$140,000

Saved in System Development/Maintenance Cost

99.8%

Hazard Rectification Rate

95%

Time Reduction in PTW Approval Time

Goldwind is a giant in the world of clean energy. As a global leader in wind power, they are on a mission to make sustainable energy affordable, reliable, and accessible to everyone. With operations spanning six continents and 29 countries, Goldwind is a key player in the global transition to a greener future. They are consistently ranked among the world’s most innovative and environmentally friendly companies.

But being a leader means never standing still. For Goldwind, this means a relentless focus on safety. In the high-stakes world of wind energy, where teams work in challenging environments and manage complex machinery, safety is not just a priority—it’s the foundation of everything they do. As the company grew, they realized that their old, paper-based safety management systems were not keeping up. They needed a smarter, faster, and more connected way to keep their people safe. This is the story of how a team of safety managers, with no background in IT, used a no-code platform to build a world-class digital safety system from the ground up.

The Challenge: Managing Safety at a Global Scale

For a company as large and widespread as Goldwind, managing safety is a huge and complex job. The wind energy business involves big machines, remote locations, and dangerous tasks. A small mistake can lead to a serious accident. Goldwind has always been committed to safety, but as the company grew, the team found that their old ways of doing things were creating dangerous blind spots.

They faced four major challenges in their Environmental, Health, and Safety (EHS) management process:

- A Lack of Real-Time Information: Managers couldn’t get a clear, up-to-the-minute picture of what was happening on the ground. Safety data was collected on paper and then manually entered into spreadsheets. This process was slow and full of errors. By the time managers saw the reports, the information was already old. This made it impossible to spot problems early and prevent accidents before they happened.

- Low Employee Involvement: Safety is everyone’s job, but Goldwind’s old system didn’t make it easy for employees to get involved. The process for identifying and reporting risks was complicated and time-consuming. As a result, most employees were not actively participating. The responsibility for safety fell entirely on the shoulders of a few managers, which was not effective or sustainable.

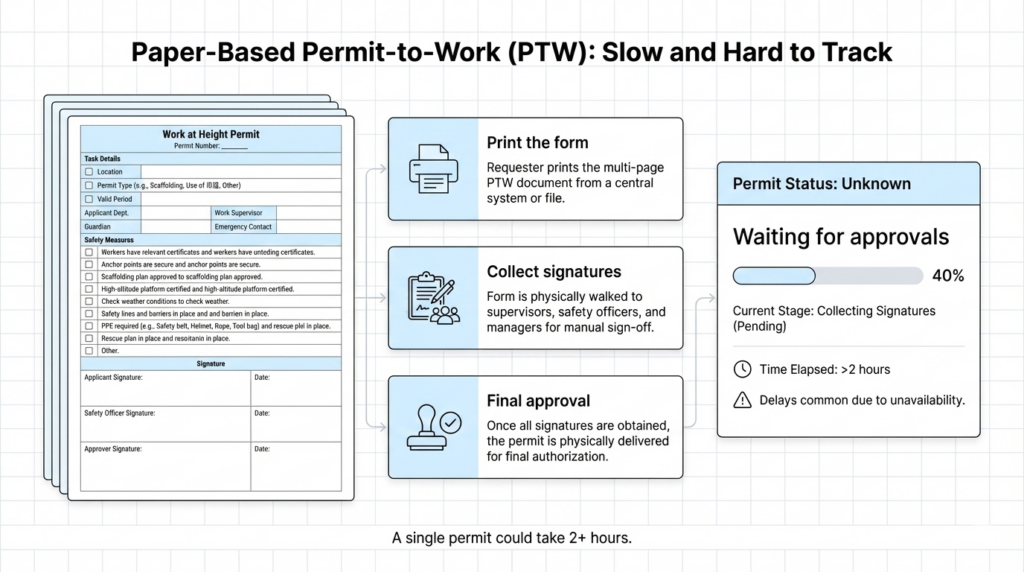

- Inefficient and Risky Permit-to-Work (PTW) System: For any dangerous job, like working at heights or with high-voltage electricity, a special work permit is required. At Goldwind, this was a completely manual, paper-based process. An employee had to print a form, run around to get signatures, and then get final approval. A single permit could take over two hours to process. This was not only inefficient, but it was also risky. It was hard to track the status of permits, and there was no easy way to ensure that all safety checks had been completed.

- Inconsistent Contractor Management: Goldwind works with over 100 different contracting companies for everything from maintenance to construction. Each of these companies had its own way of doing things, and their safety standards were not always up to Goldwind’s high expectations. Managing these contractors was a huge challenge. It was difficult to track their training, monitor their performance, and ensure they were following Goldwind’s safety rules. This created a major source of risk for the company.

Goldwind knew they needed a change. They needed a single, unified system that could connect everyone—from the frontline workers to the senior executives—and give them the tools and information they needed to work safely and efficiently.

The Solution: A Digital Safety Platform Built by Safety Experts

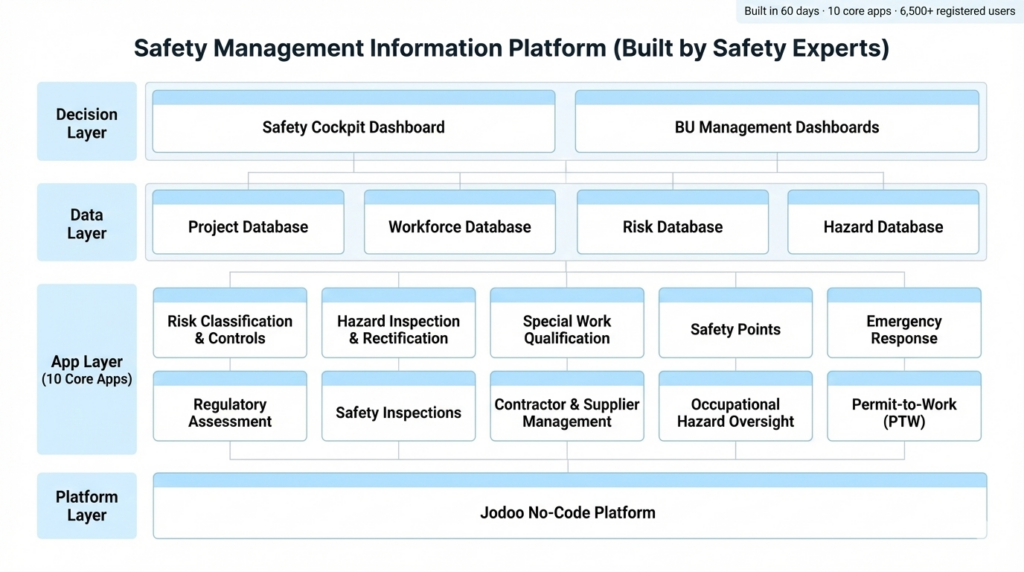

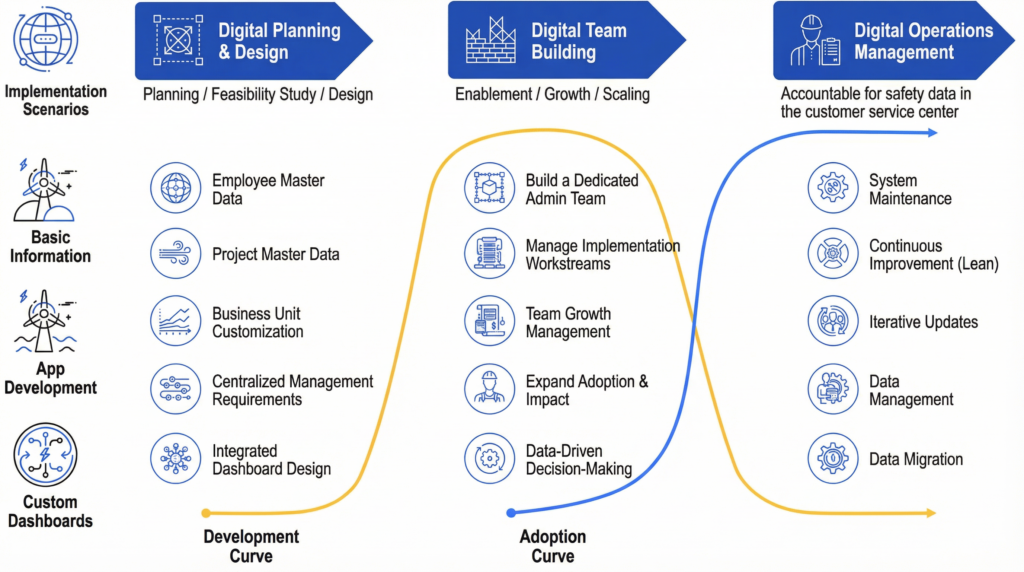

Instead of hiring a team of expensive consultants or launching a massive IT project, Goldwind took a different approach. They put the power to build a solution directly into the hands of the people who understood the problem best: their own safety managers.

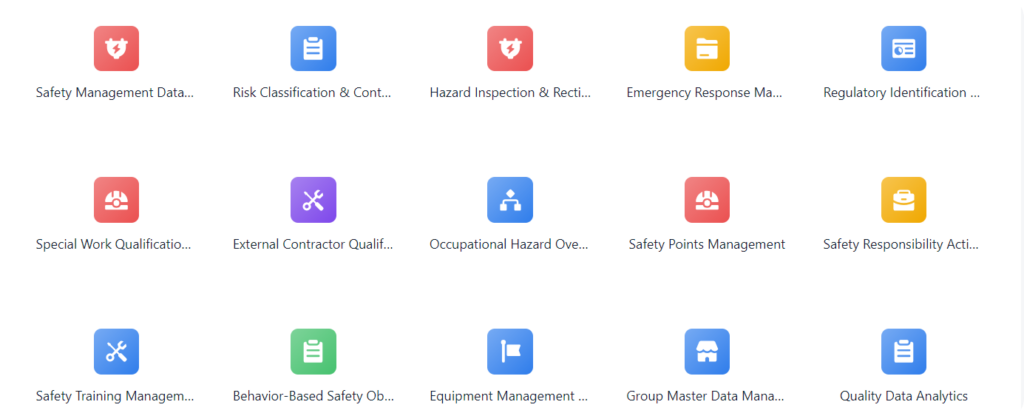

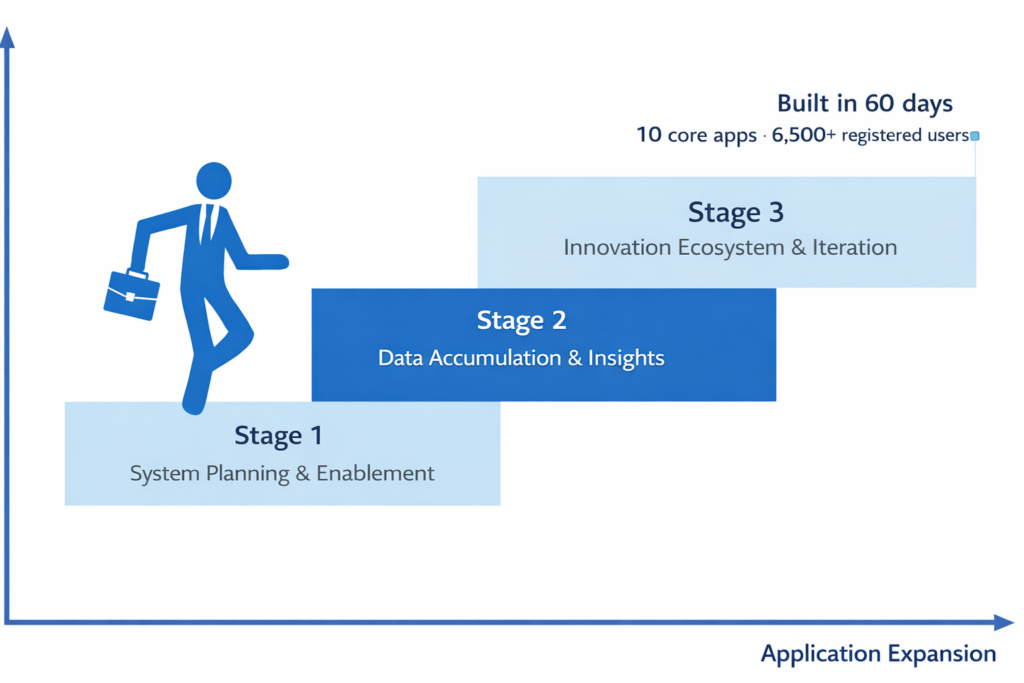

This team of safety experts, with no formal IT training, used the Jodoo no-code platform to design and build a comprehensive “Safety Management Information Platform.” In just 60 days, they had a working system up and running. Today, that system has grown to include 10 major apps that are used by over 6,500 employees and contractors every day.

Here’s how they tackled their biggest challenges:

A Real-Time View of Safety with a “Safety Cockpit”

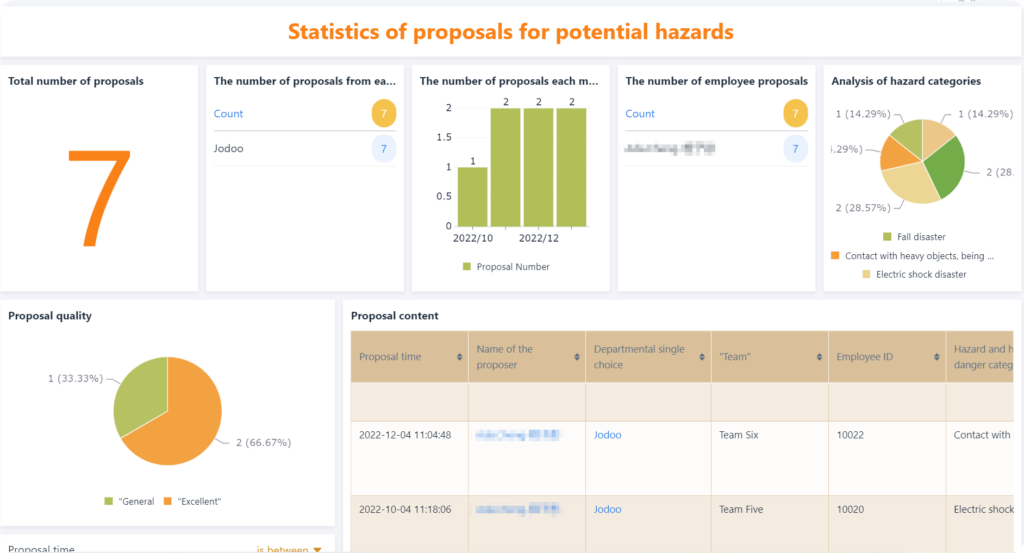

To solve the problem of outdated information, the team built a “Safety Management Cockpit” using Jodoo’s dashboard feature. This central dashboard provides a live, visual overview of safety performance across the entire company. Managers can see everything at a glance: the number of open safety issues, the status of work permits, and the safety performance of different teams and contractors. This real-time visibility allows them to spot trends, identify high-risk areas, and make smarter, data-driven decisions to improve safety:

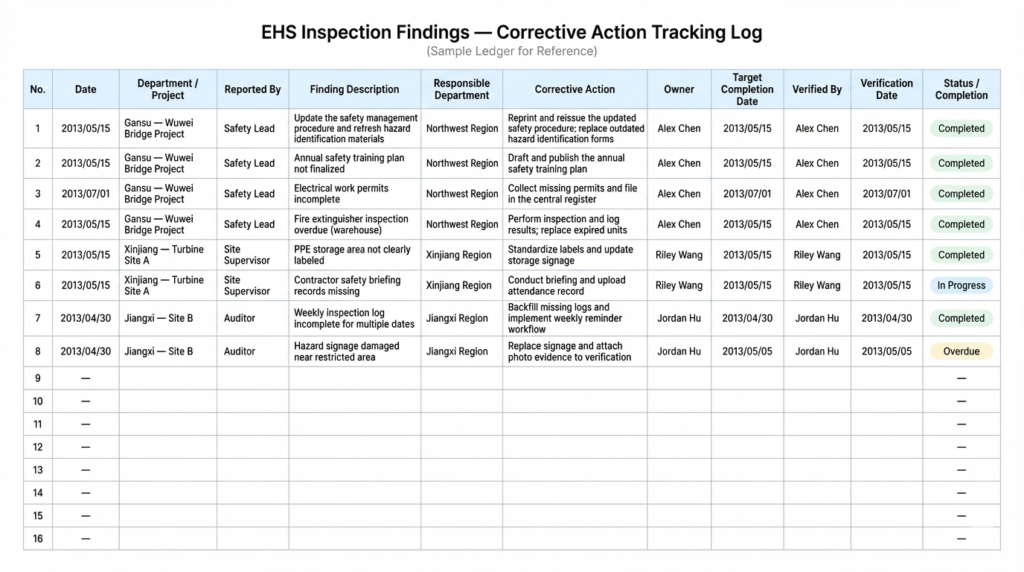

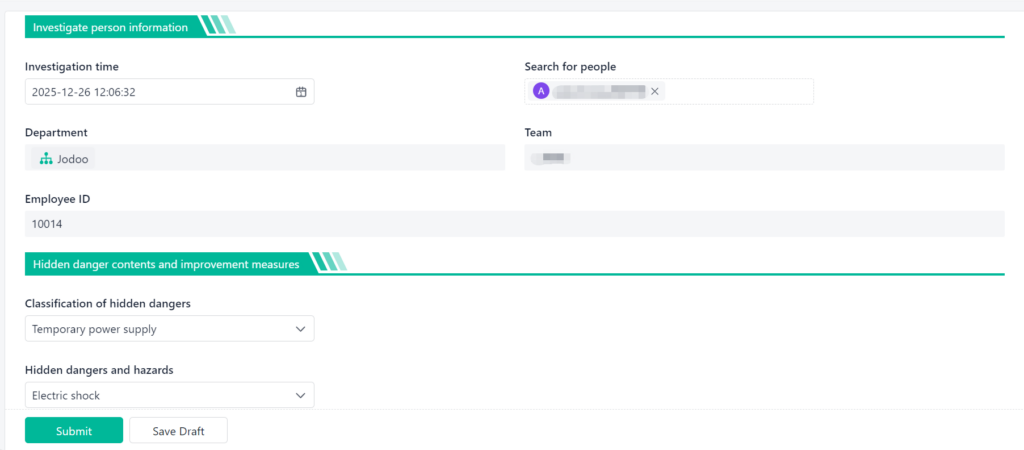

- Mobile Reporting: The system includes forms for “Hazard Reporting Platform,” “Daily Safety and Environment Inspection,” and “Special Safety Inspections.” This allows any employee to use their mobile device to instantly report a hazard, including photos and location data.

- Automated Analysis and Dashboard: The system uses Jodoo’s Data Factory to convert reported addresses into a “Data Map” and automatically calculates and analyzes key metrics like “Hazard Reporting Rate” and “Hazard Rectification Rate.” This provides managers with a real-time, visual overview of the safety status.

- High Closure Rate: The system’s process-oriented management approach ensures that hazard investigation, rectification, follow-up review, and archiving are strictly controlled, forming an effective closed loop. This has resulted in the accumulation of over 100,000 hazard data records and a remarkable 99.8% hazard rectification rate.

Empowering Every Employee to Be a Safety Leader

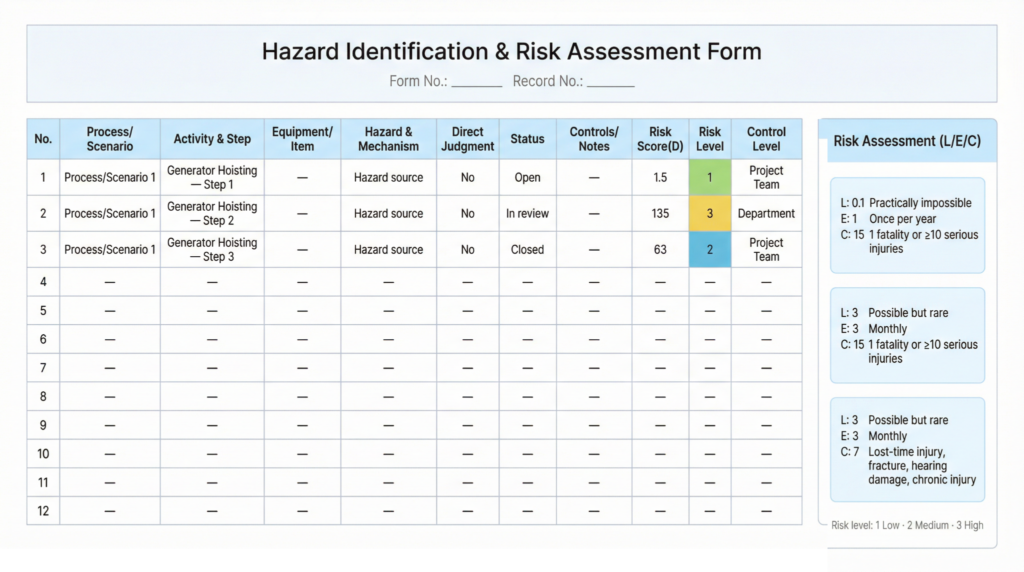

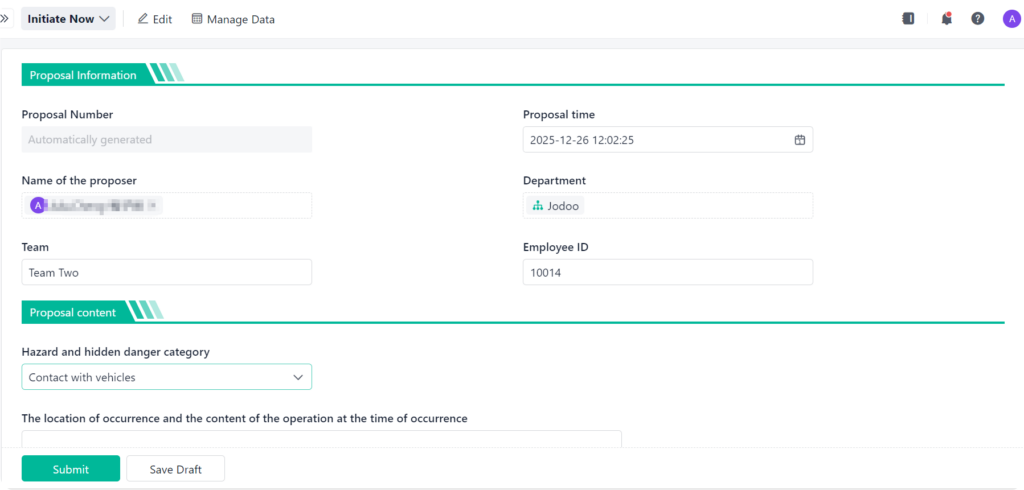

The team created a simple, mobile-friendly app for “Risk Identification and Assessment.” The team divided the site’s main work into four business processes: General, Construction, O&M, and PV/Substation Services. They identified 22 categories, 181 risk points, and 609 hazard sources.

Now, any employee can use their phone to report a potential hazard as soon as they see it. They can take a picture, add a description, and the information is instantly sent to the right person to be addressed. This has dramatically increased employee participation in the safety program. The system also includes a “Safety Performance Evaluation” module, which tracks each employee’s contribution to safety and creates a culture of accountability and continuous improvement.

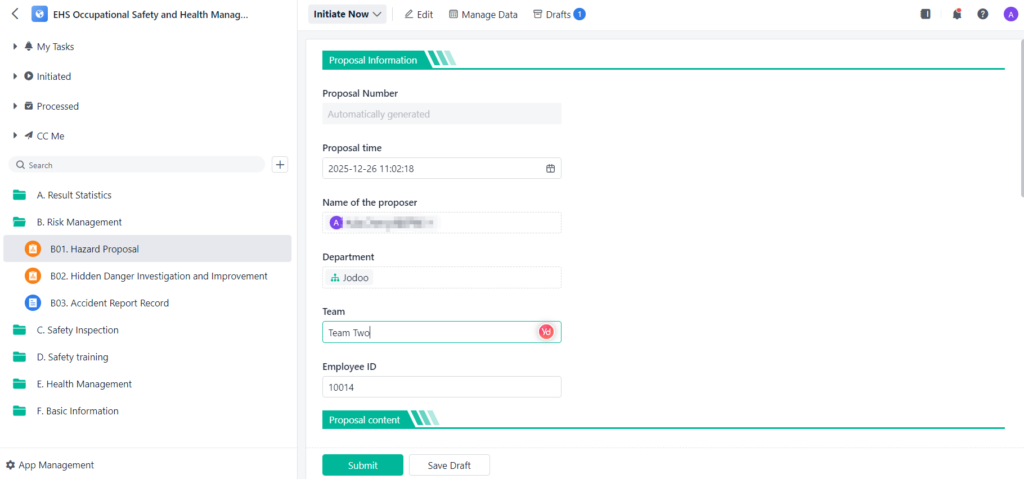

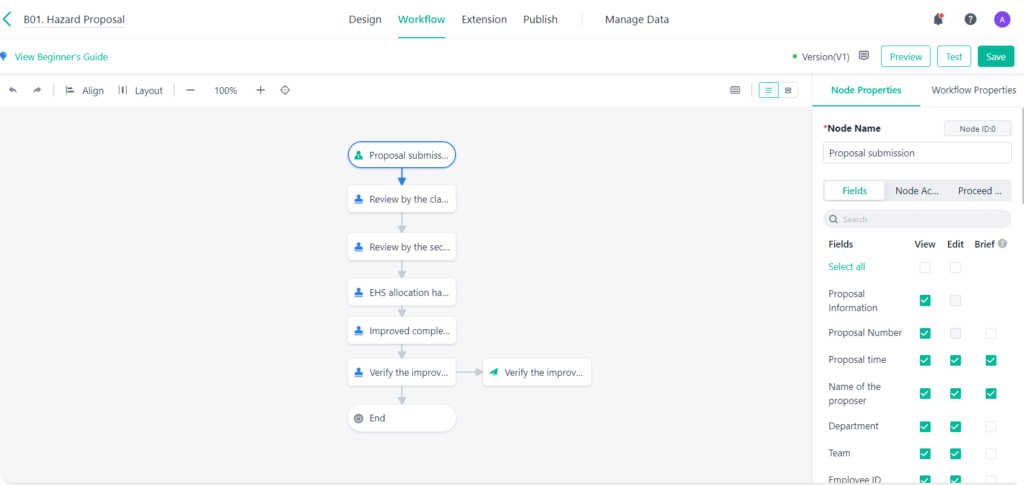

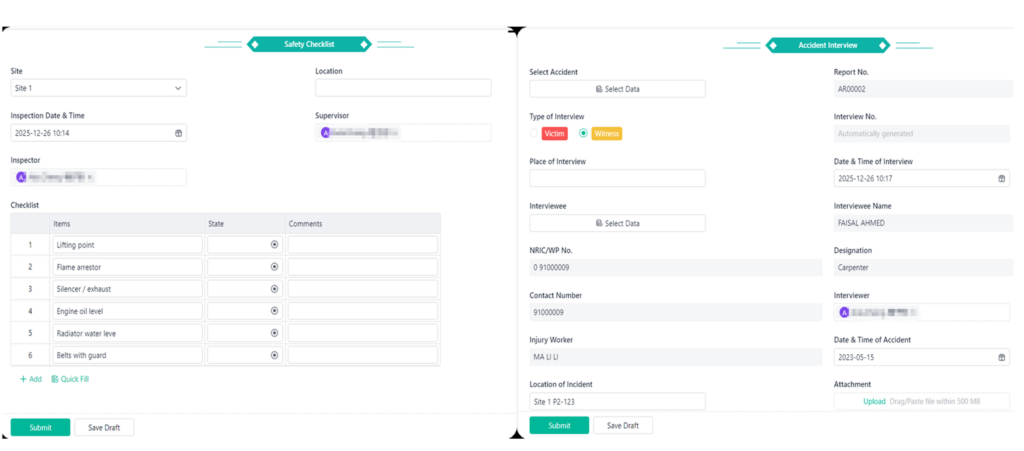

From Paper Permits to Digital Permit-to-Work (PTW) Workflows

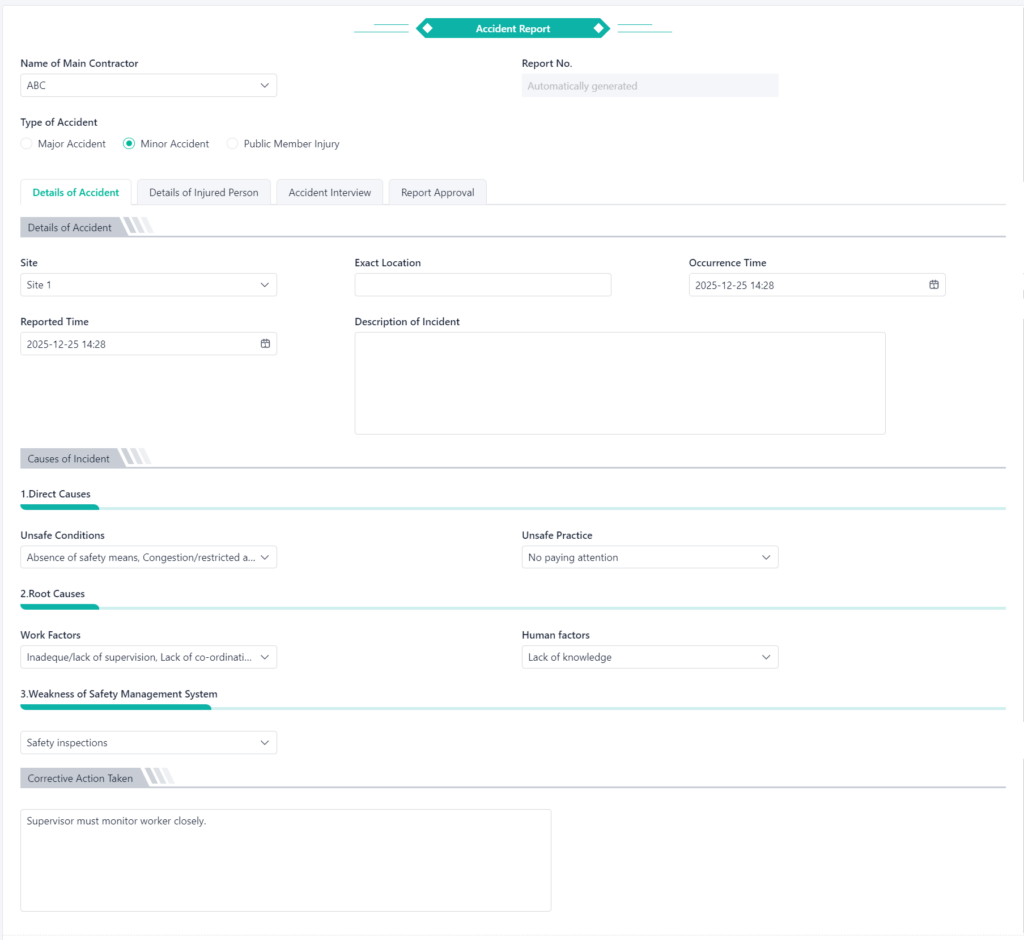

The slow and risky paper-based permit system was replaced with a fully digital Work Permit (PTW) app.

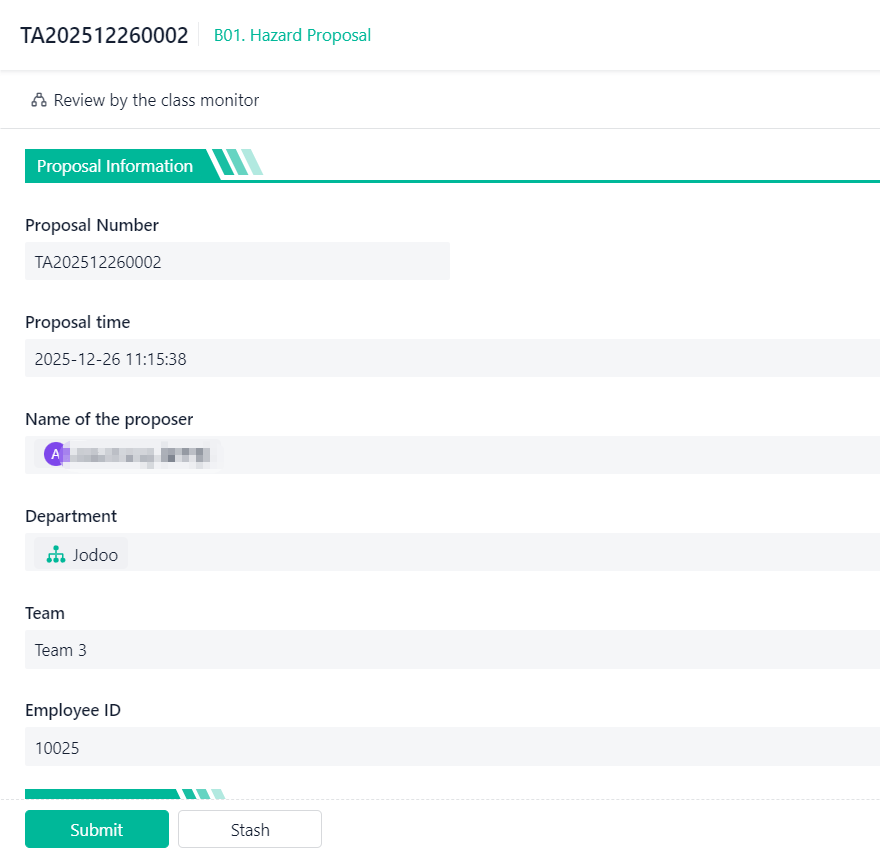

- Digital Workflow: The system digitized the entire PTW process, including seven major permit types (e.g., hoisting, working at height, electrical work). The workflow allows the construction personnel to initiate the request, and all levels of approvers sign off electronically. Now, an employee can request a permit from their phone in just a few minutes.

- Time Reduction: The system uses a “to-do” reminder function to prompt approvers. The request is automatically routed to the right people for approval, and the entire process is tracked in real-time. What used to take over two hours now takes just 3-5 minutes, a massive improvement in efficiency and a huge reduction in risk.

- Centralized Control: The approved permit is instantly generated on-site, providing a clear, traceable record for all high-risk operations. The system ensures that all necessary safety checks are completed before any work begins, effectively controlling operational risk and enforcing accountability.

A Unified System for Contractor Management

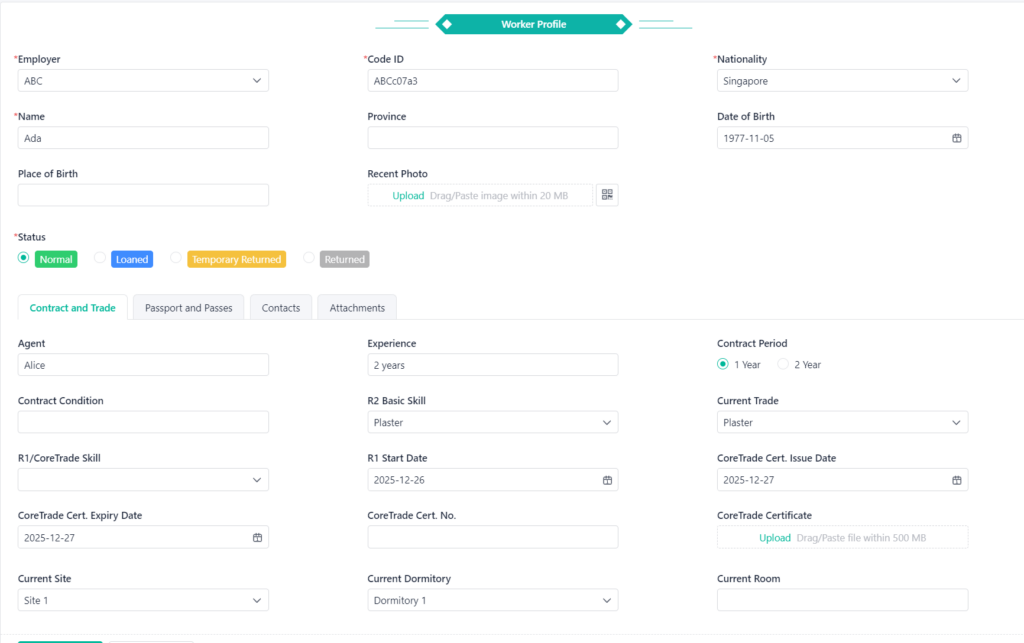

To manage their 100+ contractors, the team built a dedicated “Contractor Management” module. Before any contractor can start work, they must be registered in the system. Goldwind uses the platform to deliver online safety training and track completion:

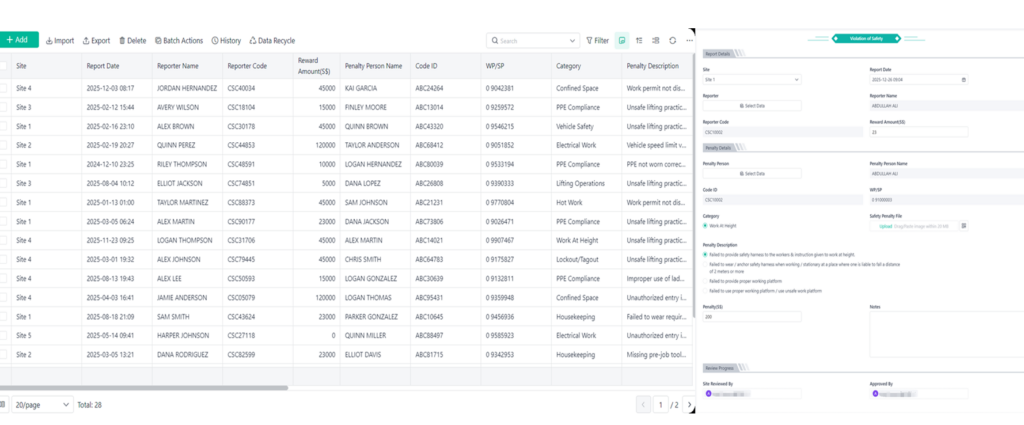

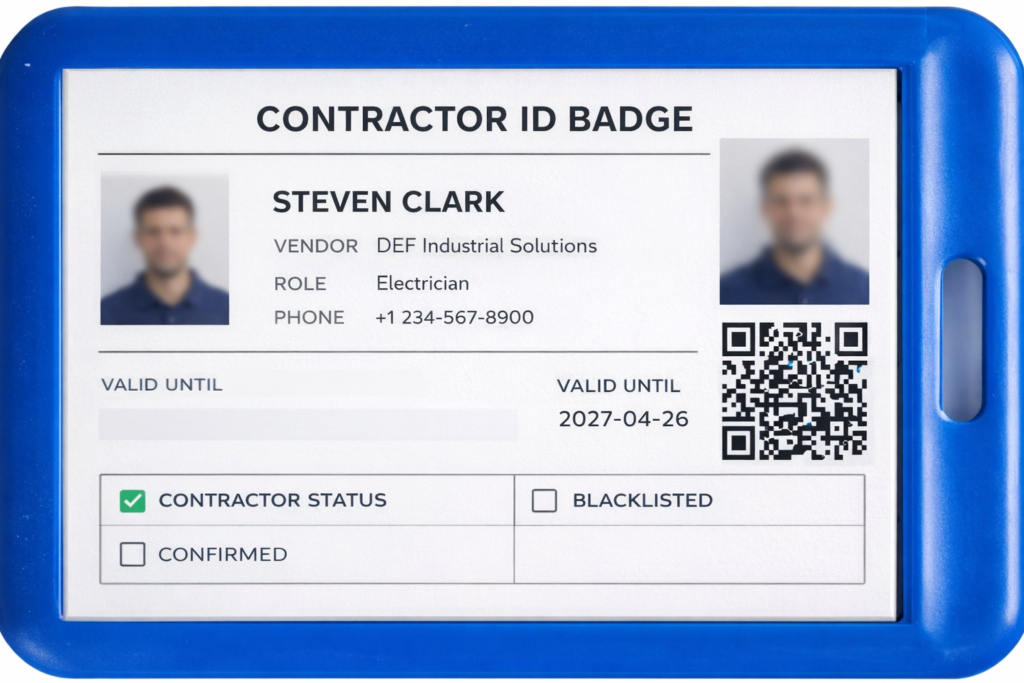

- On-Site Behavior Tracking: The system uses Jodoo’s printing function to generate a standardized ID badge for external employees with a single click. Each contractor employee is issued a digital ID card with a QR code. Safety managers can scan the code to see the worker’s training records and safety performance history. The system also includes a “blacklist” feature, which prevents contractors with a poor safety record from working on Goldwind sites.

- Safety Management Dashboard: A dedicated dashboard provides a quick view of the contractor’s safety assessment results and violation records, enabling Goldwind to provide professional risk assessment and safety inspection services. This has created a single, standardized system for managing contractor safety and has significantly raised the bar for all of Goldwind’s partners.

The Results: A Safer, More Efficient, and More Engaged Workforce

The impact of Goldwind’s new digital safety platform has been remarkable. By empowering their safety team to build their own solutions, the company has not only improved safety but also saved a significant amount of time and money. The numbers tell a clear story of success.

| Key Performance Indicator | Before Jodoo | After Jodoo |

|---|---|---|

| System Development & Maintenance Costs | High, reliant on external vendors | Saved $140,000 |

| Hazard Rectification Rate | Low, difficult to track | 99.8% |

| Hazardous Work Permit Approval Time | Over 2 hours | 3-5 minutes |

| Safety Information Flow Efficiency | Slow, paper-based (up to 1 week) | Real-time, digital |

| Hazard Data Records | Limited, fragmented | Over 100,000 records |

By building the system in-house with Jodoo, Goldwind estimates that they have saved over $140,000 in development and maintenance costs. The 30% improvement in information flow efficiency means that problems are identified and resolved faster than ever before. The reduction in permit approval time from over two hours to just a few minutes has been a game-changer for operational efficiency.

But the most important results are not just about time and money. The platform has created a true safety culture at Goldwind. With over 800 people using the system every day, safety is no longer the responsibility of a few managers; it’s a shared responsibility for everyone. The platform has given every employee the tools and the voice to be a safety leader.

Future Outlook: A Data-Driven Future for Clean Energy

For Goldwind, the journey to a safer future is just beginning. The success of the Safety Management Information Platform has shown the entire company the power of data and the potential of no-code tools. Their vision is to create a fully integrated digital ecosystem where data from every part of the business is used to make smarter, faster, and safer decisions.

As one of the project leaders said, “We will use the Jodoo no-code development platform to break down the safety management barriers of the entire group, share and analyze various individual and common problems, and avoid the risk of different entities having accidents on the same issue. We will establish a business-level, data-level, and platform-level process concept. This will make the safety decision-making of the wind power industry group more scientific and data-driven, improve safety management efficiency, and ensure that risks are discovered and effectively controlled in a timely manner, so as to reduce and eliminate safety accidents.”

Goldwind’s story is a powerful lesson for any large enterprise. It shows that digital transformation doesn’t have to be a slow, expensive, and top-down process. By empowering the people who are closest to the problems with the right tools, any company can unlock a new level of innovation, efficiency, and performance. Goldwind is not just building a safer company; they are building a model for the future of the clean energy industry.

Ready to build a safer, smarter, and more connected future for your business?