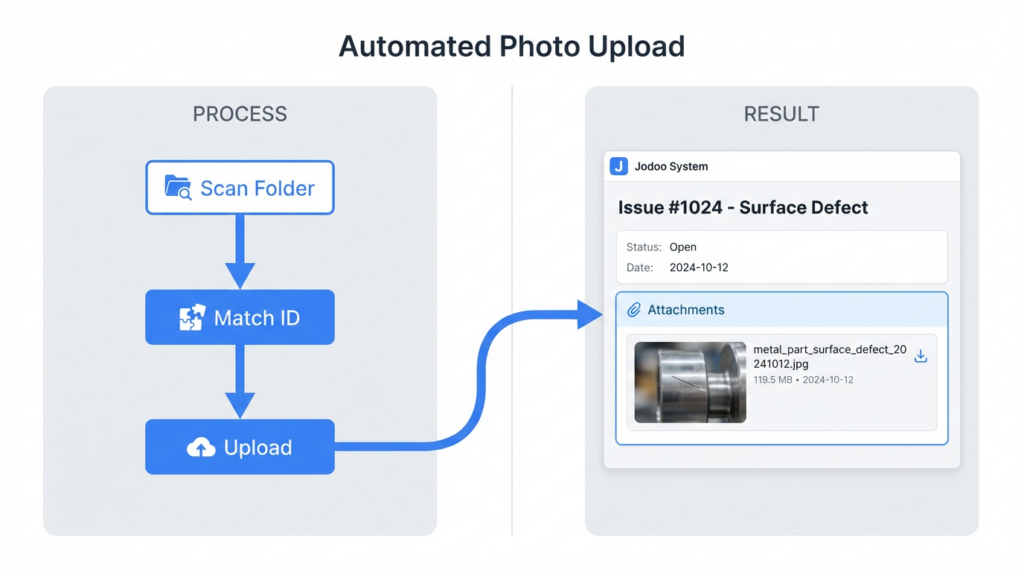

- Adding Pictures: They used a simple automation tool (UiPath) to automatically upload photos related to each issue and link them to the correct item in Jodoo. For the first time, everyone could see the problem, not just read about it.

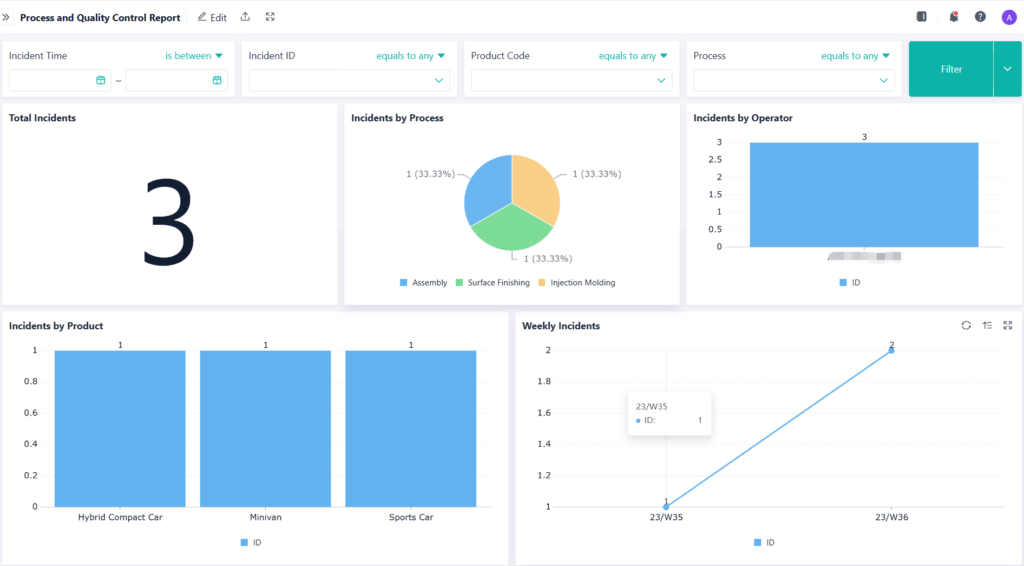

- Live Dashboards: All this information was displayed on a live Jodoo dashboard. Instead of waiting weeks for a report, managers could now see a real-time overview of all quality issues across the factory, updated daily. This visual approach made it easy to spot problems at a glance.

Fast Feedback from Anywhere

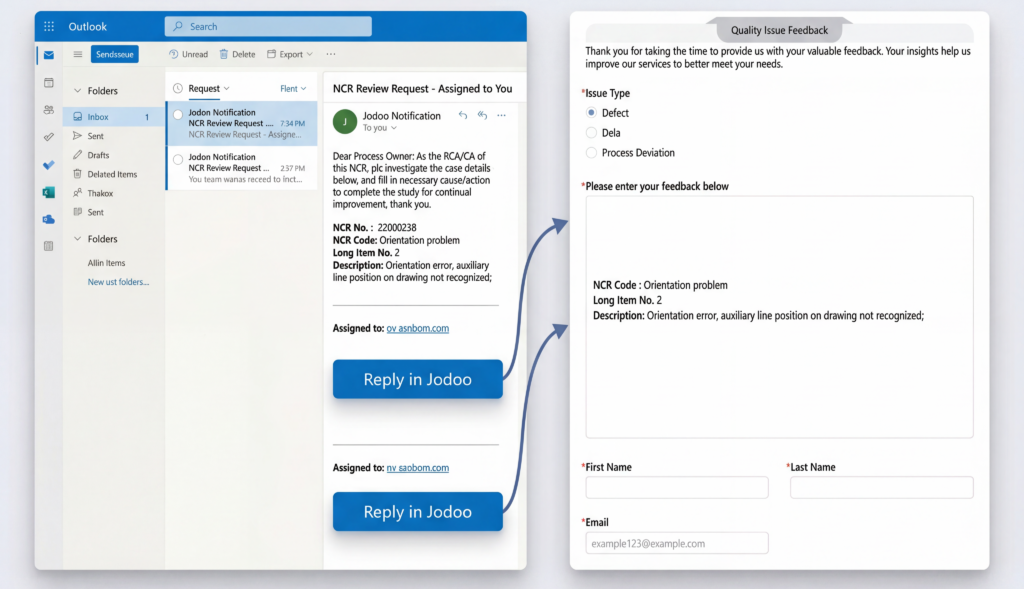

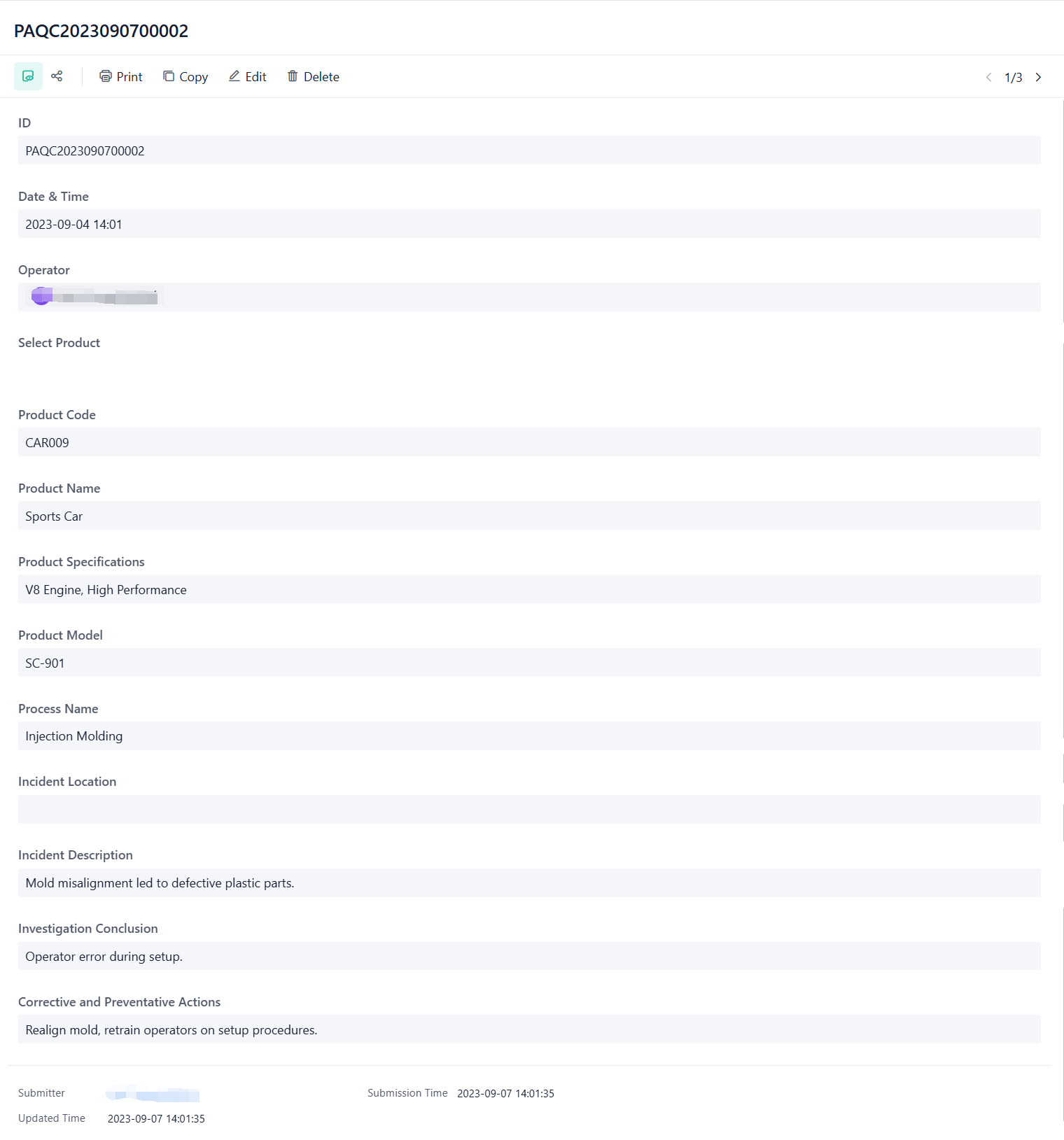

Next, they fixed the slow and difficult feedback process. They wanted to make it easy for team members to respond to issues, even when they were away from their desks.

They used Jodoo’s API and an email plugin to create a simple, mobile-friendly workflow. When a problem was assigned to someone, they received an email with a special link. They could simply click the link on their phone, type their update, and the information was instantly saved back to Jodoo.

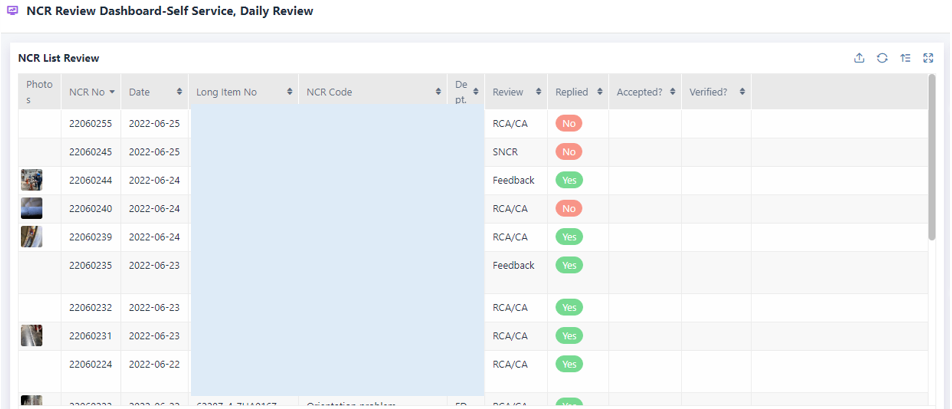

The status of the issue was automatically updated on the dashboard for everyone to see. This simple change made it easy to track progress and hold people accountable, and the reply rate for issues soared.

Turning Old Data into New Knowledge

Finally, the team unlocked the value of their historical data. They used Jodoo to create a smart, searchable database of every problem the company had ever faced.

Now, when a new issue came up, team members could quickly search for similar problems from the past. They could see what caused the issue, how it was fixed, and what the results were. This turned into a powerful training tool for new employees and helped everyone make better, faster decisions. The data that was once lost in old files was now a valuable asset, helping the company to learn from its past and prevent future mistakes.

This entire system was built and run by the quality team—the people who used it every day. It was a true example of business-led IT, made possible by the simplicity and power of a no-code platform.

The Results: A Faster, Smarter, and More Connected Factory

The changes at Cimtas were not just about new software; they were about a new way of working. By putting the power of digital tools in the hands of the business team, the company saw dramatic improvements in efficiency, communication, and problem-solving. The results speak for themselves.

The most impressive number was the 88.1% automation rate. The team took a process that used to require 42 minutes of manual work every day and reduced it to just 5 minutes. This dramatically reduced manual workload and the risk of human error, freeing the quality team to focus on higher-value analysis.

The 100% reply rate on issues was just as important. Before, problems could get lost or ignored. Now, every issue was tracked, and everyone was accountable. This created a culture of ownership and faster problem-solving.

But the biggest change was something you can’t measure on a chart: employee morale. As one team member put it, “The new digital tools didn’t just save us time; they freed us from boring, repetitive work. Our spirits have been lifted.”

Future Outlook: A Culture of Continuous Improvement, Powered by Data

For Cimtas, this is just the start. The success of the quality management system has shown everyone in the company what’s possible when you give the right tools to the right people. The experience has taught them some valuable lessons:

- Train Your People: New tools can be scary. Cimtas learned that it’s important to invest in training to help everyone feel comfortable with a new way of working.

- Let the Business Lead: The people who do the work know how to improve it. By letting business teams build their own solutions, you get better results, faster.

- Start Small, Think Big: You don’t need a perfect, all-encompassing plan to get started. Cimtas recommends starting with a few key applications, getting some quick wins, and then building from there.

Li and his team are already planning their next steps. They want to expand the use of Jodoo to other parts of the business, creating a fully connected digital factory. They see a future where data from every part of the company is used to make smarter decisions, improve processes, and drive even greater levels of quality and efficiency.

Cimtas’s story is a powerful example of how any company can become a digital leader. By embracing a culture of continuous improvement and empowering their employees with the right tools, they have built a smarter, faster, and more connected factory. They have shown that you don’t need a huge IT department or a massive budget to achieve a digital transformation. All you need is a clear vision, a willingness to change, and the right platform to bring your ideas to life.

Ready to empower your teams and build a smarter factory?