99.9%

Reduction of Critical Report Cycle Time

21%

Improved HR Process Efficiency

70%

Increase in Employee Management Participation

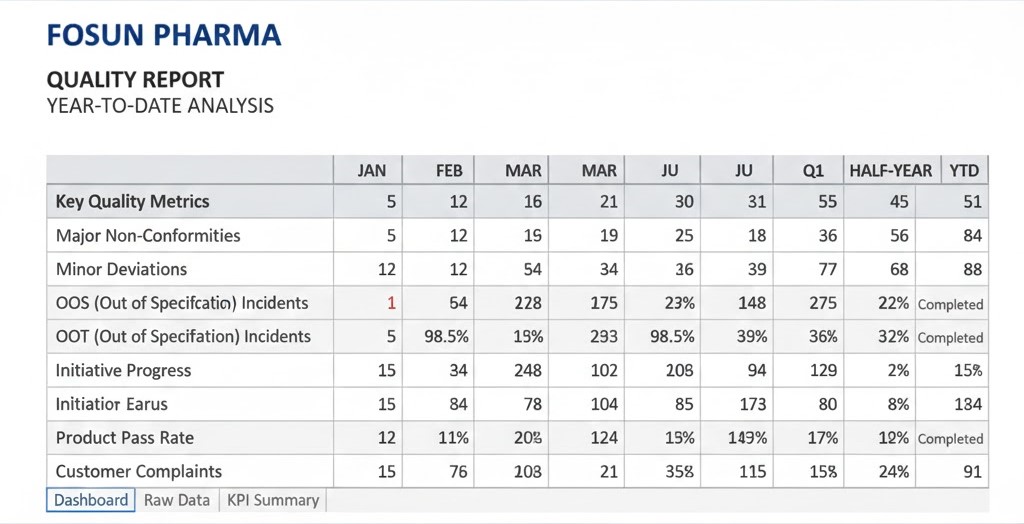

Fosun Pharma, an innovation-driven global healthcare industry group, is a leading player in the global pharmaceutical sector. Founded in 1994, the innovation-driven group has grown into a comprehensive enterprise with a presence in pharmaceuticals, medical devices, diagnostics, and healthcare services, employing over 40,557 professionals worldwide and generating 5.9 billion USD in revenue in 2024.

The Challenge: How a Global Pharmaceutical Leader Broke the Bottleneck of Manual Processes

The Group’s success is rooted in strategic acquisitions, a commitment to quality, and its enduring mission of “Better Health for Families Worldwide.”However, as the drug program shifted dramatically, profit margins narrowed, and the need to invest significantly in innovative drug research and development grew more urgent. This market reality forced a strategic pivot: Fosun Pharma moved from a focus on “scale expansion” to “lean breakthrough”.

The Group’s Lean Operations Department, which oversees more than 40 member enterprises, was tasked with driving this efficiency. Yet, the very processes designed to enforce lean management were themselves a source of massive inefficiency, creating a significant bottleneck at the operational level.

The Paperwork Paradox: Manual Processes Stalled Digital Ambitions

Like many large and diversified conglomerates, Fosun Pharma faced a “paperwork paradox.” While the Group possessed a mature internal IT team and self-developed core business systems (ERP, BI), the day-to-day, non-core processes—the “last mile” of operational management—were still mired in manual, time-consuming methods.

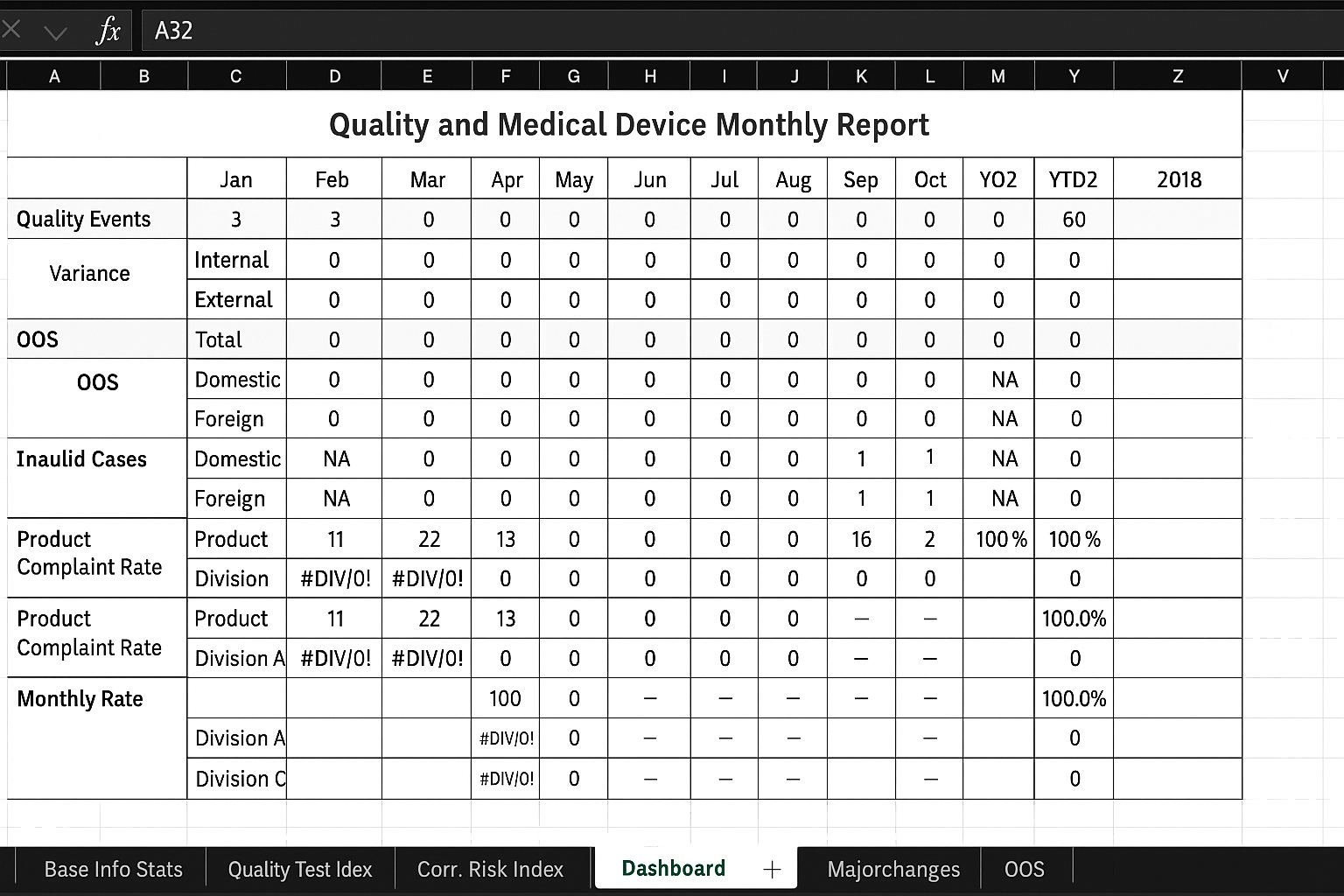

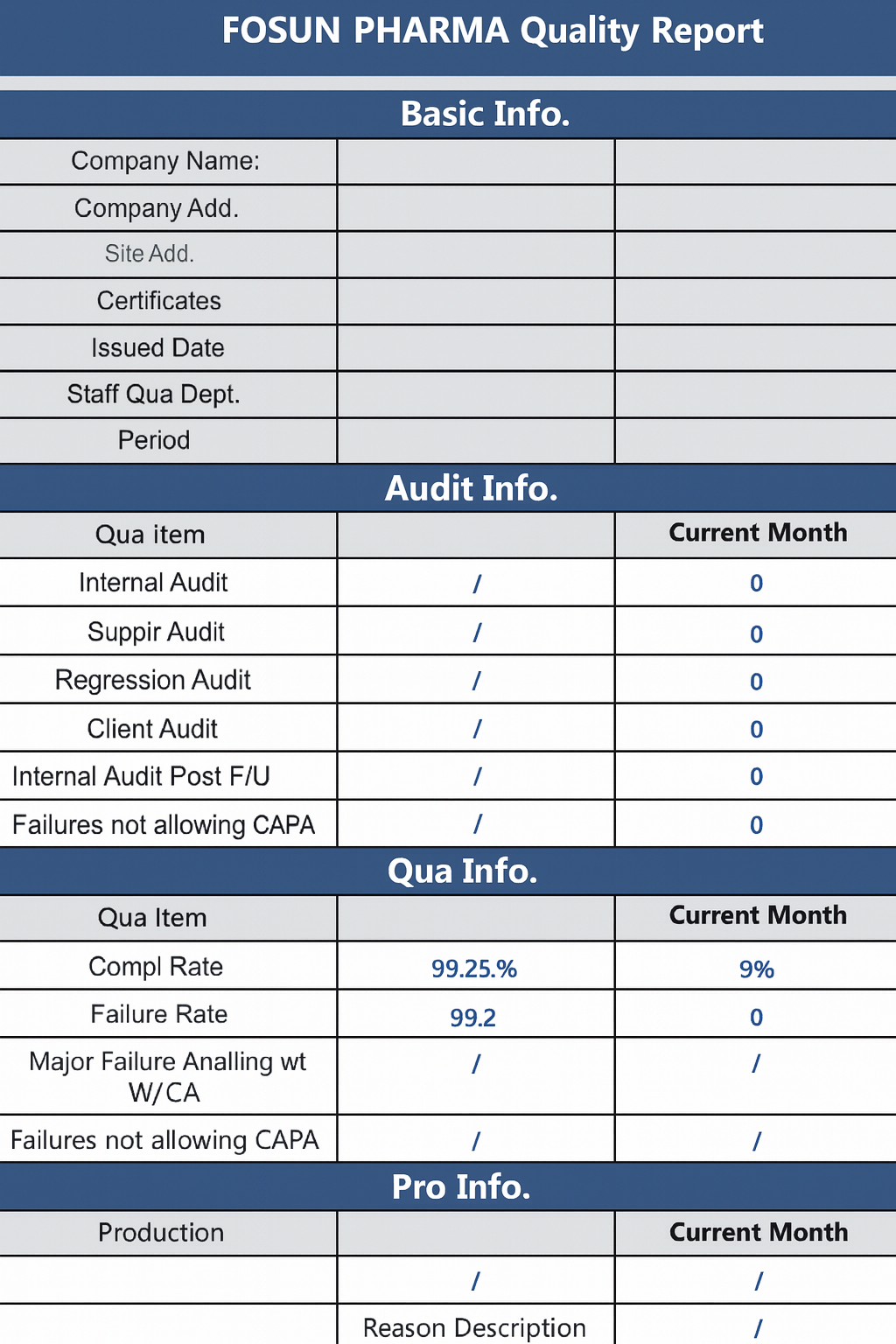

The most critical pain point centered on Quality and Device Monthly Reporting. As a pharmaceutical company, quality is the absolute red line, and the Group requires strict, timely data from its numerous member enterprises.

“The monthly collection of quality data from over 40 enterprises was a nightmare,” recalls Mr. Liu, a key IT specialist at one of the member companies, ERYE Pharmaceutical. “The process relied on member companies emailing Excel or PowerPoint documents. We would then have to manually aggregate, clean, and consolidate these reports into a master file with over 200 fields. Data quality was low, some used numbers, some used characters, and the interpretation of fields varied widely.”

This manual chaos led to three major problems that directly undermined the lean initiative:

- Crippling Latency: Over 40 subsidiaries collect data and submit it via email, often in disparate Excel or PowerPoint files. The time from data submission to the final report being ready for executive review took two to three weeks. This severe delay meant that management decisions were based on stale data, making proactive intervention impossible.

- High Labor Cost and Error Rate: A dedicated team at the headquarters would spend weeks manually collating, cleaning, and validating the data. They need to chase down missing reports, clean inconsistent data, standardise formats, and manually calculate weighted sums. This labor-intensive effort was highly prone to human error, consuming thousands of man-hours annually and diverting valuable resources from higher-value tasks.

- Digital Silos and Low Engagement: The final reports were often static documents, difficult to share with varying levels of access, and nearly impossible to integrate with the Group’s Business Intelligence (BI) systems in real-time. Furthermore, frontline employees had no easy, digital way to submit ideas or participate in the lean process.

The Search for the Right Tool: A Costly Lesson in Rigidity

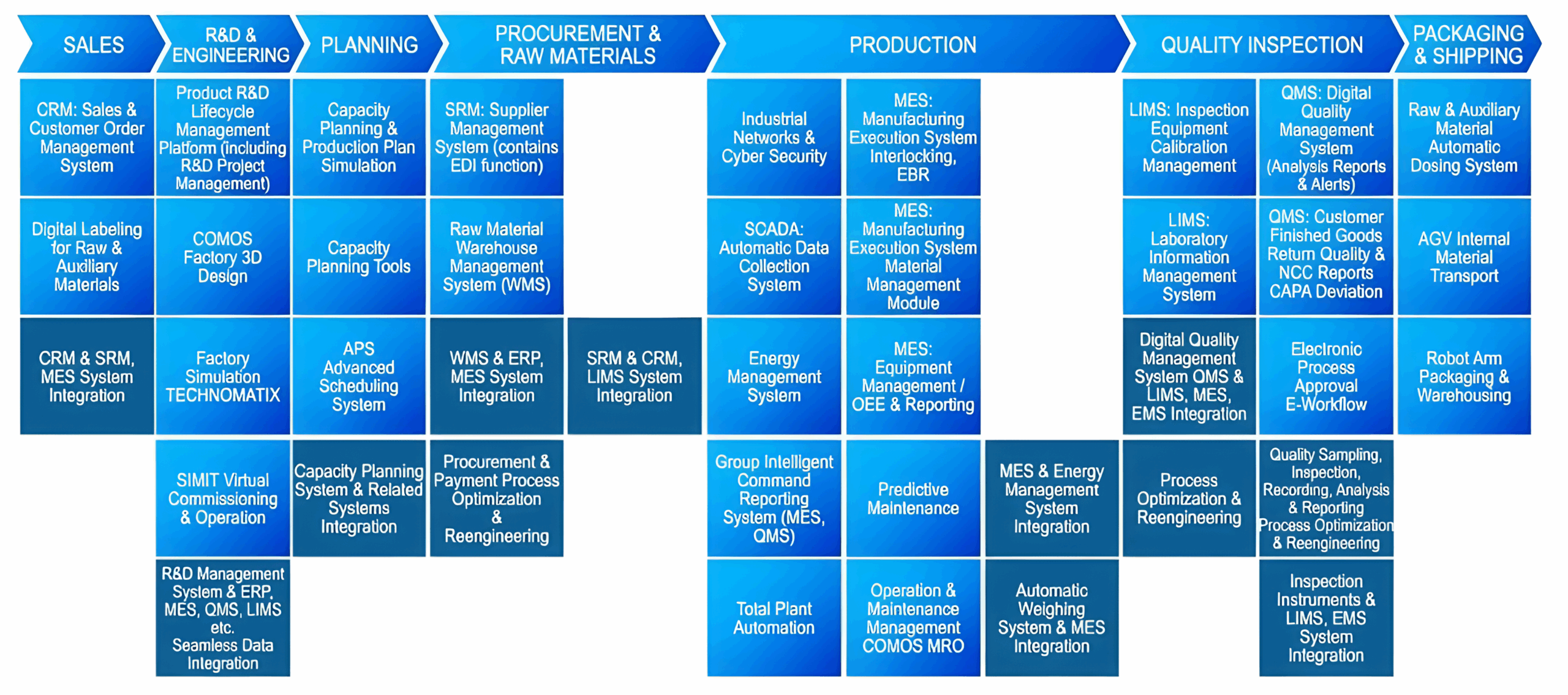

By 2019, Fosun Pharma already possessed a mature IT infrastructure, with core business systems—such as ERP, sales, and logistics—developed in-house or procured as best-of-breed solutions. However, these systems, while robust, acted as isolated “blocks” on the “plane” of business information.

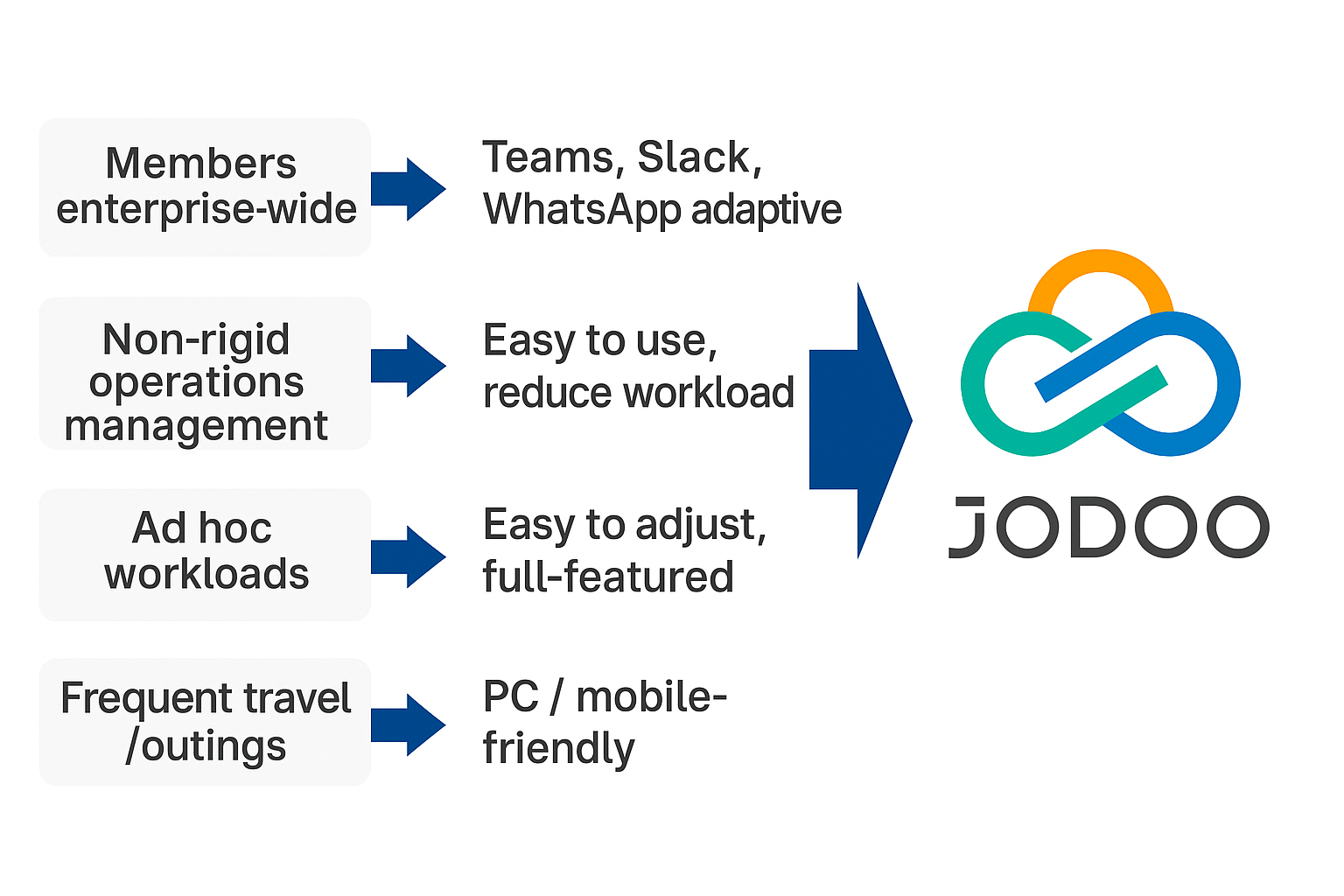

Fosun Pharma’s Chief Digital Officer, Mr Lin, clearly articulated the challenge: the Group needed a solution that could bridge the “last mile” between the centralised IT function and the dynamic, ever-changing needs of the business and its frontline users.

Prior attempts to address this challenge with custom-coded systems were unsuccessful. A major initiative launched in 2019, which required substantial investment and a long development cycle, was ultimately deemed too rigid:

“We had a BI system that, after a year of implementation, still wasn’t delivering the required reports effectively. The cost of maintaining and iterating on custom code was simply unsustainable for the sheer variety of processes across our subsidiaries. We realized that if we were to truly empower our business units, we needed to shift the power of application building away from the central IT team.“

— A User from the Lean Management Department

Fosun Pharma recognized that to truly achieve a “digital lean” transformation, they needed a platform that offered flexibility to adapt to the unique needs of each member company and the efficiency to deploy new applications in days, not months.

The Solution: Empowering Business Users with a No-Code Ecosystem

In 2021, Fosun Pharma introduced Jodoo, a no-code development platform, to address these critical gaps. The decision was strategic: the Group decided to empower business users to build and iterate on applications themselves, freeing the central IT team from the burden of constant change requests.

The Quality Report System: From Weeks to Minutes

The first and most impactful application developed on Jodoo was the new Quality and Medical Device Monthly Report System.

Key Features of the Solution:

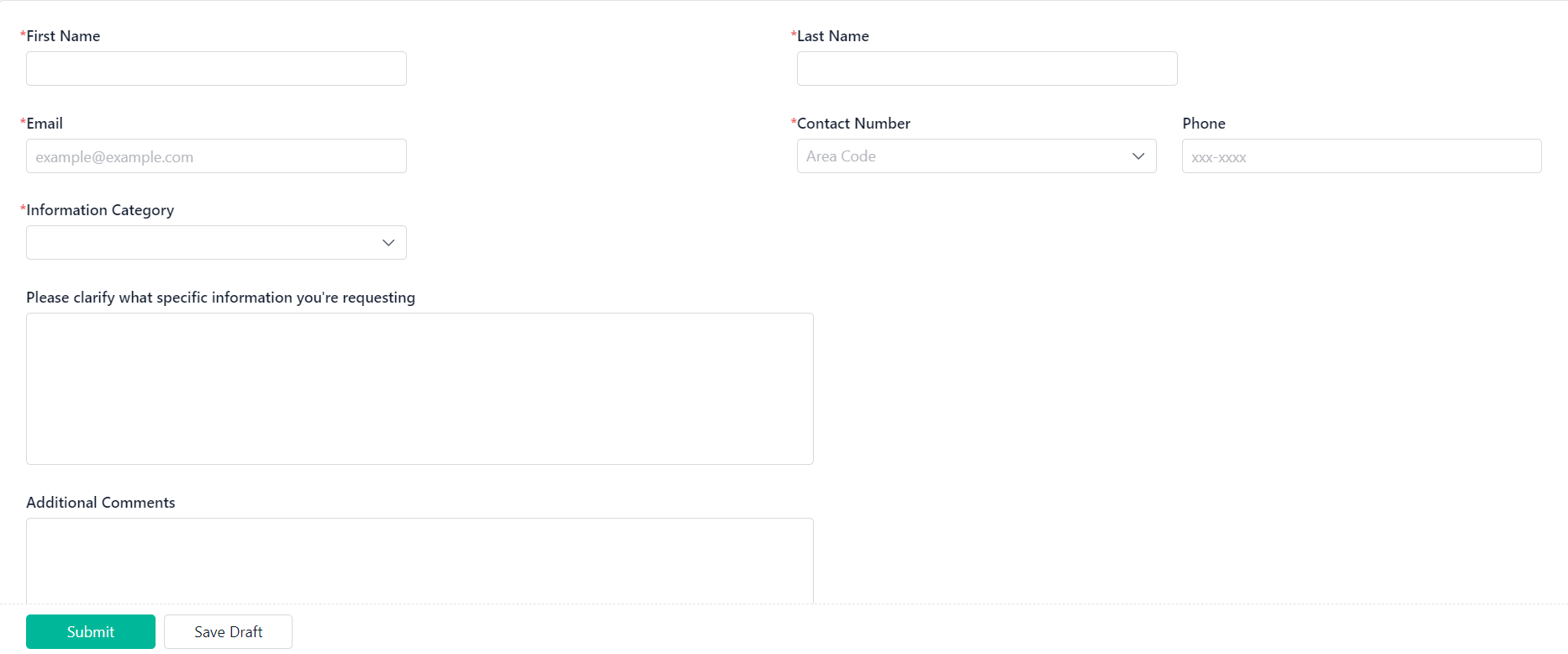

- Mobile-First Data Entry: The system was integrated with the Group’s internal communication tool (Teams), allowing quality personnel at the member companies to fill out the report forms directly on their mobile devices.

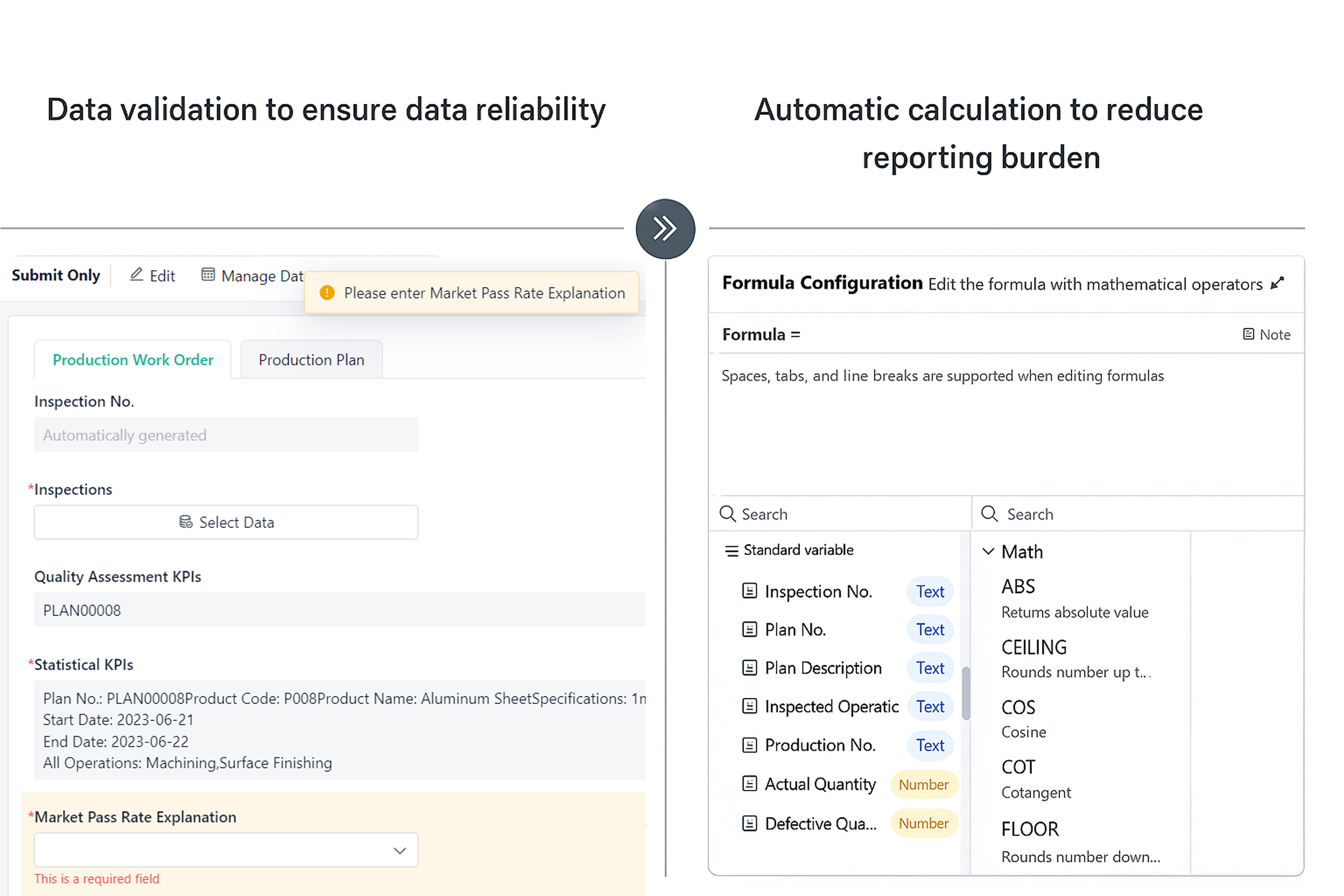

- Built-in Data Validation and Calculation: The Jodoo forms included embedded calculation formulas and data validation rules. This eliminated the need for manual calculations and ensured that data was entered in a standardized format, preventing the previous issues of inconsistent formats (numbers vs. text) and misinterpretation of fields.

- Automated Aggregation and BI Sync: Once a member company submitted its report, the data was instantly aggregated at the Group level. This real-time data was then automatically synchronized with the Group’s core BI system, effectively bypassing the manual data cleaning and consolidation process entirely.

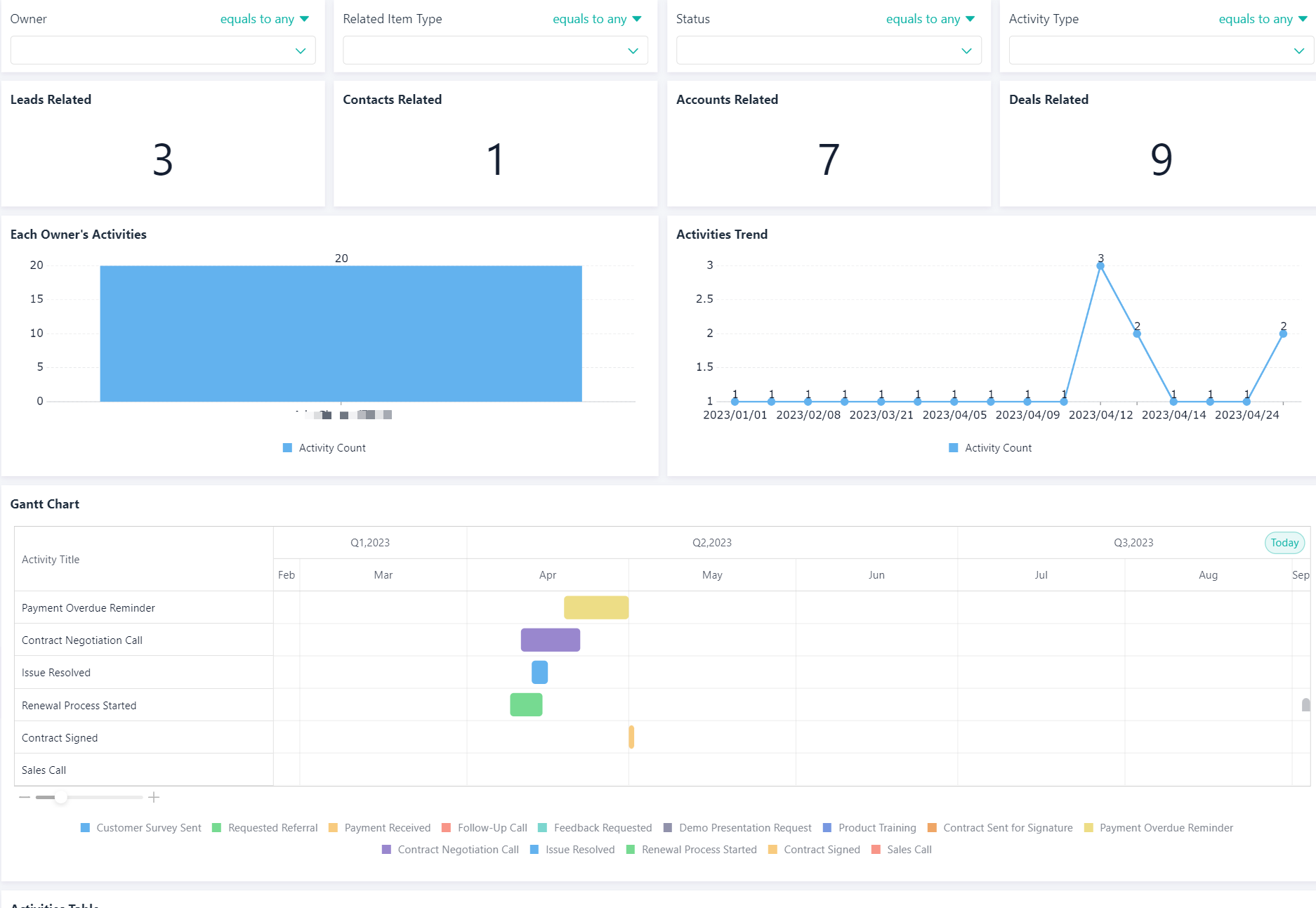

- Dynamic Dashboards: The manual, static reports were replaced with dynamic dashboards accessible by executives on their mobile phones, providing real-time visibility into the quality status of all member companies.

The success story of the Quality Report also established a crucial internal best practice: “Achieve good results first.” The champion user, facing initial scepticism from leadership:

“My manager preferred Excel, even though it takes 2-3 weeks. Because he believed that once employees became skilled, the process could be reduced to 1 week. But I insisted and convinced him to try Jodoo. Now, he’s a fan and proudly shares Jodoo as an example of our advanced practices.“

— A User from the Lean Management Department

The Lean Management Ecosystem: Fostering Bottom-Up Innovation

ERYE Pharmaceutical, a key member enterprise, became a showcase for the platform’s potential, developing over 20 applications and 60 processes on Jodoo. Their focus was on creating a comprehensive Digital Lean Management Platform to drive continuous improvement from the ground up.

“Jodoo has fundamentally changed the way we build information systems,” states Mr. Wan, IT Director at ERYE. “We can now authorize business departments or member company IT to build applications, allowing us to focus more on business optimization rather than spending energy on code development.“

The platform addressed the three core challenges of traditional lean management:

| Traditional Pain Point | Jodoo Solution | Functionality | Value |

|---|---|---|---|

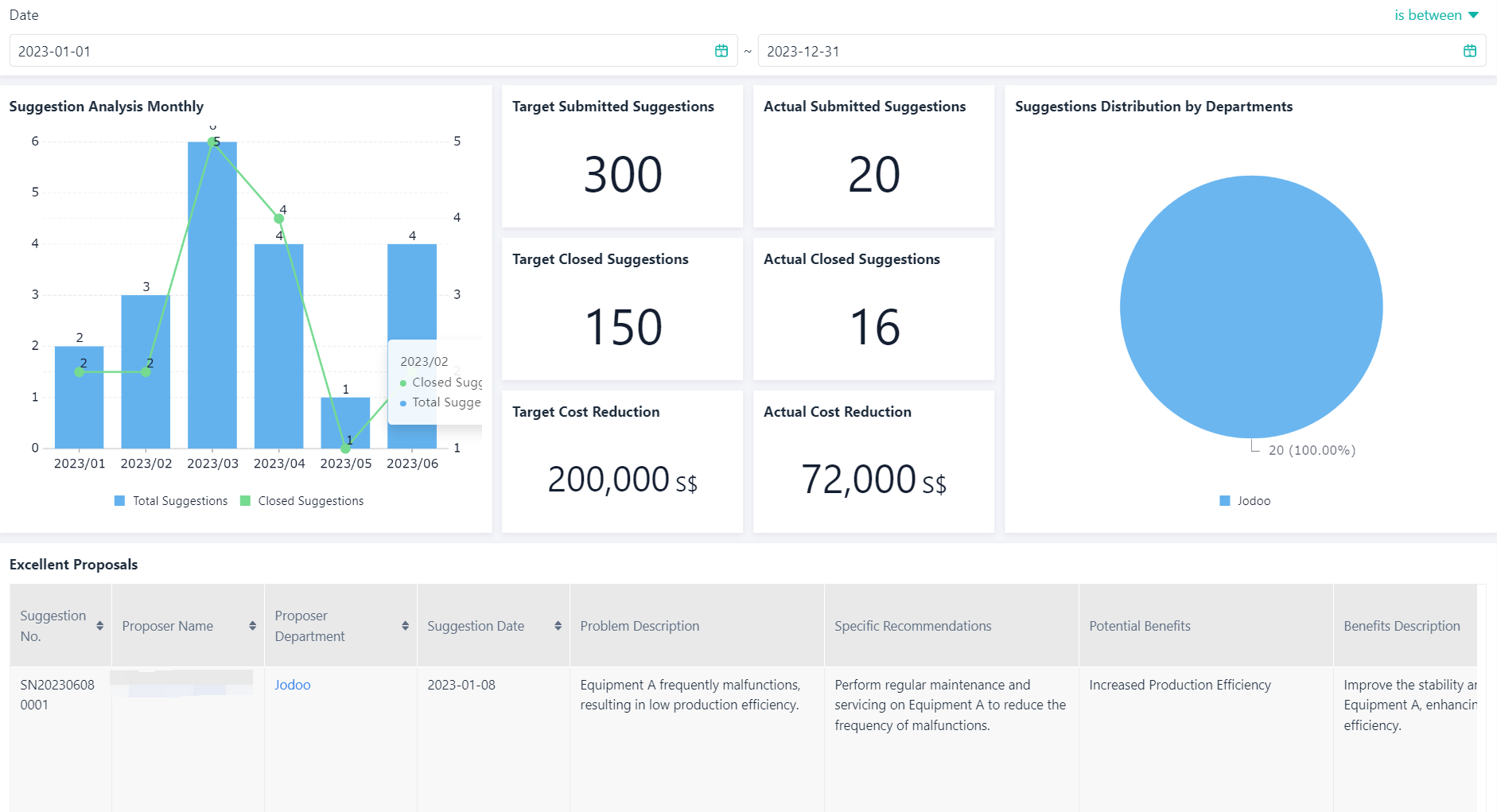

| Low Employee Engagement (Paper-based suggestions, no feedback) | “Golden Idea” Submission | Frontline employees submit improvement suggestions (text, images, video) via mobile. The system automatically classifies and routes the idea to the responsible department for evaluation. | Encourages grassroots innovation and provides a clear feedback loop. |

| Project Tracking Opacity (Manual tracking, hard to quantify results) | End-to-End Project Management | Full-process online management for approved ideas, covering project approval, task assignment, progress tracking, and final acceptance/closure. | Ensures accountability and provides a clear, quantifiable record of improvement results. |

| Lack of Motivation (Reliance on mandatory KPIs) | “Points Mall” Incentive System | Employee effort in lean activities is automatically converted into points, with system-generated individual and team rankings. Points can be redeemed for prizes. | Turns lean management into a gamified, self-driven activity, ensuring sustained participation. |

Other Key Applications

The success of the initial projects led to rapid expansion across the Group, with 10+ member enterprises adopting the platform.

Other critical applications include:

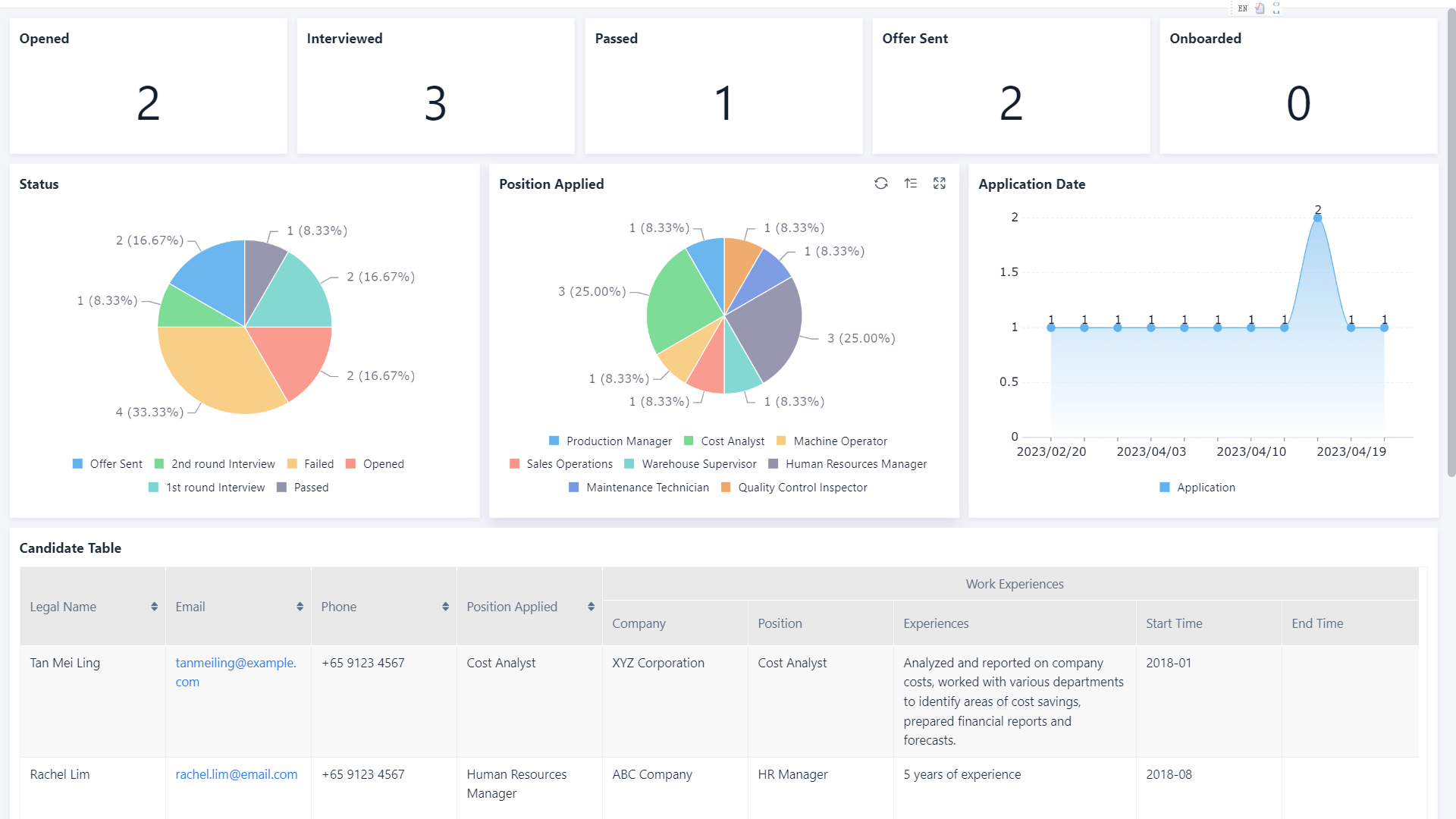

- HRIS Platforms: Full-process online HR management, streamlining workflows and increasing employee involvement.

“The system automated the entire HR process, improving our efficiency by approximately 100%,” says Ms. Jiang Xia, a Customer Service Manager at Er-Yao, who now uses the system for sales order management. “More importantly, it broke the management silo. User departments’ participation in employee management increased by 70%, as they could now directly approve promotions, training, and view team performance data in real-time.“

- Engineering Project Reports: Utilizing Jodoo’s data flow and customized view features to integrate contract and project information, providing a unified, visual management dashboard for complex, multi-million dollar construction projects.

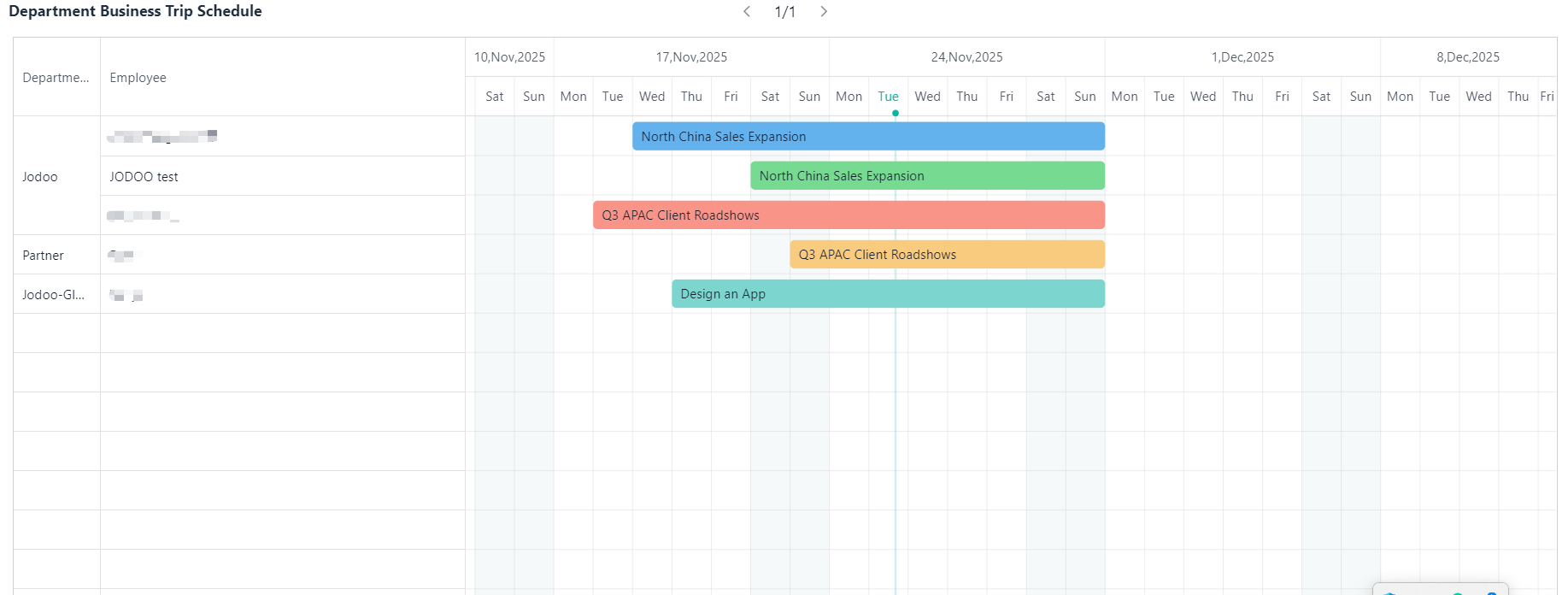

- Department Business Trip Dashboard: A simple, yet essential, application that provides managers with real-time visibility into their team’s location and schedule, improving coordination and sales management.

The Results: Quantifiable ROI and a 70% Surge in Engagement

The implementation of Jodoo delivered immediate, quantifiable results that demonstrated a rapid return on investment (ROI) and validated Fosun Pharma’s strategic pivot. The ROI was measured in weeks, not years.

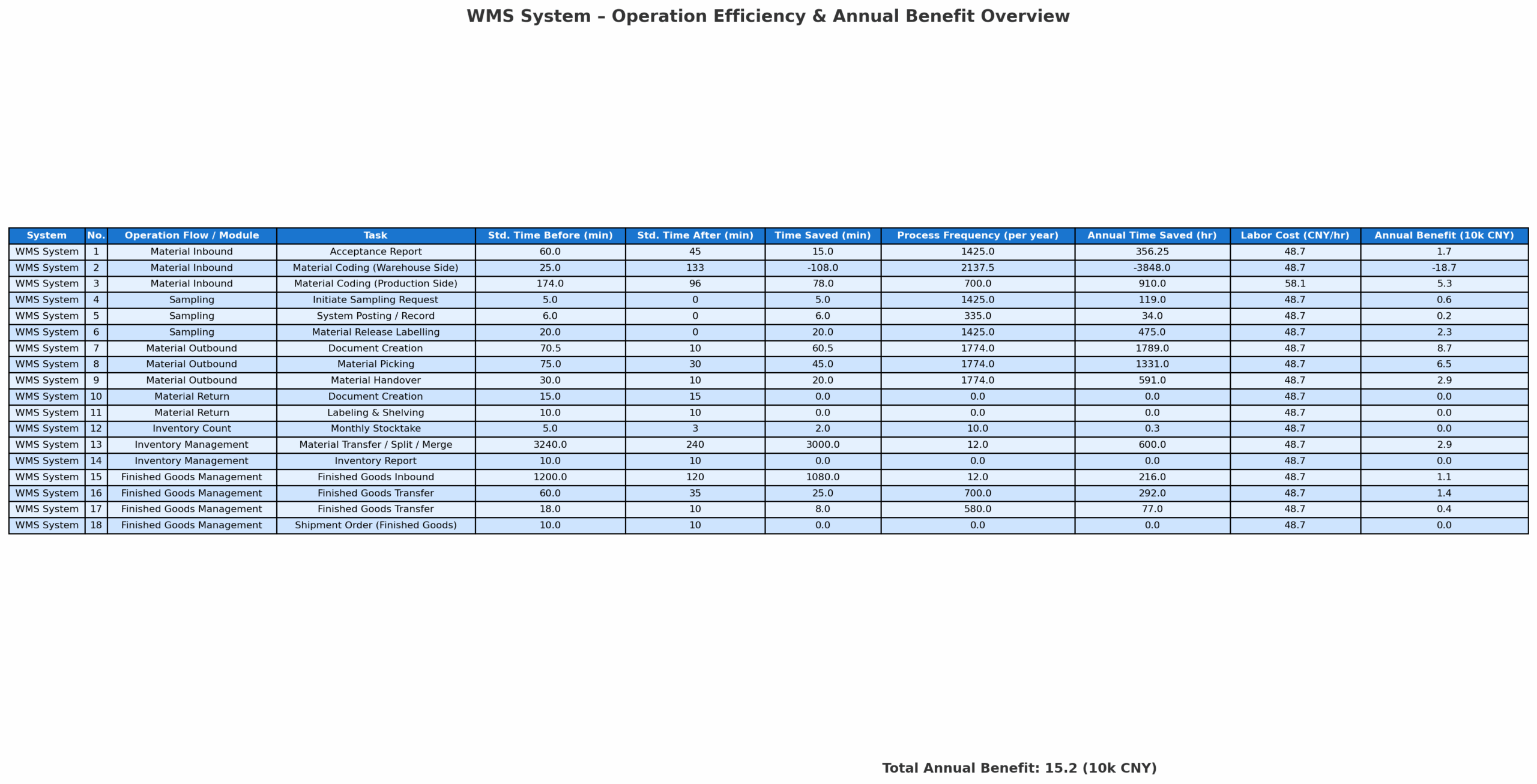

Dramatic Time and Cost Savings

The most dramatic result was the transformation of the Quality Monthly Report process:

| Key Performance Indicator | Before Jodoo | After Jodoo | Improvement |

|---|---|---|---|

| Critical Report Cycle Time | 2-3 Weeks | 5 Minutes | 99.9% Reduction |

| HR Process Efficiency | Manual | Online | Automated |

| Employee Management Participation | 16% | 86% | 70% Increase |

“If we can save 2.8 million USD every year through lean improvements, then spending $280,000 USD on a system is not a problem, because the return is high enough.“

— A User from the Lean Management Department

In fact, ERYE Pharmaceutical, a subsidiary, achieved nearly $4.2 million in value within a single year through its lean management initiatives built on Jodoo.

A Culture of Autonomy and Empowerment

Beyond the hard numbers, the platform fostered a profound cultural shift. The increase in departmental participation in employee management by 70% is a direct result of the transparent, accessible tools provided by the Lean Management Ecosystem. Frontline staff, now equipped with the “Golden Idea” submission tool, feel empowered to contribute, shifting the organisation from being led by a single department to being governed collaboratively by all employees.

The Future Outlook: Truly Taking Control of Our Digital Destiny

Fosun Pharma’s journey with no-code development is a powerful testament to the value of business autonomy in the digital age. With 28,187 users actively engaged on Jodoo, the initial success is now being scaled across the entire network of member enterprises by establishing a comprehensive knowledge base for applications and hosting internal webinars to facilitate knowledge sharing.

The Group’s leadership now views the no-code platform as the key to achieving a sustainable, scalable digital ecosystem. Mr. Lin, President’s Assistant and Chief Digital Officer (CDO), summarizes the strategic impact:

“The emergence of the no-code development platform has bridged the ‘last mile’ gap between IT and business, granting the simplicity and convenience of application development to the users, while leaving the responsibility of ensuring security and reliability to the IT middle and back office, forming a virtuous ecosystem. This is how we achieve co-governance and shared innovation across the Group.”

Fosun Pharma is no longer just pursuing lean management; it is demonstrating how digital lean is the essential strategy for building a resilient, high-efficiency, and future-proof global pharmaceutical enterprise.

Ready to empower your business users and achieve rapid ROI?

、