84.2%

Reduction in Material Waste

65%

Reduction in Obsolete Stock Value

8

Non-IT developers, 10+ apps in 6 months

KE ELECTRIC is a leader in the power system equipment industry. Their high-end electrical switchgear, made by their Brand Cabinet Division, powers major global projects, including venues for the 2022 Winter Olympics. With a deep commitment to technological advancement, KE ELECTRIC continuously seeks to innovate not only its products but also its management systems.

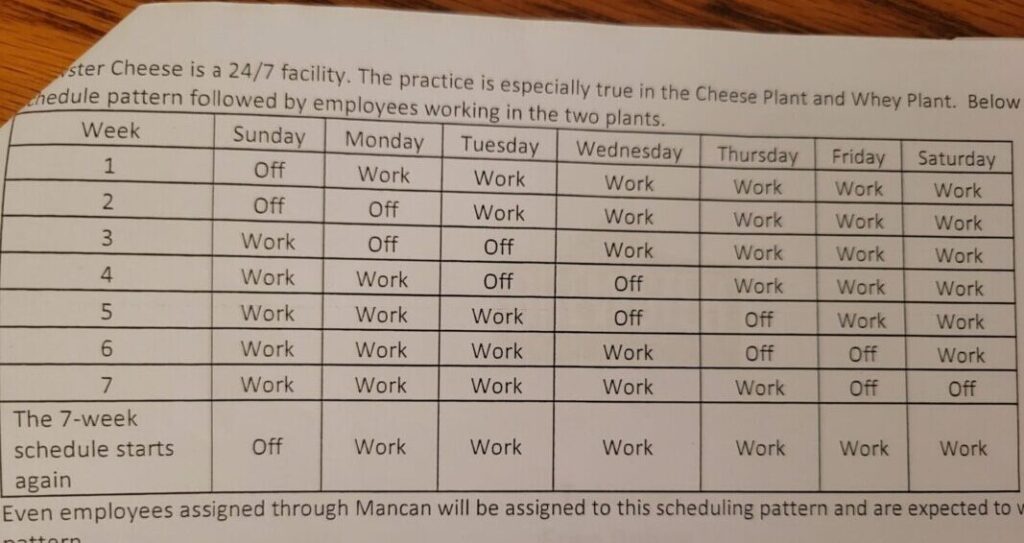

The Brand Cabinet Division, which designs and builds this high-end switchgear, knew it needed to digitalize its operations to stay competitive and achieve its goal of a smart, efficient factory. However, their process was being held back by old, manual methods. A single switchgear takes 10 to 15 days to build.

This is the story of how their team, without a single IT engineer, led a digital change from the factory floor up, turning their operational data into their most valuable asset.

The Challenge: A Disconnected Factory Floor in the Digital Age

The main problems were a lack of real-time data visibility, inefficient resource management, and a high risk of material waste.

The Bottleneck of Manual Work Reporting and Scheduling

The most immediate pain point was the work reporting process. Employees’ work volume was recorded on paper, passed from team leaders to workshop directors, and then to managers for multi-person approval. This paper-based, multi-layered system created significant administrative overhead:

The most critical pain point centered on Quality and Device Monthly Reporting. As a pharmaceutical company, quality is the absolute red line, and the Group requires strict, timely data from its numerous member enterprises.

- Paperwork Nightmare: Workers recorded their hours on paper. This paper then went through many people—team leaders, directors, and managers—for approval. This paper-based system created huge administrative costs:

- Hard to Calculate Pay: As the amount of data grew, calculating monthly performance and wages became a long, error-prone task for managers.

- No Traceability: When something went wrong in production, there were no digital records, making it almost impossible to quickly find the root cause.

- Unreliable Scheduling: In a custom manufacturing environment like switchgear production, scheduling is key. But the planning process was inconsistent and relied too much on one person:

- Expert-Only Planning: Scheduling depended heavily on the planner’s personal knowledge. This led to inconsistent production plans, unbalanced work lines, and delays in updating standard work times.

- Material Delays: They lacked real-time data on when parts would arrive and be ready, which made scheduling even harder and caused production bottlenecks.

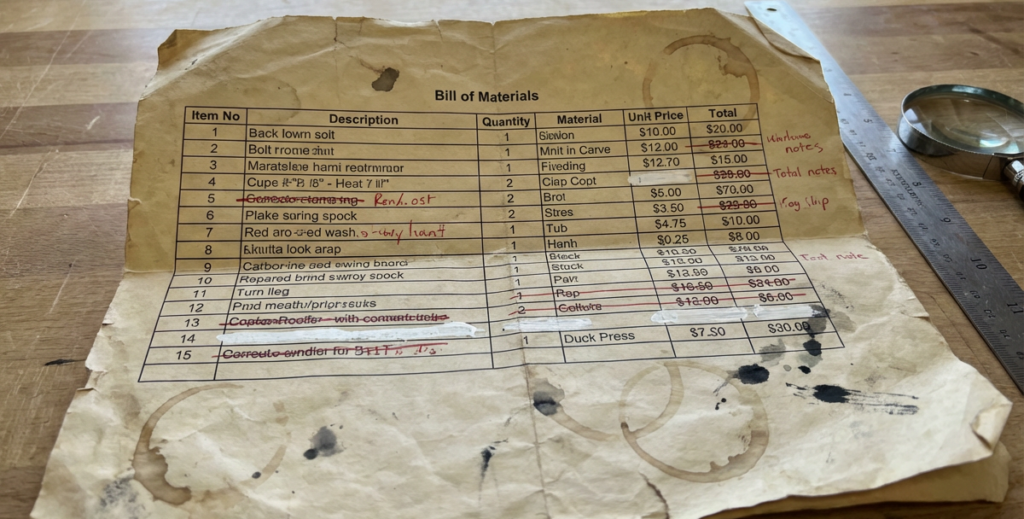

The High Cost of Uncontrolled Inventory and Waste

The custom nature of the switchgear business also created big problems with inventory and materials. Any mistake in the Bill of Materials (BOM) could lead to buying the wrong or too many materials, resulting in wasted stock. Traditional methods made it hard to use up old stock, leading to significant waste.

A major problem area was the processing of copper busbars, which are high-value materials used in large amounts. Workers cut and bend standard copper bars based on complex drawings. Historically, control happened after the fact. This meant that if a worker made even a small mistake, the material had to be scrapped. This lack of real-time oversight led to a lot of material waste and financial loss.

Finally, the team lacked good tools for real-time supervision on the shop floor. The existing ERP system could not manage the day-to-day work on the floor, leaving a big gap in their digital strategy.

The Solution: A Business-Led Digital Revolution with No-Code

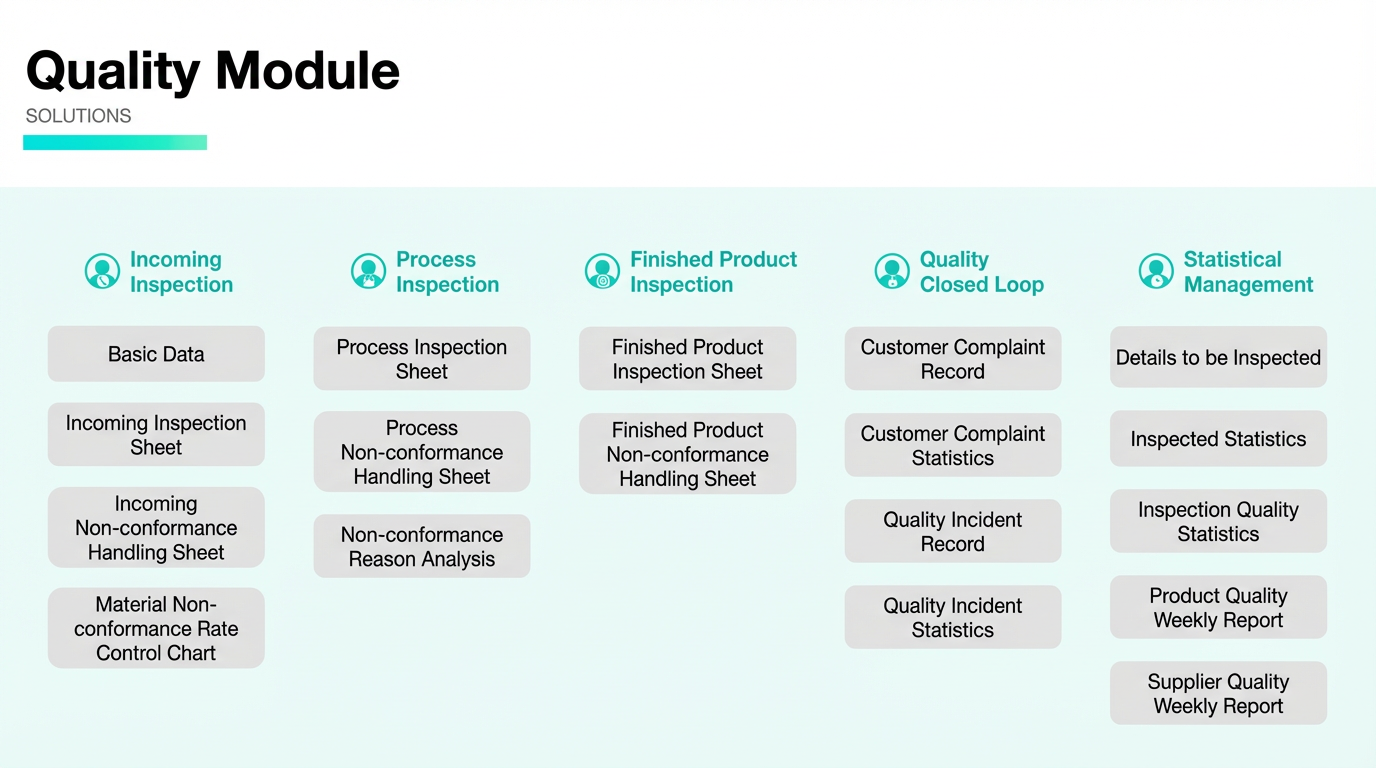

KE Electric’s Brand Cabinet Division realized that a single, expensive manufacturing execution system (MES) would not meet the needs of all the teams. They looked for a flexible, low-cost solution that their own business users could quickly build and change. They chose Jodoo, a no-code development platform.

This was a smart choice. The no-code model offered speed and flexibility that traditional IT development could not match. It allowed the business team to quickly build, test, and improve solutions, turning their deep knowledge of the factory floor into working applications.

A small In-house Digital Team, made up of the business unit head, a production manager, and a lean engineer, was formed. In less than six months, this team—without professional IT help—launched over ten applications. They created a digital system that covered every part of production: people, machines, materials, methods, and environment.

The Smart Factory: Bringing Production Out of the Dark

The team’s first goal was to get rid of the production “black box”. They wanted to move the entire production process online so managers could see real-time data and project progress. They quickly built a mobile work reporting system to replace the paper process:

- Mobile Scanning and Reporting: Each product got a unique QR code. Workers use their phones to scan the code and fill out the work order, which then moves through a digital workflow.

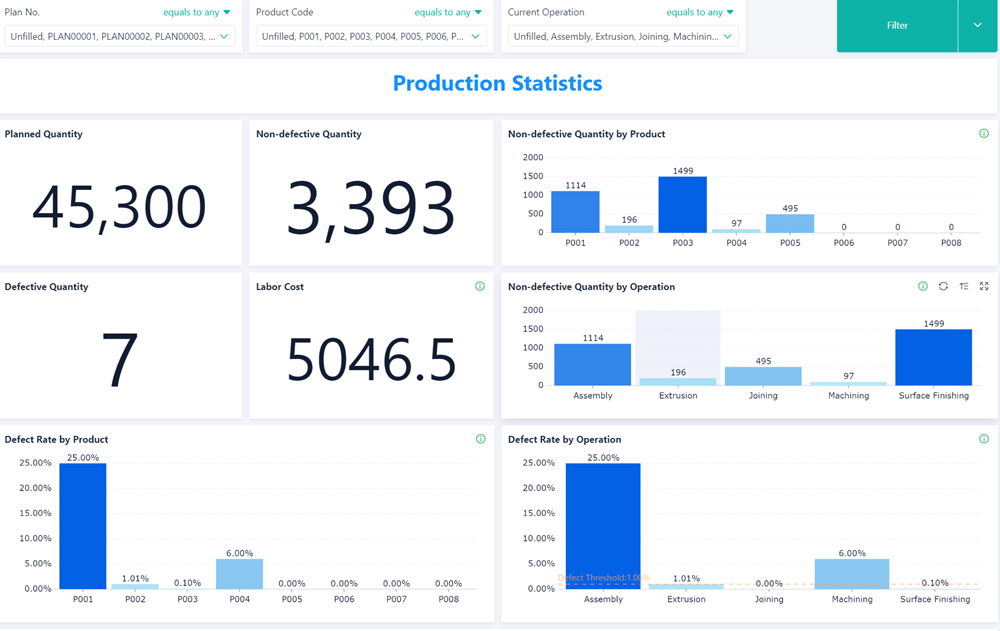

- Automatic Data Use: Moving the process online meant the data was fully used. The system automatically calculates the time spent on each step, providing accurate data for setting standard work times and managing performance. This eliminated the need for manual calculation of hours and pay, allowing managers to see production stats instantly on a dashboard.

- Foundation for Automated Scheduling: Collecting and analyzing this accurate production data created a strong base for future automated scheduling, moving away from relying on one planner’s expertise.

The Copper Busbar Management System: Turning Waste into Value

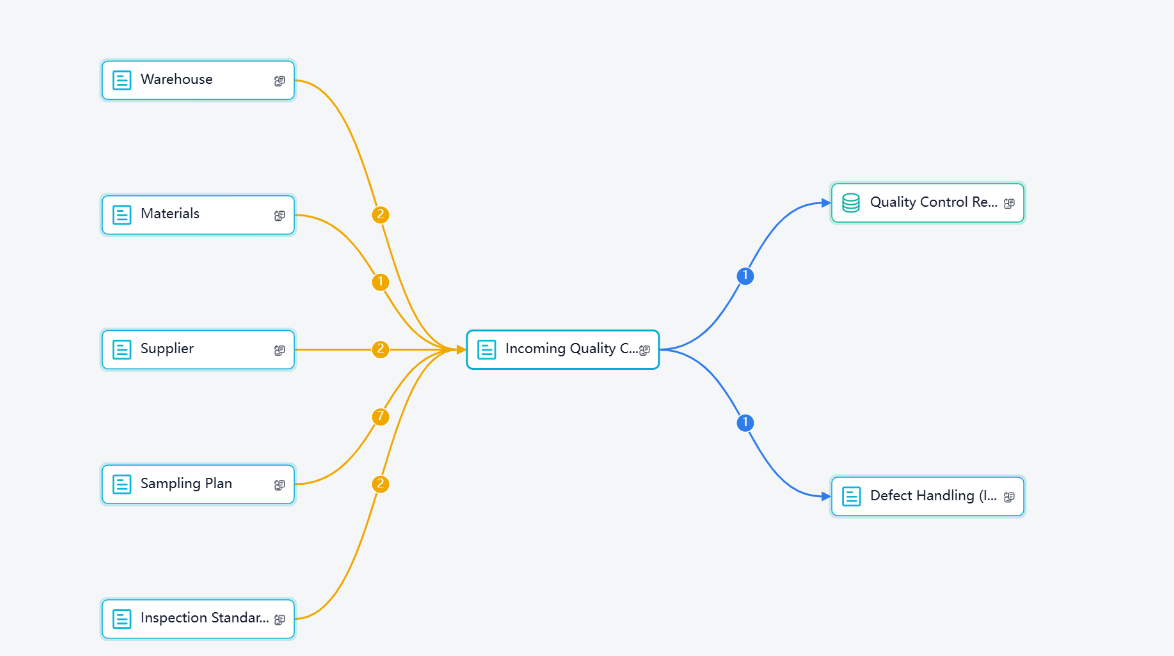

To fix the major material waste problem with copper busbars, the team built a dedicated Copper Busbar Management System using Jodoo’s data features.

- Real-Time Material Tracking: The system tracks the entire life of this high-value material, from ordering the raw material to managing the scrap.

- Accountability and Transparency: Workers must report the amount of material they take before processing and the amount of finished busbars after processing. The difference is recorded as scrap.

- Measurable Results: The clear scrap data and clear assignment of responsibility allowed the team to link scrap rates to employee performance. This immediate accountability led to a huge 84.2% reduction in material waste.

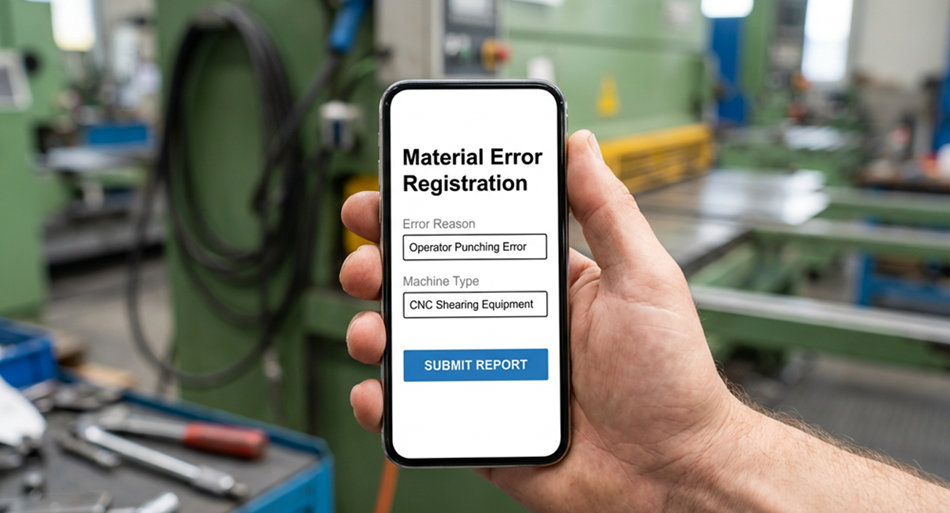

The Andon System: Empowering the Frontline to Stop Problems Fast

Using the lean manufacturing idea of the Andon system, KE Electric built a mobile-based system to empower frontline workers and ensure fast response to issues.

- Mobile Call Buttons: When a problem happens (quality issue, machine failure, missing material), the operator can immediately hit a “call” button on the Jodoo app on their phone, stopping the line.

- Instant Notification: The system instantly sends the issue via IM to the right technical staff and managers.

- Fast Response: This ensures that people arrive on-site right away to fix the problem, minimizing downtime. The system also tracks the number of issues and how fast they are fixed, which is used to measure department performance.

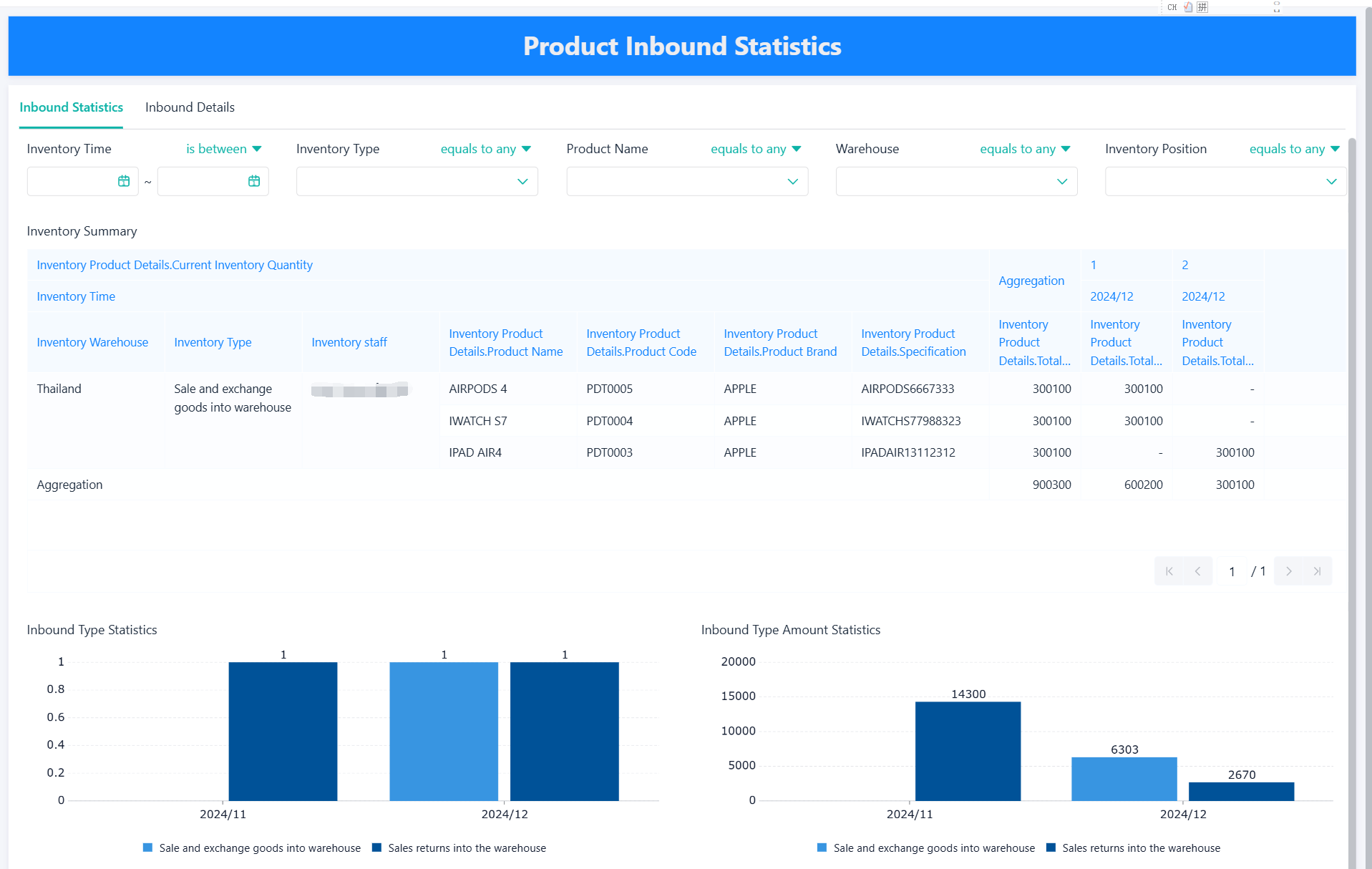

From Old Stock to Active Assets

The team also used Jodoo to manage inventory that the ERP system did not track well, especially old and slow-moving materials. They created a Stagnant Material Tracker to record every new item of old stock, assigning responsibility and the reason for its existence. This helped them use up old stock and reduce the creation of new abnormal inventory.

This wave of innovation even improved safety. The team solved a critical safety issue: making sure employees wore reflective vests when cycling inside the industrial park and on internal roads. They used Jodoo’s features to create a Reflective Vest Check-in App. Employees must take a selfie wearing the vest at the company gate to check out. This digital solution replaced manual, high-cost supervision, achieving a 100% reflective vest wearing rate and significantly reducing accidents.

The Results: A New Paradigm of Efficiency and Control

The Brand Cabinet Division’s business-led digital change delivered deep and measurable results, proving their innovative approach works and providing a significant return on investment. By putting the power of development directly into the hands of the process owners, KE Electric achieved new levels of efficiency, accountability, and safety.

The shift from fixing problems after they happen to using data to prevent them is clearly shown in the improvements below:

| Key Performance Indicator | Before Jodoo | After Jodoo | Improvement/Impact |

|---|---|---|---|

| Material Waste (Copper Busbar) | High, unquantified daily losses | 84.2% reduction in | Direct cost savings and better resource use. |

| Obsolete Inventory Value | Over $500,000 in stagnant stock | 65% reduction in obsolete stock value | Significant reduction in capital tied up in inventory. |

| Production Reporting Time | 40+ man-hours per month | 95% reduction to less than 2 man-hours per month | Eliminated manual pay calculation and enabled real-time traceability. |

| Safety Compliance (Reflective Vests) | <50%, manually supervised | 100% compliance, fully automated | Improved worker safety and reduced non-motor vehicle accidents. |

| Production Anomaly Response Time | Hours or days | Minutes, via real-time Andon alerts | Shifted from reactive to proactive problem-solving. |

| Application Development & Deployment | 6-12 months per app (via IT) | 10+ apps in less than 6 months (via 8 business developers) | Empowered business users to drive their own digitalization. |

The most important result is the change in how the company views its data. As the head of the Brand Cabinet Business Unit said:

“Manufacturing not only needs energy like water, electricity, gas, and heating; it needs data as a new energy source. We believe data is wealth, data is the new energy, and data will be an effective tool for high-quality development. By mining management value from data, we can significantly improve per capita efficiency and overall performance. Although data is intangible, its value is immense.”

The no-code approach allowed the business unit to quickly build a digital base, collecting data that supports better planning and scheduling. Valuable production experience is no longer just in the minds of workers; it is now captured in objective, tangible data, creating a strong foundation for KE Electric’s full digital change.

Future Outlook: Data as the New Energy for a Manufacturing Leader

KE Electric’s journey has completely changed what digitalization means inside the company. What was once a distant idea is now a real, working system on the factory floor, driven by the people closest to the work. The success of the Brand Cabinet Division has created a powerful internal model for innovation, proving that with the right tools, business teams can and should control their own digital future.

Looking ahead, KE Electric plans to keep building digital applications, moving toward a management system that connects Jodoo + MES + ERP + OA:

- Keep the Digital Culture Going: They will continue to push the idea of digitalization, using data to communicate, replacing paper, and using data to manage people and processes.

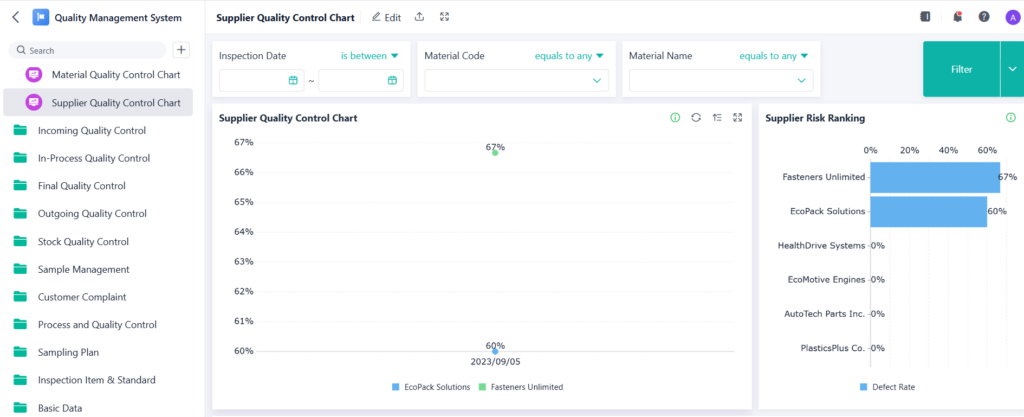

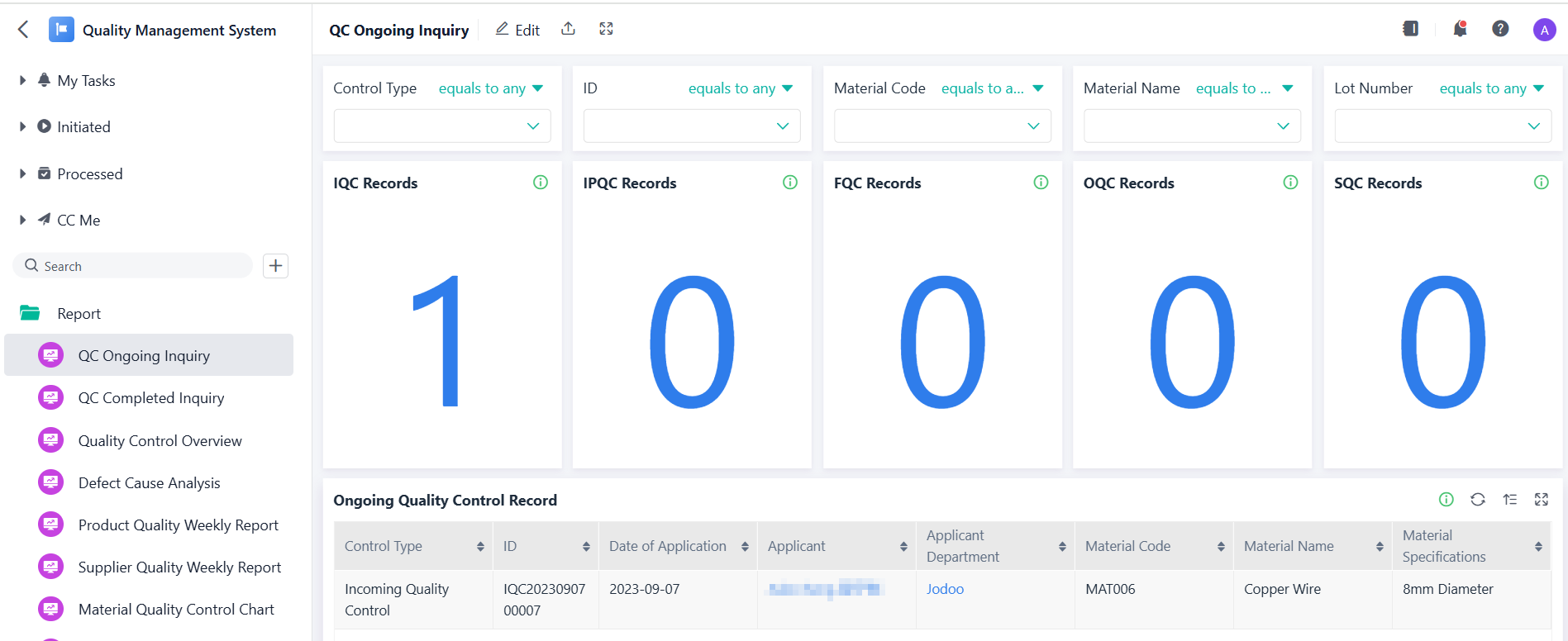

- Build a Full Digital Archive: Future projects will include quality management and after-sales service, creating a full digital history for each switchgear product—from raw material to quality control and service records—all accessible via a QR code.

- Achieve Automated Scheduling: With the data foundation now in place, the final goal of automated scheduling and a scientific indicator system is within reach.

The spirit of innovation is key for KE Electric. By choosing a no-code platform, KE Electric has secured its ability to quickly adapt and innovate, ensuring its digital future is controlled by the business users closest to the action, not by the limits of traditional IT systems.

Ready to unlock the “new energy” in your manufacturing operations and empower your teams to drive digital innovation?