50%

Reduction in Manual Data Entry: Streamlined processes eliminated significant manual input, freeing up valuable employee time.

3

Countries with Real-time Data Visibility: Centralized data access enabled immediate insights into operations across all global factories.

80%

Faster Machine Repair Response: Automated repair requests and tracking drastically cut down maintenance times, minimizing production downtime.

“For us in IT and CI, Jodoo‘s form construction is very simple and fast, because the form can be built without code. And we can adjust the form at any time, which is very simple and convenient.”

—Linda, CI Department, Fook Wah Kun Kee Knitting Factory Co., Ltd.

Introduction: FWKK—A Global Leader in Swimwear Manufacturing

FWKK is a powerhouse in producing high-quality swimwear and sports equipment. The company’s enduring success is rooted in its core purpose, encapsulated by the acronym SWIM—Solve the Problem, Win the Heart, Innovate, and Master Our Craft. This commitment to problem-solving, customer trust, continuous innovation, and craftsmanship has positioned FWKK as a trusted supplier in the global market.

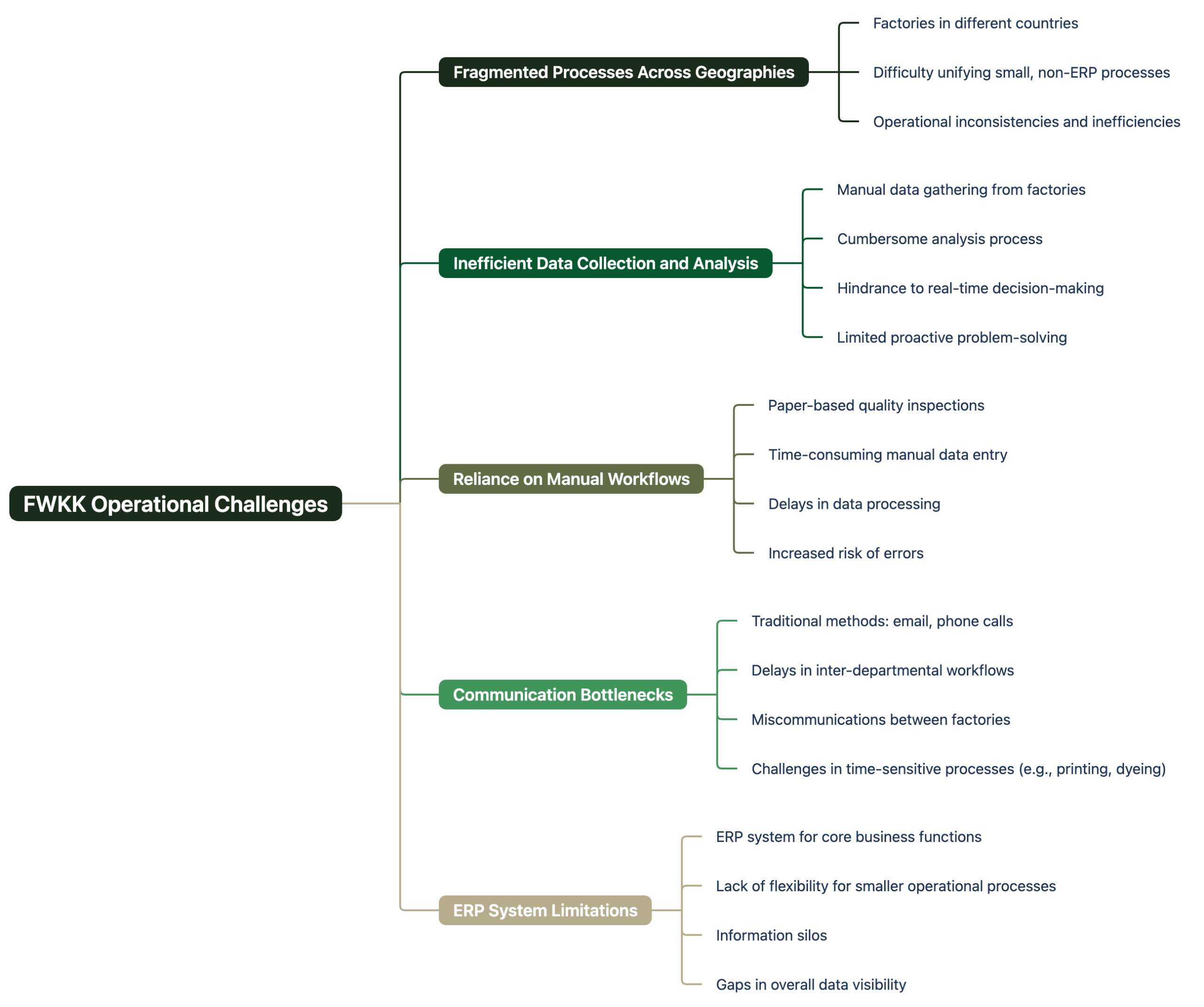

The Challenge: Navigating Complexity in a Global Manufacturing Landscape

Despite its impressive scale and long-standing reputation, FWKK faced significant operational hurdles inherent in managing a vast, multinational manufacturing operation. The primary challenges included:

- Fragmented Processes Across Geographies: With factories in different countries, unifying small, non-ERP processes and standardizing operations proved difficult, leading to inconsistencies and inefficiencies.

- Inefficient Data Collection and Analysis: Gathering and analyzing data from each factory was a cumbersome and manual process, hindering real-time decision-making and proactive problem-solving.

- Reliance on Manual Workflows: Critical processes, such as quality inspections, were heavily reliant on paper-based records, requiring time-consuming manual data entry into computers for later analysis. This created delays and increased the risk of errors.

- Communication Bottlenecks: Traditional communication methods, like email and phone calls, often lead to delays and miscommunications in inter-departmental and inter-factory workflows, particularly in time-sensitive processes like printing and dyeing.

- ERP System Limitations: While an ERP system was in place for core business functions, it lacked the flexibility to manage smaller, yet crucial, operational processes, creating information silos and gaps in overall data visibility.

These challenges collectively impacted FWKK’s ability to maintain optimal efficiency, ensure consistent quality, and respond swiftly to operational demands across its expansive global network.

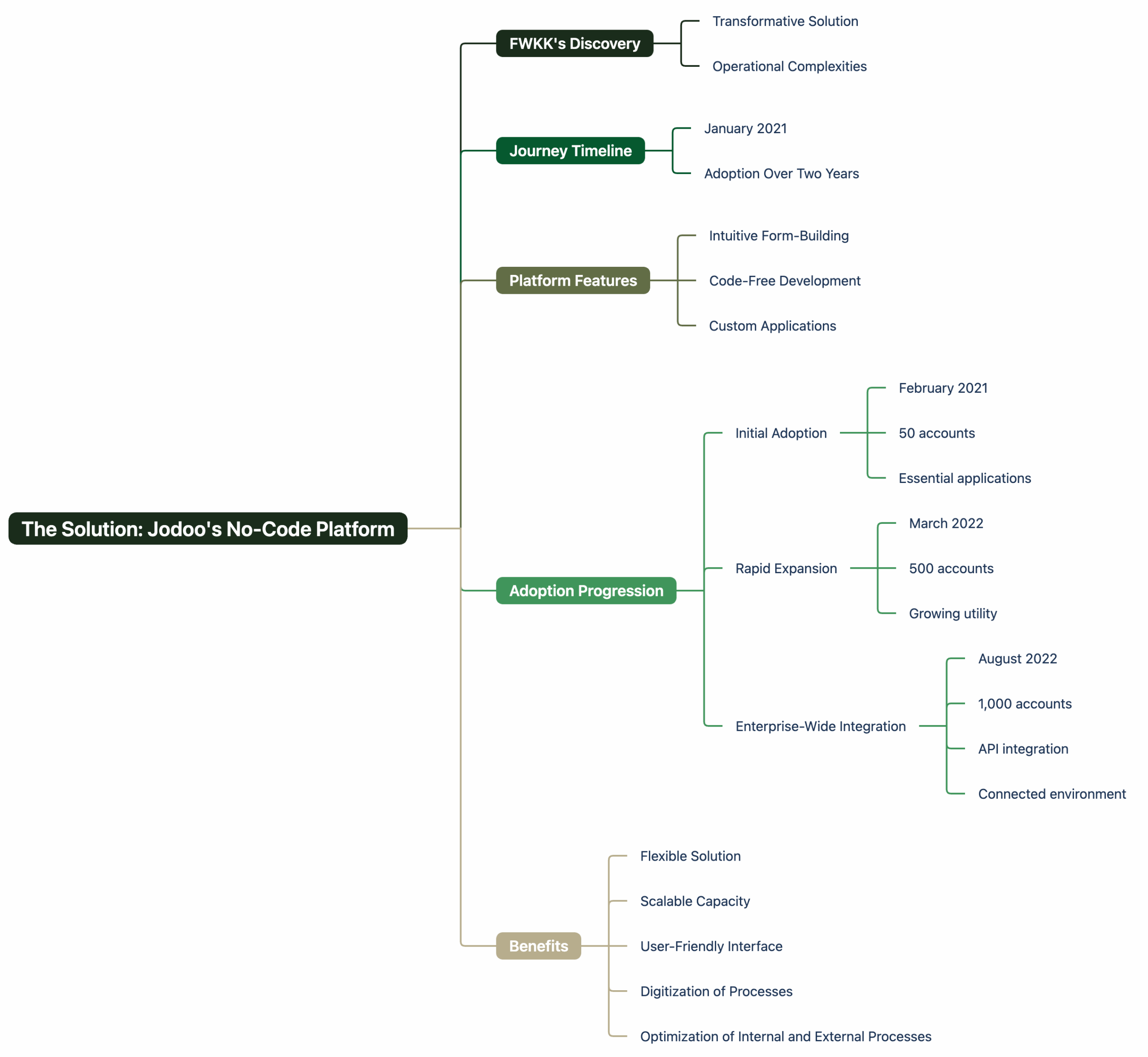

The Solution: Jodoo’s No-Code Platform—A Catalyst for Digital Transformation

FWKK discovered Jodoo’s no-code platform as a transformative solution to its operational complexities. The journey began in January 2021, and within two years, Jodoo became an integral part of FWKK’s digital ecosystem. The platform’s intuitive, code-free form-building capabilities allowed FWKK to rapidly develop and deploy custom applications, addressing specific pain points that their existing ERP system could not.

The adoption of Jodoo progressed steadily:

- Initial Adoption: Starting with 50 accounts in February 2021, FWKK began building essential application modules.

- Rapid Expansion: By March 2022, the number of accounts had increased to 500, reflecting the growing utility and acceptance of the platform.

- Enterprise-Wide Integration: In August 2022, FWKK upgraded to the enterprise version with 1,000 accounts, enabling API integration to combine Jodoo’s data with their existing systems, fostering a truly connected environment.

This rapid adoption underscored Jodoo’s ability to provide a flexible, scalable, and user-friendly solution that empowered FWKK to digitize and optimize a wide array of internal and external processes.

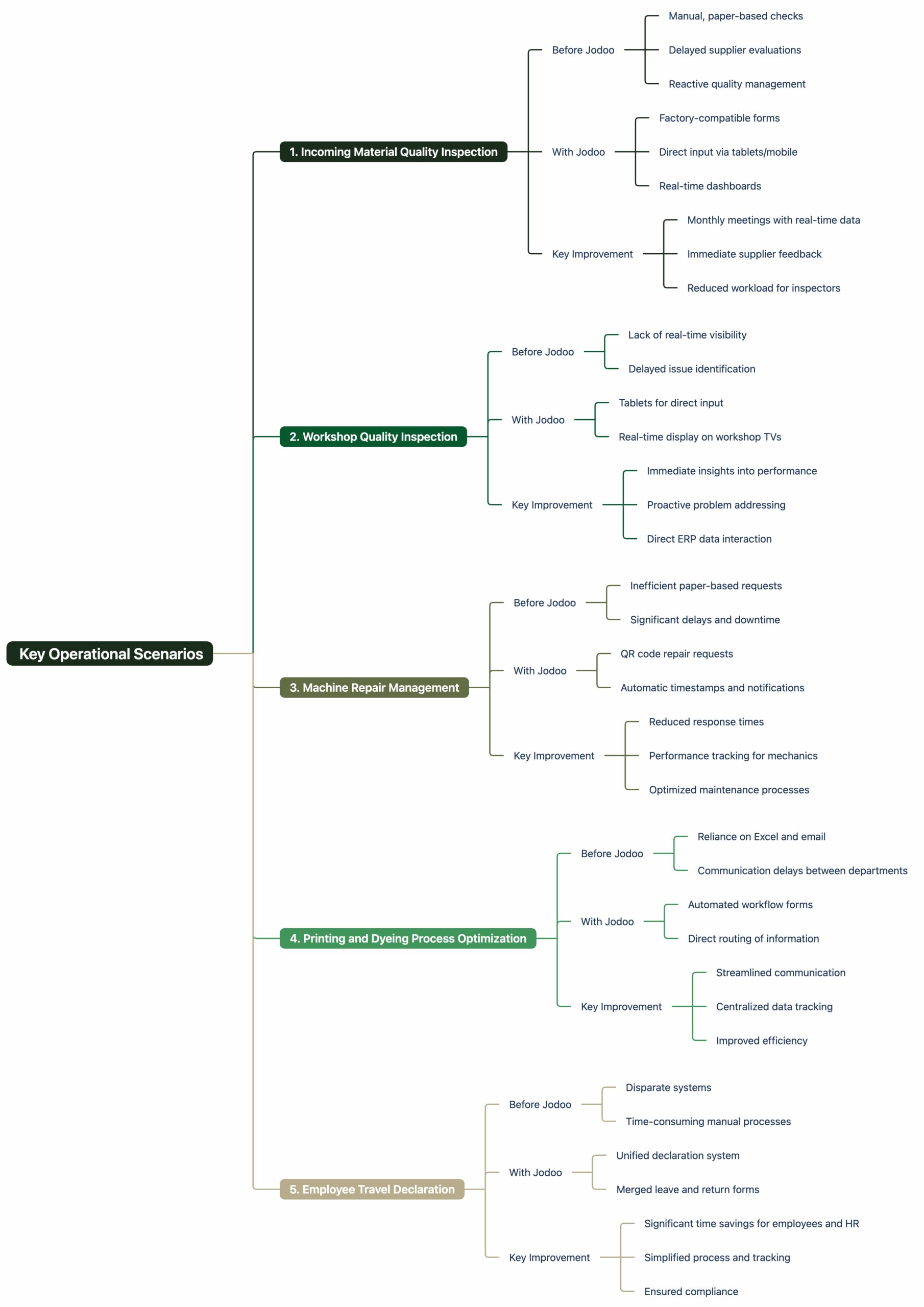

Jodoo in Action: Transforming Key Operational Scenarios

FWKK leveraged Jodoo across five critical operational scenarios, demonstrating the platform’s versatility and impact:

Incoming Material Quality Inspection

Before Jodoo: Manual, paper-based quality checks for incoming materials led to delayed supplier evaluations and reactive quality management.

With Jodoo: Jodoo enabled the creation of factory-compatible forms, allowing quality inspectors to input results directly via tablets or mobile phones. Dashboards provided real-time analysis of supplier quality, defective products, and specific defect types.

Key Improvement: Monthly meetings between the Material and Procurement Departments now utilize real-time data from Jodoo, facilitating immediate supplier feedback and continuous quality improvement. The automated data retrieval significantly reduced the workload for quality inspectors and provided instant insights.

Workshop Quality Inspection

Before Jodoo: Lack of real-time visibility into production line quality, leading to delayed identification and resolution of issues.

With Jodoo: Each quality inspector was equipped with a tablet or mobile phone to input quality inspection results directly into Jodoo. Real-time data was displayed on TVs in workshops, showing efficiency and defective product rates.

Key Improvement: This provided immediate insights into production line performance, allowing workshop administrators to identify and address problems proactively. The real-time data eliminated the need for post-production statistics and enabled direct interaction with ERP data for meetings and improvements.

Machine Repair Management

Before Jodoo: Inefficient, paper-based machine repair requests caused significant delays and production downtime.

With Jodoo: FWKK implemented a Jodoo-based system where production personnel could scan a QR code to fill out a repair request form. The system automatically generated timestamps and sent notifications to mechanics via messaging platforms.

Key Improvement: This drastically reduced response times for machine repairs. The system tracked the time from request submission to repair completion, providing valuable data for analyzing mechanic performance and optimizing maintenance processes, thereby minimizing unproductive downtime.

Printing and Dyeing Process Optimization

Before Jodoo: The printing and dyeing process relied on Excel and email for communication, leading to significant delays and inefficiencies between departments.

With Jodoo: A Jodoo form was developed to automate the printing and dyeing workflow. Once the sales department completes and submits the form, it automatically routes to the next department, eliminating manual calls and emails.

Key Improvement: This streamlined inter-departmental communication, allowing employees to track progress directly on the Jodoo platform. It also centralized printing information, making it easier to extract and analyze data, significantly improving efficiency and reducing communication overhead.

Employee Travel Declaration

Before Jodoo: Managing employee travel declarations, especially during the COVID-19 , involved disparate systems and time-consuming manual processes.

With Jodoo: FWKK utilized Jodoo to create a unified system for employee travel declarations, including COVID-19 nucleic-acid test certificates and itinerary codes. Unlike other systems, Jodoo allowed for the merging of information from “leave” and “return”forms into a single, streamlined process.

Key Improvement: This saved significant time for both employees and HR by simplifying the declaration process and centralizing information, ensuring compliance and efficient tracking of employee movements.

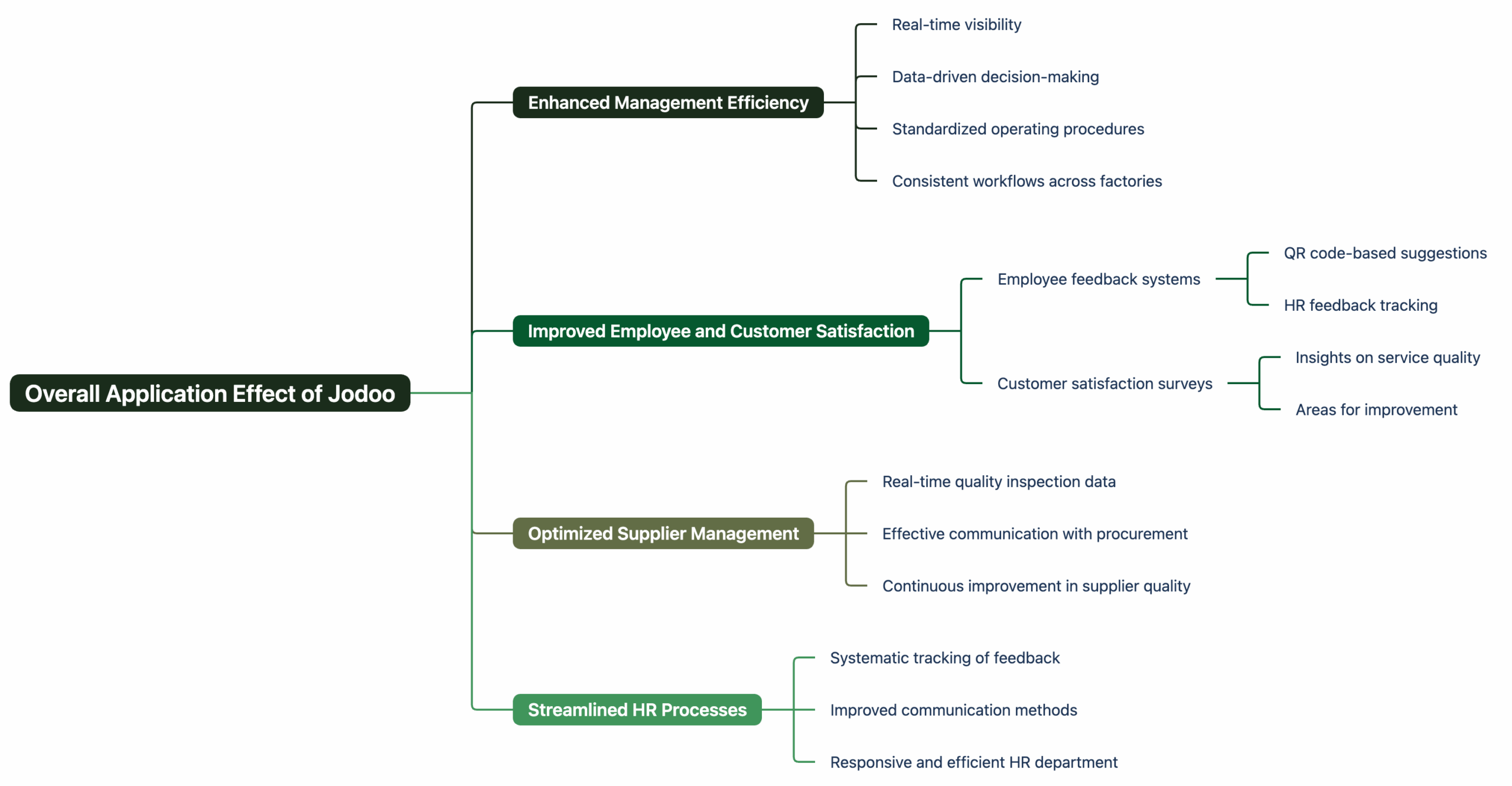

Overall Application Effect of Jodoo

The implementation of Jodoo has brought about a profound transformation in FWKK’s operations, delivering tangible benefits across various levels:

Enhanced Management Efficiency

Jodoo provides managers with real-time visibility into workshop statuses and data anomalies directly from their mobile devices. This immediate access to critical information facilitates data-driven decision-making during meetings and streamlines data collection processes. Furthermore, Jodoo has enabled FWKK to standardize operating procedures across its domestic and international factories, ensuring that all employees follow consistent workflows and operational methods.

Improved Employee and Customer Satisfaction

FWKK has leveraged Jodoo to implement robust feedback systems. For employees, a QR code-based suggestion system allows them to provide input on work and life, track HR’s feedback, and confirm satisfaction with resolutions. This continuous feedback loop has significantly improved employee satisfaction. Similarly, Jodoo facilitates customer satisfaction surveys, enabling FWKK to gather valuable insights into service quality, delivery times, and areas for improvement, ensuring that customer needs are met and expectations are exceeded.

Optimized Supplier Management

With real-time analysis of incoming material quality inspection data, FWKK can now communicate more effectively with procurement and suppliers. This immediate feedback mechanism allows for continuous improvement in supplier quality, strengthening the supply chain and ensuring the consistent quality of raw materials.

Streamlined HR Processes

The HR management system has been significantly perfected. Previously, communication and opinion exchange relied on paper-based methods, often lacking proper follow-up or feedback. Now, with Jodoo, employees’ suggestions are systematically tracked, ensuring that feedback is addressed and actions are taken, leading to a more responsive and efficient HR department.

Future Applications: A Continuous Journey of Digital Innovation

FWKK’s journey with Jodoo is far from over. The company envisions a future where Jodoo continues to play a pivotal role in its digital transformation. Key areas for future application include:

- Enhanced API Integration: Further integration between Jodoo and existing ERP systems to create a more seamless and interconnected data environment.

- Expanded Data Combination Capabilities: Leveraging Jodoo’s flexibility to combine data from various sources for deeper insights and more comprehensive analysis.

- Reduced Manual Labor Costs: Continued automation of processes to further minimize manual effort and optimize operational costs.

- Improved Work Efficiency: Driving greater efficiency through continuous system integration and process refinement.

- Development of Specialized Modules: Creating more specialized modules tailored to specific manufacturing processes, further enhancing operational control and optimization.

FWKK’s experience with Jodoo exemplifies how a no-code platform can empower large-scale manufacturing enterprises to overcome complex operational challenges, foster internal and external collaboration, and achieve significant advancements in efficiency, quality, and stakeholder satisfaction. The partnership between FWKK and Jodoo is a testament to the power of digital innovation in shaping the future of manufacturing.

Ready to transform your collaborations and empower your teams with no-code innovation? Discover how Jodoo can help your business achieve similar success.