95%

Reduction in Development & Operating Costs

1-2

Days for Implementation

0

Maintenance Costs for System Updates

“Jodoo supports modules requiring real-time statistical analysis report display, such as incoming quality inspection, in-process inspection, gauge management, system audits, layered process audits, and supplier management. It features a user-friendly interface, powerful data statistical analysis capabilities, a no-code development platform, a low learning curve,and development and operating costs that are just 5% of the cost of traditional development and operations.”

— EFORT Intelligent Equipment

EFORT Intelligent Equipment is a leader in intelligent manufacturing and a top-tier player in industrial robotics. It offers cutting-edge industrial robots and cross-industry smart manufacturing solutions to diverse clients. Globally, it has 19 subsidiaries in Asia (China, India), Europe (Italy, Germany, France, Poland), and South America (Brazil). This global scale reflects EFORT’s commitment to enterprise quality management and optimizing global management systems.

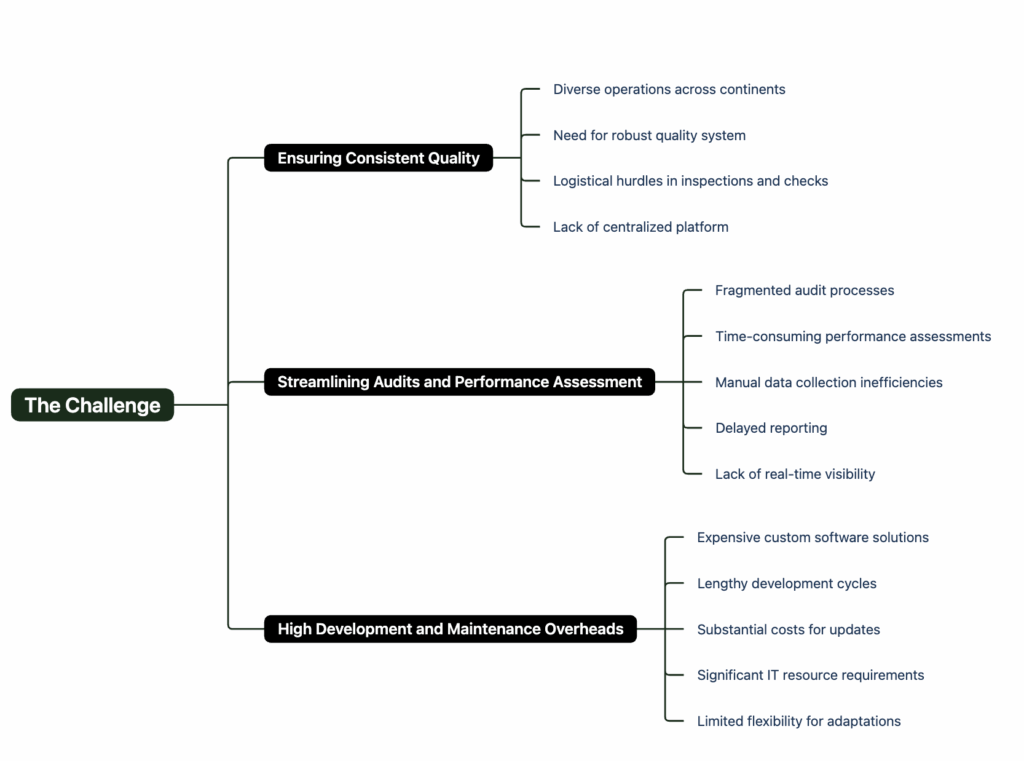

The Challenge: Navigating Complexity in Global Quality Management

As a global leader in industrial robotics and intelligent manufacturing solutions, EFORT faced the inherent complexities of maintaining a unified and efficient quality management system across its vast international network of 19 subsidiaries. The traditional approaches to quality control often struggled to keep pace with the dynamic demands of a rapidly evolving manufacturing landscape. Key challenges included:

Ensuring Consistent Quality Across Diverse Operations

With operations spanning multiple continents and diverse manufacturing processes, EFORT needed a robust system to ensure consistent quality standards. Managing incoming materials inspections, in-process quality checks, and gauge calibration across different regions presented significant logistical challenges and data integration hurdles. The lack of a centralized, adaptable platform made it difficult to standardize procedures and enforce compliance uniformly.

Streamlining Audits and Performance Assessment

The process of conducting system audits, layered process audits, and performance assessments was often fragmented and time-consuming. Manual data collection and analysis led to inefficiencies, delayed reporting, and a lack of real-time visibility into quality performance. This hindered EFORT’s ability to proactively identify and address quality issues, impacting overall operational agility.

High Development and Maintenance Overheads

Developing and maintaining custom software solutions for each quality management module was proving to be prohibitively expensive and slow. Traditional development cycles were lengthy, and any updates or iterations to the system incurred substantial costs and required significant IT resources. This limited EFORT’s flexibility to adapt its quality management system to new requirements or optimize existing processes efficiently.

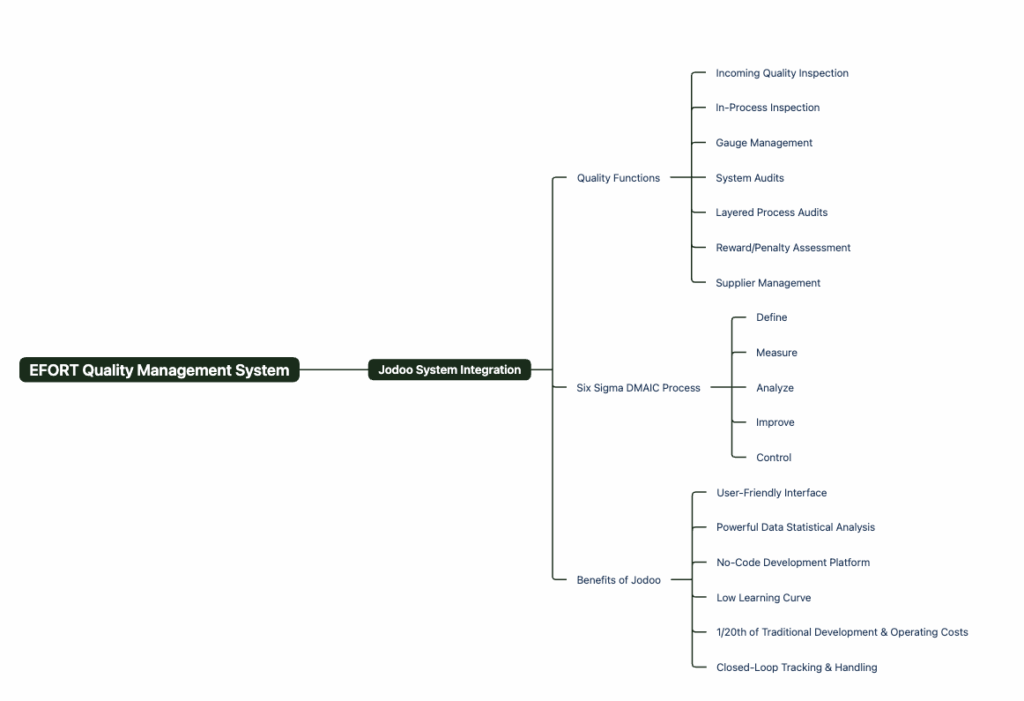

The Solution: Jodoo’s No-Code Platform for Integrated Quality Management

To address these multifaceted challenges, EFORT strategically partnered with Jodoo, leveraging its powerful no-code development platform to establish a comprehensive and integrated quality management system. Jodoo’s solution enabled EFORT to modularize its quality functions, bringing unprecedented efficiency and adaptability to its global operations. The implementation centered around several key aspects:

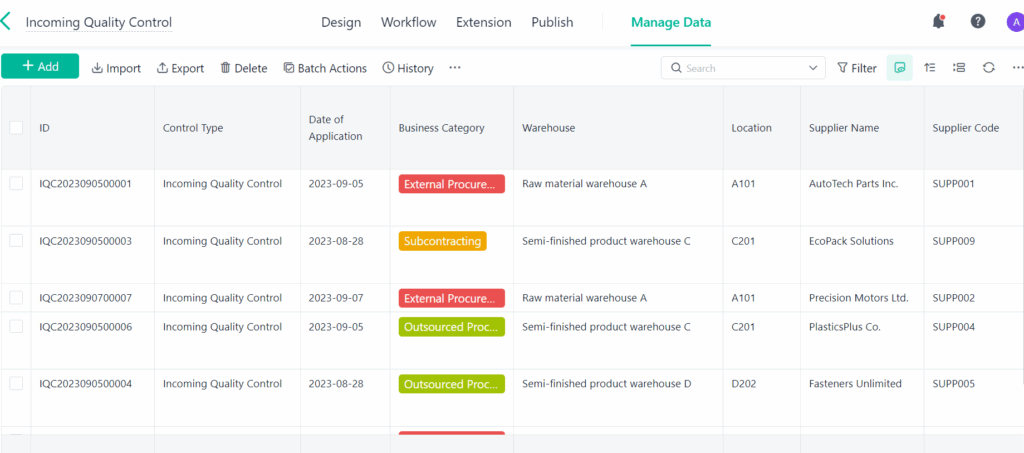

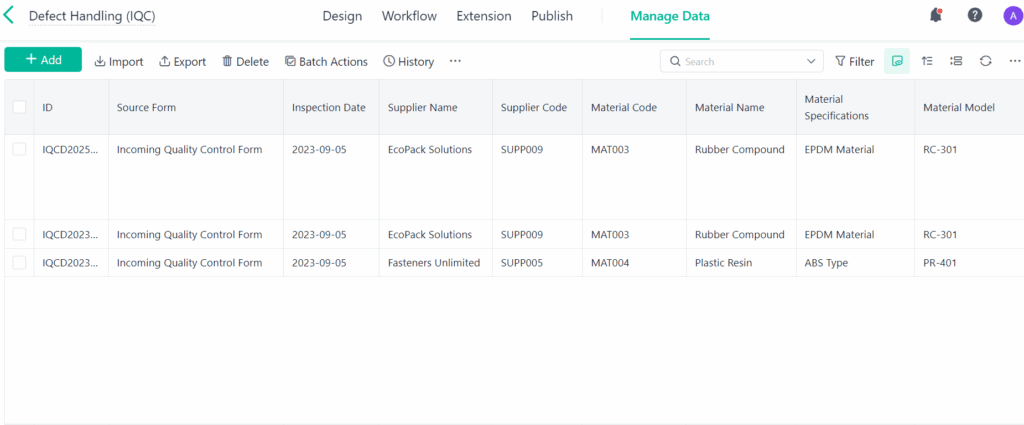

Incoming Material Inspection

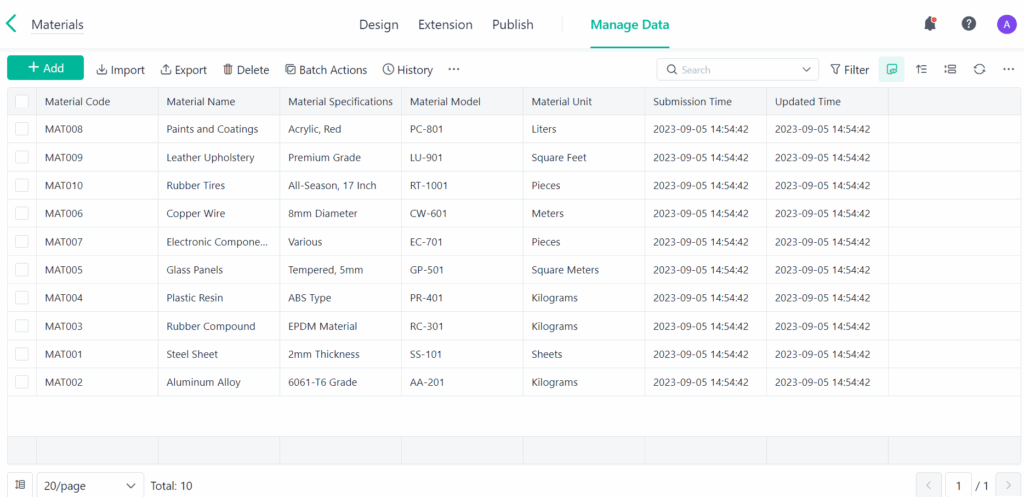

EFORT configured a comprehensive Incoming Material Inspection module to act as a centralized hub for all receiving-related activities. Beyond standard process and BI reports, a Document Library was integrated directly into the application. This allows inspectors and engineers to instantly access material requirement documents and specifications, streamlining the entire inspection process.

Furthermore, the module leverages Jodoo’s flexibility to solve issues that previously required cumbersome Excel workarounds. Custom print templates were created for quality training notices, notifications, and supplier claim forms, all generated directly from the system. A key highlight is the use of relational data: when an inspector enters a material number and supplier, the system automatically displays all historical quality issues associated with that combination, providing critical context for better analysis. Finally, custom-printed delivery notices now include a QR code, which staff can scan with their phones to retrieve detailed information instantly.

Supplier Return Management

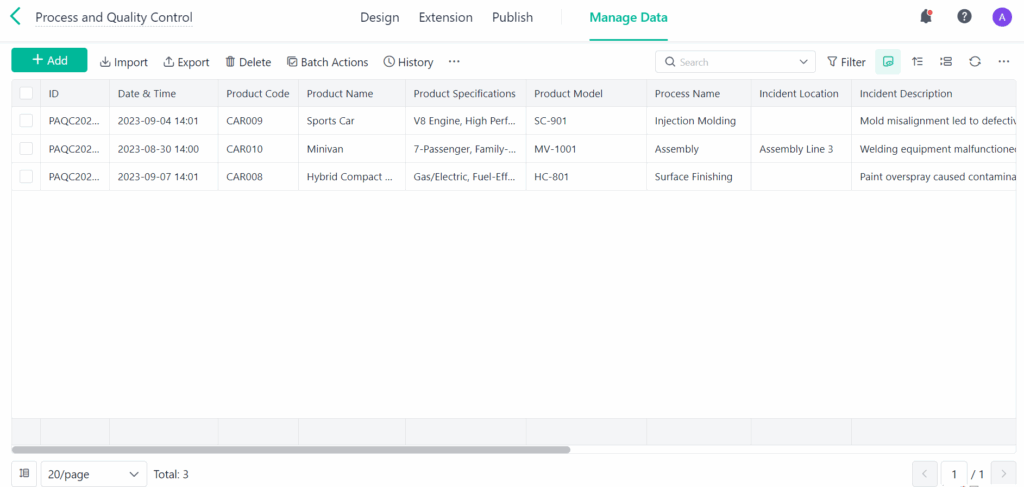

With a high volume of daily supplier returns, EFORT’s original process—manually tagging items, delaying data entry into SAP, and sending periodic reports—was prone to errors and inventory discrepancies.

Using Jodoo, the return process was linked directly to in-process quality issues. Now, when a quality issue is logged and the disposition is set to “Return to Supplier,” the system automatically triggers a dedicated return workflow, notifying materials staff, supplier quality engineers (SQEs), the warehouse, and procurement. The entire process is managed within Jodoo, ensuring all stakeholders are synchronized. This workflow is dynamic: if the quality issue’s disposition changes, the return process is updated or even canceled automatically.

To enhance traceability, staff attach a Jodoo-generated QR code to each returned item. Anyone—both internal teams and external suppliers—can scan the code to view the reason for the failure and track the real-time status of the entire return process.

Gauge & Calibration Management

EFORT replaced its unreliable Excel-based logs for gauge management. Previously, staff would often forget to check the spreadsheet, leading to overdue calibrations and compliance risks. The new Gauge & Calibration Management application, built on Jodoo completely solves this. A key function is managing the gauge lifecycle, where the system sends automated reminders and notifications to responsible personnel before a calibration date is due—a proactive feature not achievable with standard office software.

This module is part of a larger vision at EFORT to create a comprehensive quality system, inspired by frameworks like BIQS (Built-In Quality Supply). Other modules include Customer Complaints, Quality Rewards/Penalties, Deviation Permits, and Change Management. The goal is to ensure that the company’s quality management system is not just a set of documents, but a living, actionable framework that is continuously improved based on the principles of Joseph Juran’s quality philosophy.

Enterprise Document Control

To manage its QMS documents and audit processes, EFORT built a dedicated Enterprise Document Control application. This module centralizes company-level and department-level documents, approval workflows, training materials, and the audit management system (for both internal and external audits). This solves the critical issue of inaccurate and delayed document updates common with files stored on local network drives.

When audits are conducted, any findings are logged into the system using standardized templates. The subsequent corrective actions are then tracked through a digital workflow, eliminating manual, offline follow-ups and ensuring efficient resolution. The application also serves as a one-stop hub for standards, training materials, and audit templates.

Transformative Results: Driving Operational Excellence with Jodoo

The integration of Jodoo into EFORT’s quality management framework has yielded significant and measurable improvements, solidifying the company’s position as an innovator in intelligent manufacturing. These advancements are not merely incremental; they represent a fundamental shift in how EFORT manages quality, fostering greater efficiency, agility, and cost-effectiveness across its global operations.

Drastic Reduction in Development and Operating Costs

One of the most immediate and impactful benefits EFORT realized was a 95% reduction in development and operating costs. Jodoo’s no-code platform eliminated the need for extensive, specialized programming, allowing EFORT’s teams to build and deploy custom quality applications with minimal resources. This cost efficiency extends beyond initial development, encompassing ongoing maintenance and operational expenditures, freeing up valuable capital and human resources for other strategic initiatives.

Accelerated Module Development and Deployment

Jodoo has dramatically shortened the development cycle for new quality management modules, reducing the time from months to just 1-2 days per module. This rapid development capability empowers EFORT to respond swiftly to evolving market demands, regulatory changes, and internal process improvements. The ability to quickly iterate and deploy new applications ensures that EFORT’s quality systems remain cutting-edge and perfectly aligned with its operational needs, providing a significant competitive advantage.

Elimination of System Iteration and Update Maintenance Costs

Perhaps most impressively, EFORT has achieved zero maintenance costs for system iteration and updates. The inherent flexibility and ease of modification within Jodoo’s no-code environment mean that updating existing applications or iterating on new features no longer incurs the substantial maintenance overhead associated with traditional software. This not only translates to direct cost savings but also ensures that EFORT’s quality management system is always current, optimized, and free from technical debt, supporting continuous improvement without financial burden.

Beyond these quantifiable metrics, EFORT has also experienced enhanced data visibility, improved collaboration across its global subsidiaries, and a more proactive approach to quality control. The user-friendly interface and powerful analytical tools of Jodoo have democratized access to critical quality data, enabling more informed decision-making at all levels of the organization.

Conclusion: A Future of Optimized Quality and Innovation

EFORT’s journey with Jodoo exemplifies how leading industrial enterprises can leverage no-code platforms to revolutionize their quality management systems. By embracing Jodoo, EFORT has not only overcome significant operational challenges but has also established a scalable, cost-effective, and highly efficient framework for continuous quality improvement. The ability to rapidly develop, deploy, and maintain complex applications without traditional coding has positioned EFORT at the forefront of intelligent manufacturing, ready to tackle future demands with agility and confidence.

This partnership showcases Jodoo’s potential to drive digital transformation in the construction and manufacturing industries, enabling companies like EFORT to achieve operational excellence, reduce costs, and foster innovation across their global footprints. The success story of EFORT and Jodoo serves as a compelling blueprint for any organization seeking to optimize its quality processes and unlock new levels of efficiency in a competitive global market.

Ready to transform your quality management and accelerate your digital journey like EFORT? Discover how Jodoo can empower your business with no-code innovation.