92%

Faster Sales Order Processing Time

99%

Shorter IT Issue Resolution Timeliness

33–50%

Reduction in Required Units for Production Test Bed Utilization

“When we were busy, the workshop often felt that three or four hundred test beds were not enough. After this system was launched, we found that 200 test beds were sufficient, significantly improving resource utilization.”

—Creality Production Team on Test Bed Optimization

| Metric | Before Jodoo | After Jodoo | Improvement |

|---|---|---|---|

| Sales Order Process Time | 3 Days | 6 Hours | 92% Faster |

| IT Issue Resolution Timeliness | Month-end | Immediate | Real-time |

| Production Test Bed Utilization | 300-400 units | 200 units | 33-50% Reduction in required units |

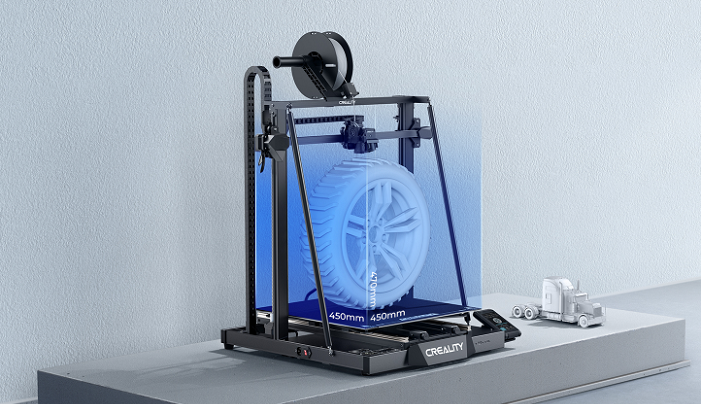

3D Printing: A Revolution in Manufacturing

3D printing, also known as additive manufacturing, is a groundbreaking technology that works differently from traditional “subtractive manufacturing”. Instead of cutting or carving materials to create a product, 3D printers build objects layer by layer using digital models. This process allows for precise control, efficient use of materials, and the ability to create complex designs that would be difficult or impossible with traditional methods.

One of the biggest advantages of 3D printing is its flexibility and cost-effectiveness, especially for small- to medium-scale production. It enables personalized manufacturing, improves production predictability, and minimizes material waste, making it a game-changer for industries seeking efficiency and sustainability.

Globally, 3D printing is being recognized as a key driver of industrial innovation. Many countries view it as a critical growth area for the future of manufacturing, particularly in the Industry 4.0 era, where smart technologies are reshaping production processes. Time magazine has named 3D printing one of the “10 fastest-growing industries in the United States,” and The Economist has highlighted it as a pivotal technology in the next industrial revolution.

Today, 3D printing is transforming industries such as aerospace, healthcare, dentistry, consumer goods, and industrial manufacturing. Beyond business applications, consumer-grade desktop 3D printers are becoming increasingly popular among hobbyists, educators, and DIY enthusiasts, opening up new possibilities for creativity and innovation at home and in classrooms.

Introduction: Creality—A Global Leader in 3D Printing Innovation

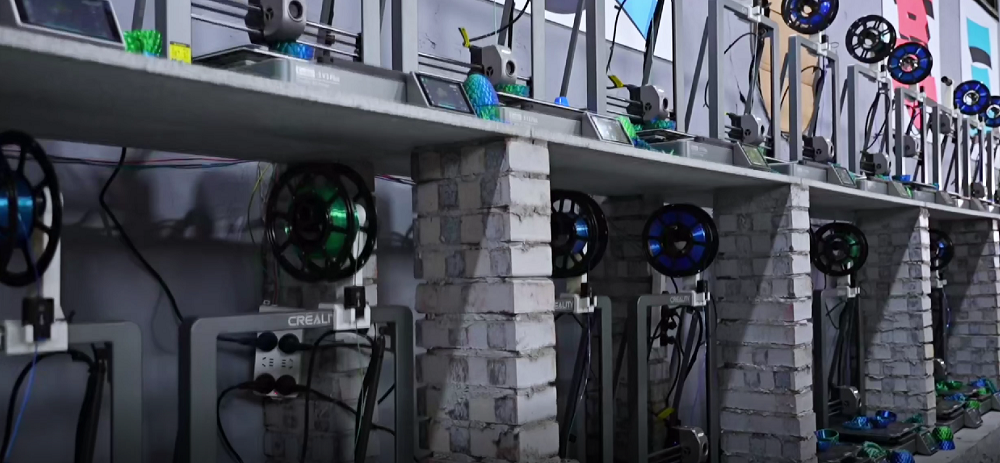

Creality stands as a global leader in the consumer-grade 3D printer market. Since its inception in 2014, Creality has rapidly grown, shipping over 5,000,000 3D printers worldwide. This remarkable growth has been underpinned by a strategic commitment to digitalization, ensuring that their operations remain agile and efficient in a dynamic global market.

Facing increasing production demands, the expansion into new factories, and the complexities of international development, Creality embarked on a comprehensive digital transformation journey. While foundational systems like SAP-ERP, OA, HR, SRM, PLM, and e-commerce OMS were established, the company sought a more flexible and efficient way to develop and integrate other critical business systems. Their solution: leveraging Jodoo’s no-code development platform to achieve business and goal alignment, streamline management processes, and drive continuous improvement through data-driven insights.

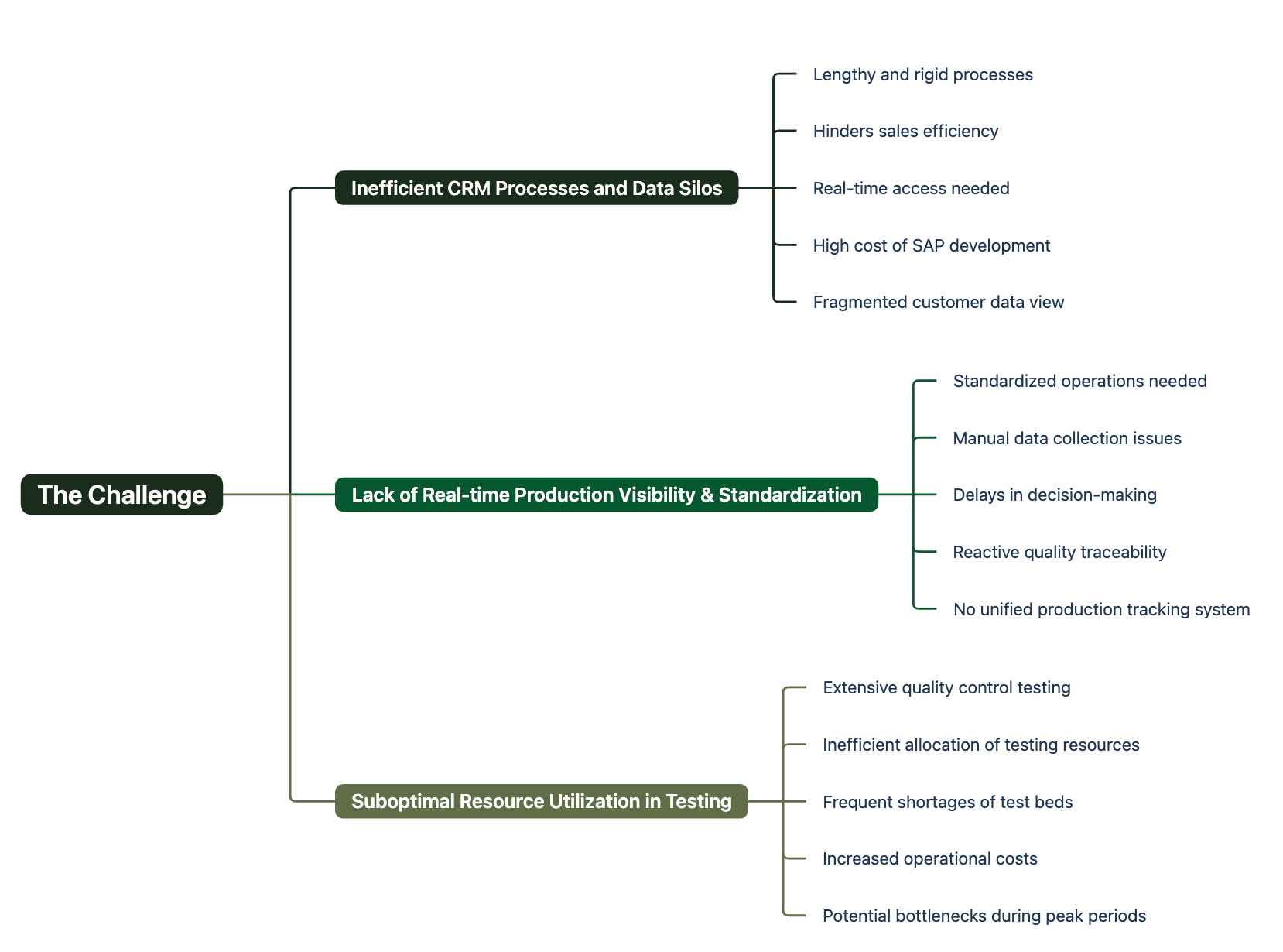

The Challenge: Bridging Gaps in a Rapidly Expanding Enterprise

As Creality scaled its operations, several key challenges emerged that traditional IT development and rigid enterprise systems struggled to address:

Inefficient CRM Processes and Data Silos

Creality’s existing CRM processes, particularly those integrated with SAP, were often lengthy and rigid, hindering sales efficiency and user experience. Sales teams needed real-time access to transaction statuses and customer issues, while leadership sought to optimize process flows. The high cost and complexity of secondary development within SAP made rapid iteration and customization difficult, leading to a fragmented view of customer data and prolonged approval cycles.

Lack of Real-time Production Visibility and Standardization

In the fast-paced 3D printer manufacturing environment, ensuring standardized production operations and real-time data collection was paramount. The intricate, multi-step assembly process required precise sequencing and quality control. However, manual data collection and reporting on production lines led to delays in decision-making, making it challenging for managers to monitor target completion, quantify risks, and allocate resources effectively. The absence of a unified system for tracking each stage of production meant that quality traceability and operational adjustments were reactive rather than proactive.

Suboptimal Resource Utilization in Testing

The quality control process for 3D printers involved extensive testing on dedicated test beds, with each model requiring approximately two hours for printing and LQC inspection. During peak periods, the workshop frequently faced shortages, often feeling that even 300-400 test beds were insufficient. This indicated an inefficient allocation and utilization of critical testing resources, leading to potential bottlenecks and increased operational costs.

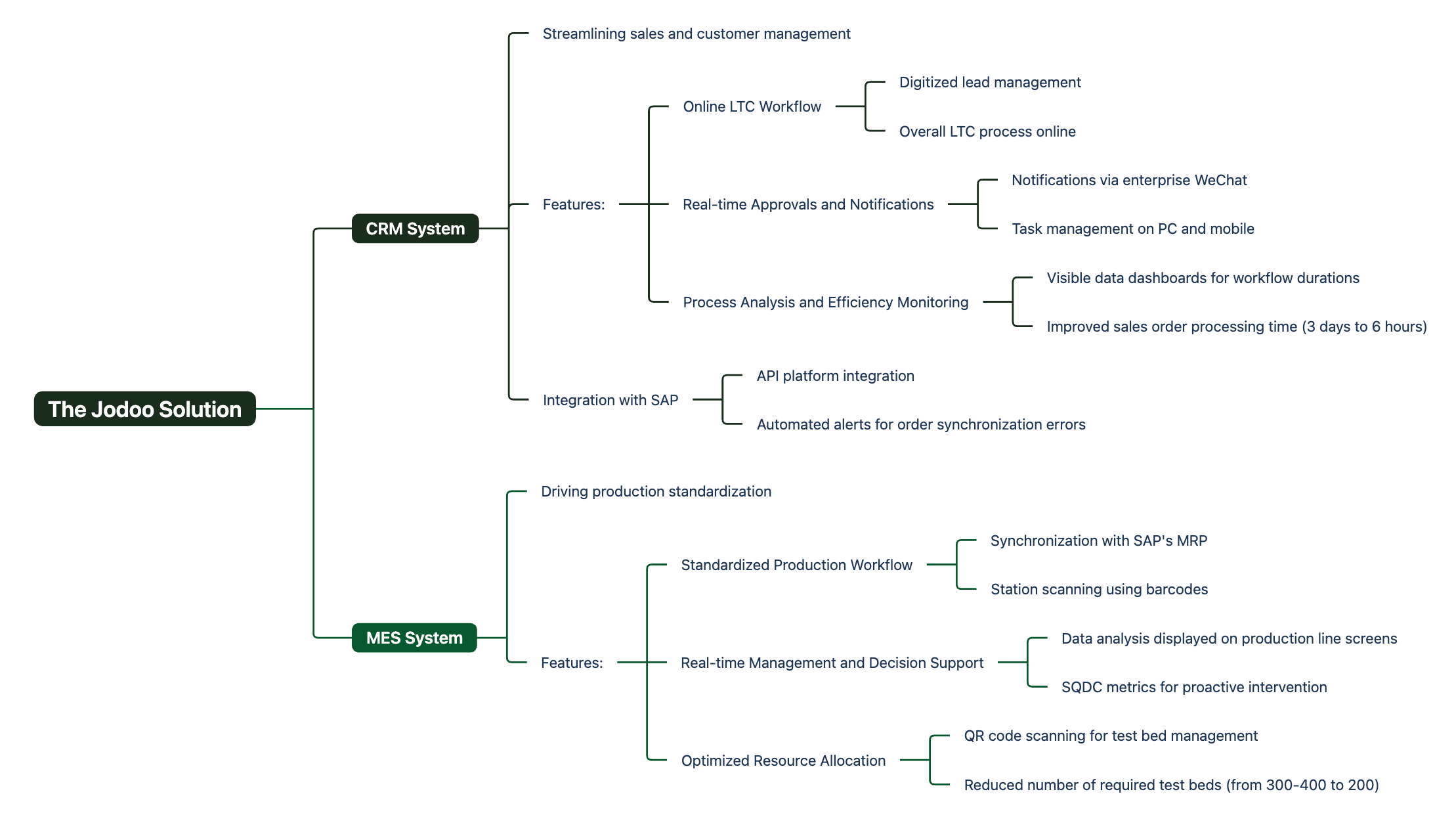

The Jodoo Solution: Empowering Agility and Efficiency with No-Code Development

To improve the user experience for business users and overcome the challenges of rigid SAP processes and complex secondary development, Creality partnered with Jodoo in 2022 to independently develop a CRM system focused on LTC((Lead-to-Cash) processes. Building on this success, the company expanded its use of Jodoo to create MES( Manufacturing Execution System), data reporting tools, and a cross-border OMS.

In 2023, Creality shifted its focus to ITR and ISC, using Jodoo to develop a CSC (Customer Service Center). Over time, the company implemented additional systems, including WMS, GTM, TMS, and QMS, to enhance the overall experience for customers, suppliers, and employees.

By leveraging Jodoo’s no-code platform, Creality was able to seamlessly integrate these applications into its existing enterprise architecture. The flexibility and rapid development capabilities of Jodoo enabled the company to address critical operational challenges, build customized solutions, and drive greater business agility and data-driven decision-making.

CRM System: Streamlining Sales and Customer Management

Creality developed a comprehensive CRM system using Jodoo, bringing their entire sales operation online and establishing a robust Lead-to-Cash (LTC) process. This system enabled:

- Online LTC Workflow: Digitizing lead management, business opportunities, quotations, and contracts, ensuring a complete online LTC process. This also facilitated the creation of customer information master data.

- Real-time Approvals and Notifications: Every step of the LTC process triggers notifications via enterprise messaging app, allowing employees to manage tasks on both PC and mobile, and enabling leaders to approve requests remotely.

- Process Analysis and Efficiency Monitoring: Jodoo’s process-analysis feature converts workflow durations into visible dashboards. As a result, employees shortened processing times voluntarily—for example, the sales-order process dropped from 3 days to an average of 6 hours.

This CRM system is also integrated with SAP via Jodoo’s API platform, feeding customer and order master data into SAP for production planning and displaying sales targets, forecasts, and delivery. Automated alerts for order synchronization errors, previously discovered only at month-end, now notify IT staff immediately, even on weekends, drastically improving issue resolution timeliness.

MES System: Driving Production Standardization and Data-Driven Decisions

Building on the success of the CRM implementation, Creality utilized Jodoo to develop a Manufacturing Execution System (MES), bringing their production execution online. This system addressed key needs in production operations:

Standardized Production Workflow: After SAP’s MRP run, production orders are synchronized to Jodoo’s dispatch forms, and barcodes are printed. These barcodes are used for “station scanning” at each stage of assembly, from motherboard aging tests to final LQC inspection and packaging. This ensures every device undergoes a thorough inspection before warehousing.

Real-time Management and Decision Support: Production managers can now view real-time data on computers and mobile devices, facilitating quality traceability. Data analysis results, integrated with Report Tool, are displayed on large screens across production lines, showing real-time SQDC (Safety, Quality, Delivery, Cost) metrics. This granular, hourly target management, with visual cues (green for on-target, red for improvement needed), enables proactive intervention. Persistent red indicators trigger patrol or improvement processes, ensuring closed-loop management.

Optimized Resource Allocation: By binding machines to test beds via QR code scans, Jodoo’s intelligent reminder function automatically notifies testers after two hours, releasing test beds for the next task. This optimization dramatically improved test bed utilization, reducing the required number from 300-400 to just 200 units, even during busy periods.

Conclusion: A Blueprint for Digital Transformation in Manufacturing

Creality’s journey with Jodoo exemplifies how a no-code platform can drive profound digital transformation in the manufacturing sector. By enabling the rapid development of tailored CRM and MES systems, Jodoo empowered Creality to:

- Achieve full-process business online, collecting master data for SAP and OMS systems.

- Realize online target management through seamless integration with Report Tool.

- Significantly enhance process approval and problem-solving efficiency, leading to a superior business user experience.

This strategic adoption of Jodoo has not only streamlined Creality’s operations but also provided a flexible, scalable foundation for future growth and innovation. For manufacturing executives seeking to optimize their operations, improve efficiency, and foster a data-driven culture, Creality’s success story offers a compelling blueprint.

Ready to streamline your process and make better decisions with no-code innovation? Discover how Jodoo can help your business achieve similar success.