52%

Higher Order Processing Efficiency

61%

Enhanced HR Efficiency

42%

Accelerated Financial Workflows

“After six years of use and continuous functional improvements, Jodoo has transformed our business and financial processes—accelerating growth, reducing costs, and improving efficiency. We will continue leveraging Jodoo to drive OPPO’s digitalization.“

— OPPO Management

In today’s rapidly evolving business landscape, digital transformation is not just an option but a necessity for companies aiming to maintain a competitive edge. OPPO faced significant operational challenges inherent in traditional wholesale and retail. With a vast network of over 10,000 dealer customers, managing complex order flows, human resources, and financial processes manually led to inefficiencies, data silos, and substantial operational overhead. This case study explores how OPPO partnered with Jodoo to implement a comprehensive 0-N information system upgrade, achieving remarkable cost reductions and efficiency gains across its entire workforce.

About OPPO

Founded in 2004, OPPO is a globally recognized leader in smart device manufacturing and mobile internet services, with operations in over 50 countries and regions. Leveraging a network of more than 400,000 sales outlets and 2,500 service centers, OPPO shares the beauty of technology with users worldwide.

In 2023, OPPO ranked 12th on the “2023 Global Unicorn List,” with an impressive revenue of approximately USD 23 billion.

The subsidiary collaborating with Jodoo, as a vital regional agent, is responsible for the market and sales management of the OPPO brand across international markets like Indonesia, the Philippines, Malaysia, Singapore, China, and Japan. The company’s commitment to excellence and innovation drives its continuous pursuit of operational superiority.

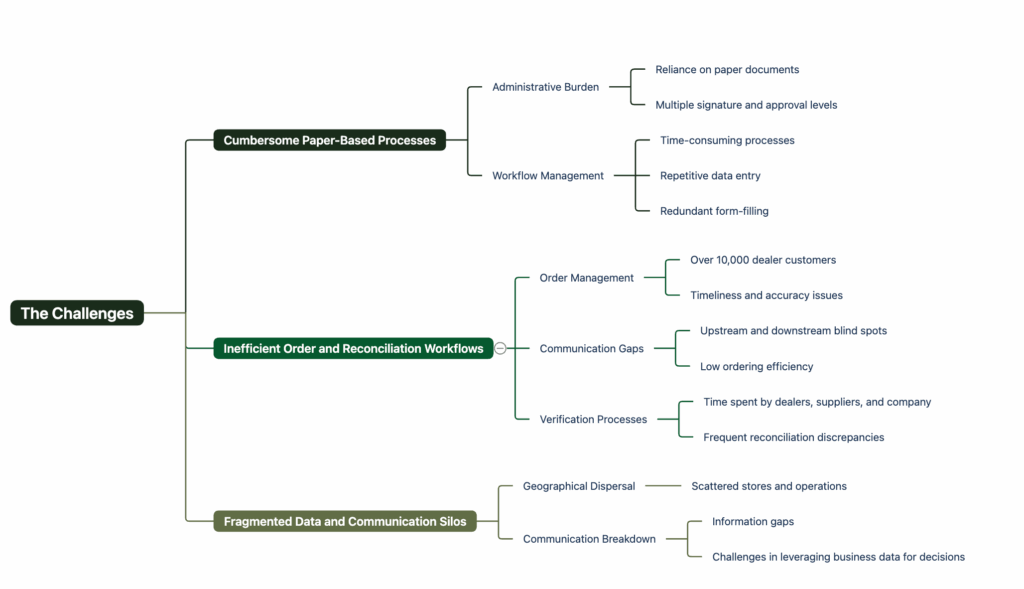

The Challenges: Navigating Traditional Hurdles

Before embracing informatization, OPPO grappled with several critical pain points that hindered its growth and efficiency:

Cumbersome Paper-Based Processes

The reliance on paper documents for applications, approvals, and notifications created an enormous administrative burden. Manual, multi-level signature and approval processes consumed excessive time and energy, making it difficult to consolidate and manage workflows effectively. Business statistics often involve repetitive data entry and redundant form-filling, leading to unnecessary workload.

Inefficient Order and Reconciliation Workflows

Managing over 10,000 dealer customers meant that the timely and accurate processing of orders and payments was a monumental task. Blind spots in upstream and downstream communication led to low ordering efficiency and frequent discrepancies in reconciliation. Dealers, suppliers, and the company itself spent excessive time verifying data, significantly slowing down business operations.

Fragmented Data and Communication Silos

With stores and operations scattered across diverse geographical locations, communication breakdowns were common. This resulted in information gaps and “data silos,” making it challenging to fully leverage valuable business data for informed decision-making.

The Jodoo Solution: A Blueprint for Digital Transformation

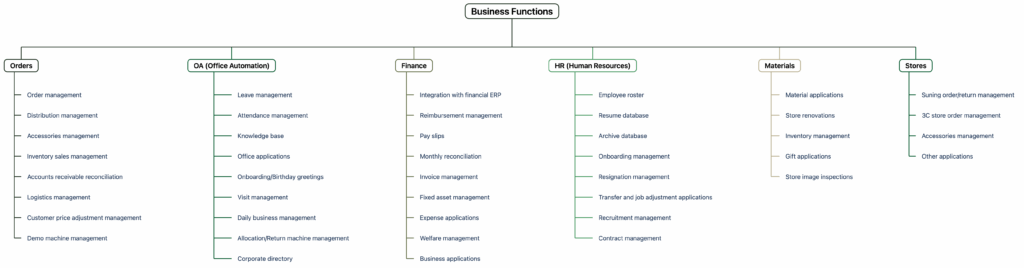

To overcome these management pain points and drive comprehensive informatization, OPPO implemented Jodoo across its high-volume transactional and HR processesbusiness and personnel management scenarios. The solution focused on creating a unified, transparent, and efficient digital ecosystem.

Unified Online Form Submission and Data Processing

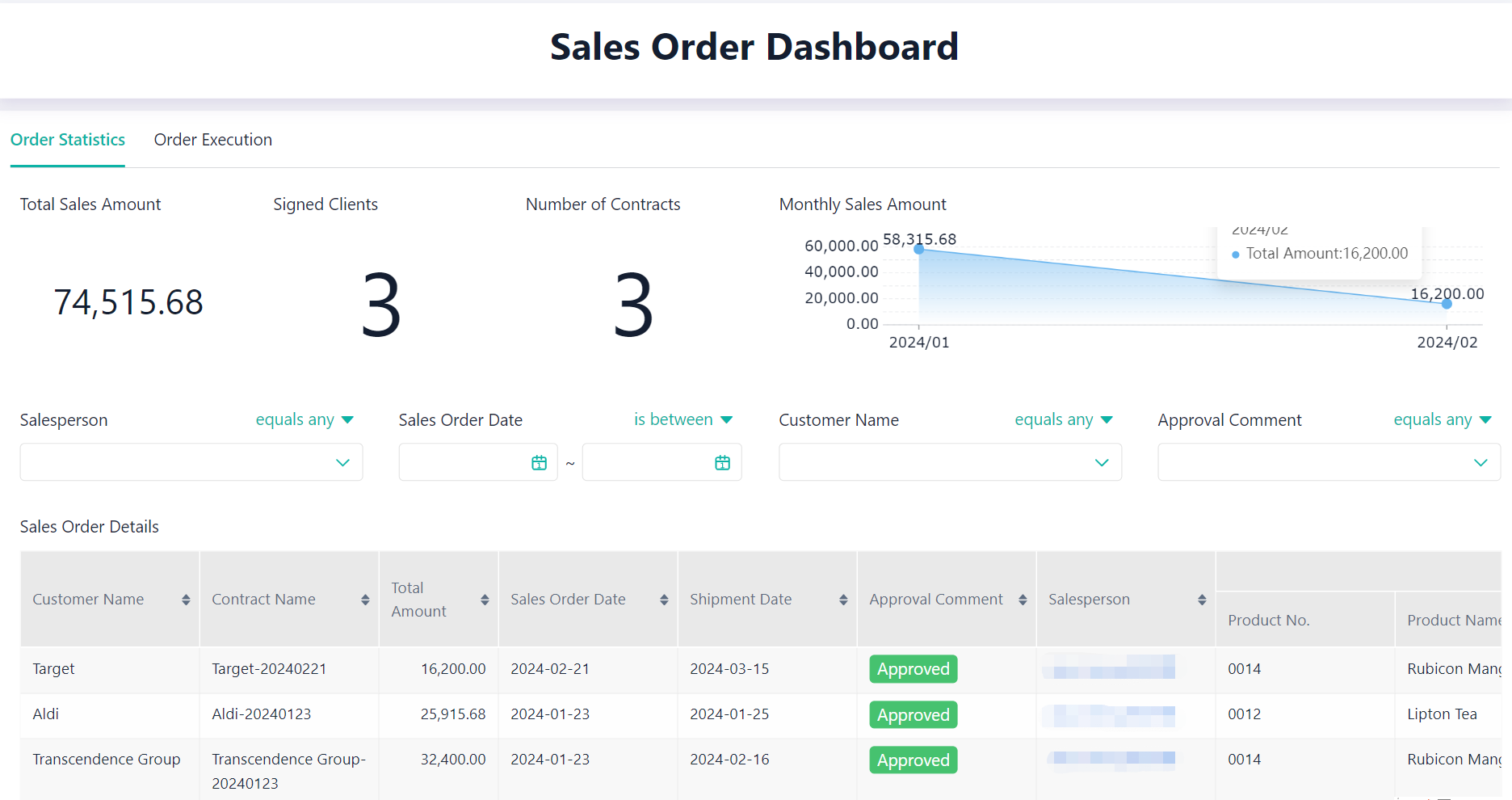

Jodoo enabled OPPO to transition from chaotic paper-based processes to streamlined online form submissions. This allowed for anytime, anywhere data entry, real-time circulation, and automatic updates, significantly reducing statistical complexities. A powerful “data engine” within Jodoo rapidly processed information, generating personalized reports with a single click. This facilitated real-time display of front-end and back-end data, achieving centralized aggregation, analysis, and processing of all business data.

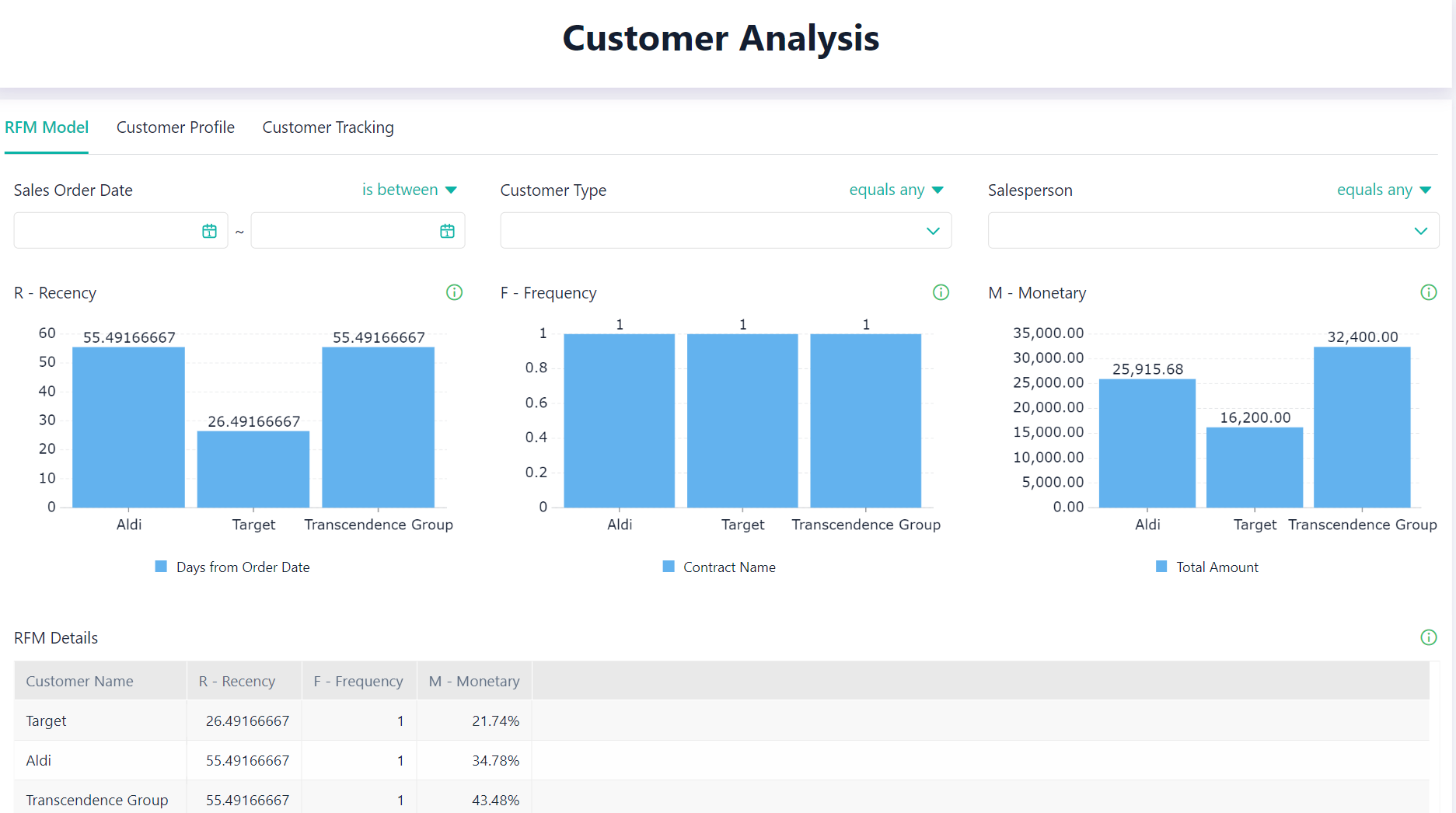

Jodoo revolutionized dealer interactions by providing open form permissions, ensuring transparent management of all ordering processes with zero data errors. By unifying entry points for ordering and reconciliation, and implementing online approvals for every stage, OPPO achieved standardized management for its dealers. This approach also guaranteed accurate and effective data retention, establishing a solid foundation for future statistical analysis and strategic planning.

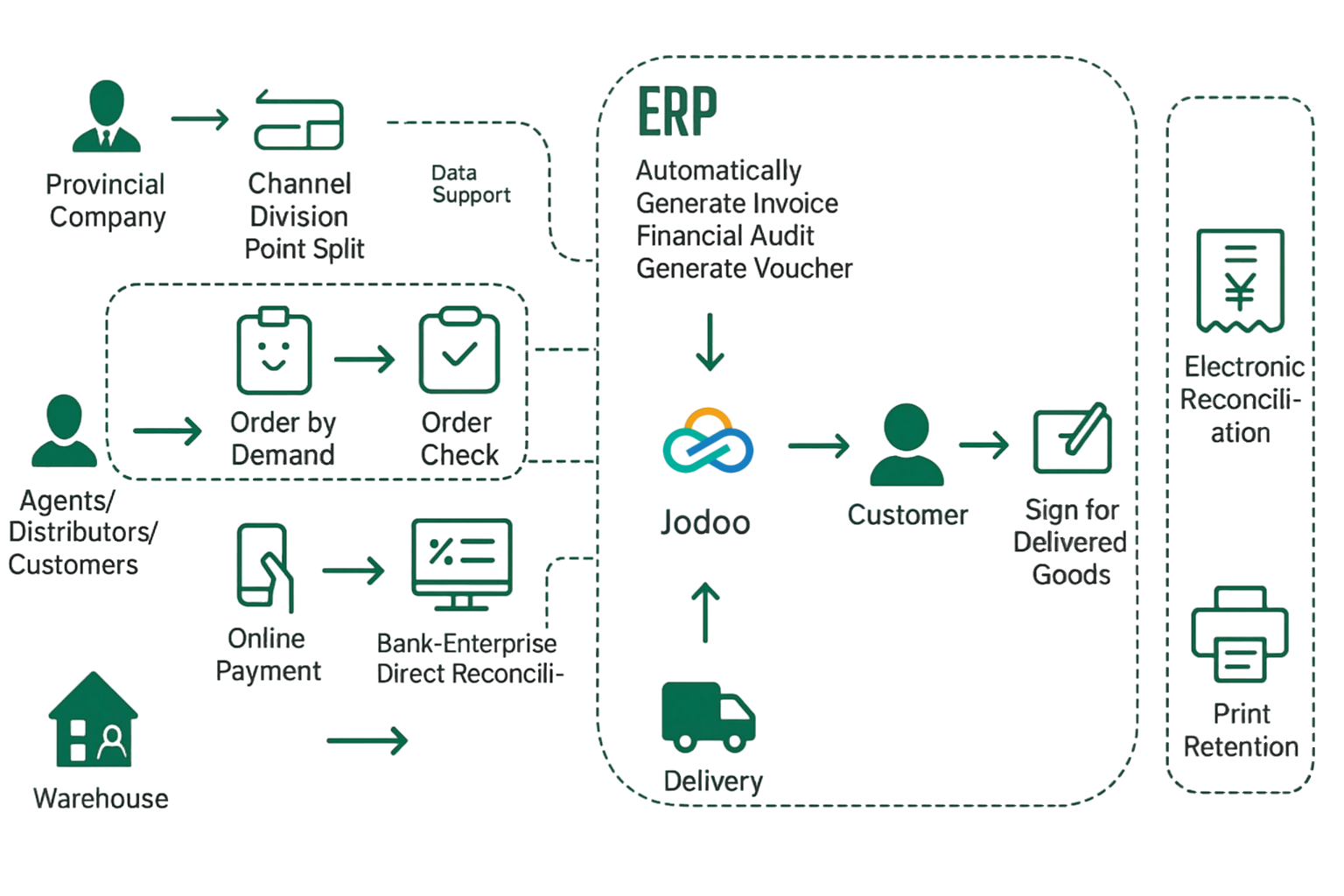

Seamless ERP Integration and Rapid Financial Reconciliation

One of Jodoo’s most impactful features was its seamless integration with existing ERP systems, such as SAP. This API-driven connectivity allowed dealers to establish direct links with OPPO, facilitating real-time data transfer for orders, payments, balances, and reconciliations. A standout benefit was the ability for customers to receive payment receipts within an astonishing 5 minutes, dramatically improving financial efficiency and customer satisfaction.

No-Code Retail HR System for Comprehensive Employee Management

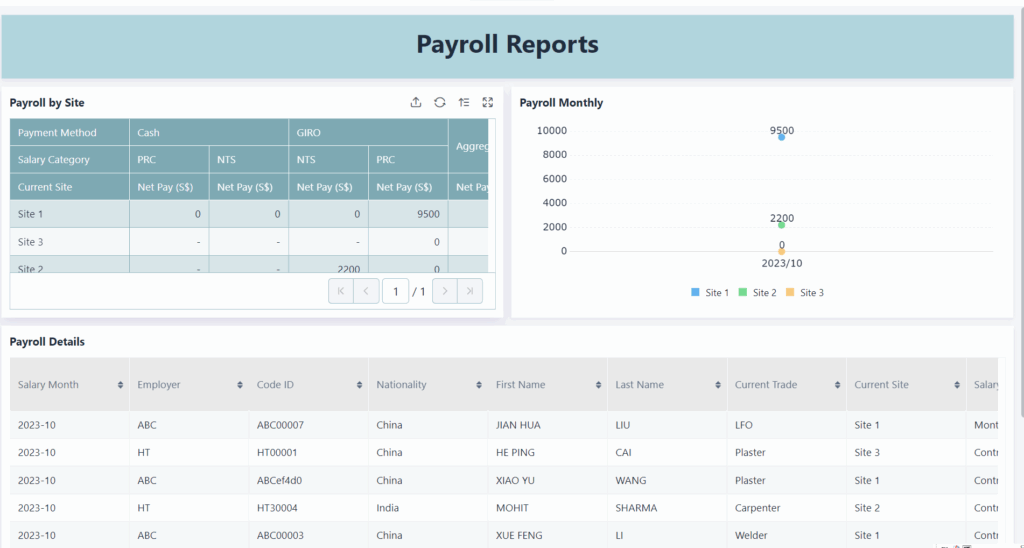

OPPO leveraged Jodoo’s no-code capabilities to construct a robust retail HR system tailored for managing its entire workforce. This initiative began with extensive internal discussions to identify pain points and gather HR management requirements from various regions. After clear communication with management and defining core needs, the system was designed step-by-step, encompassing daily report management, performance appraisal, and payroll. This resulted in a complete and integrated HR management system that enhanced accuracy and timeliness.

Typical Application Scenarios: Real-World Impact

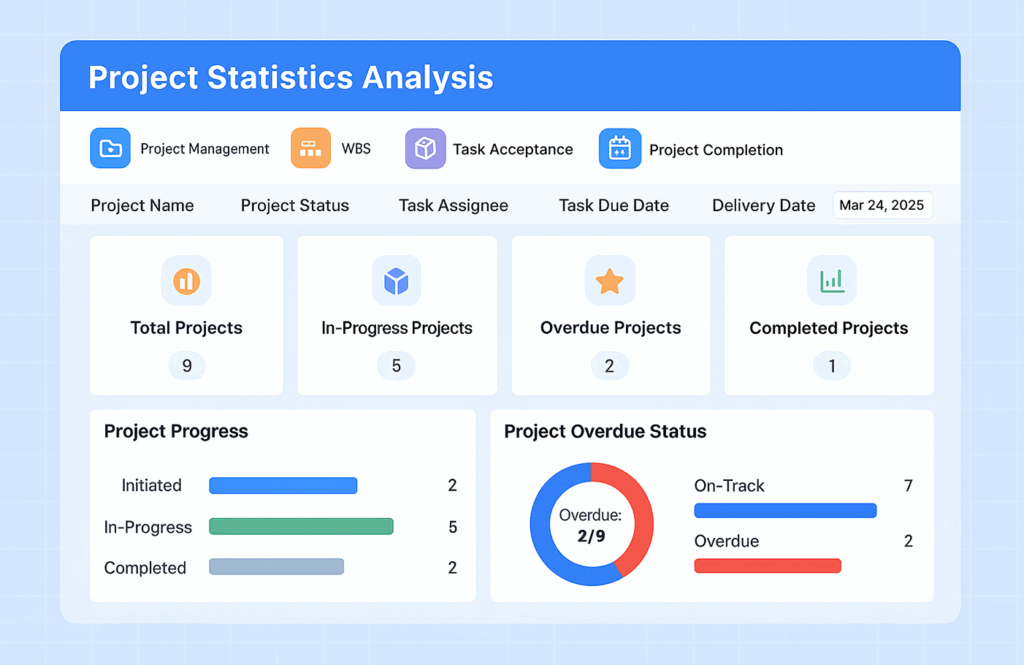

Below are four high-impact scenarios illustrating how a unified no-code platform modernizes operations for a large, multi-region smart device enterprise managing thousands of partners, job sites, and field personnel.

Scenario 1: Unified Ordering & Allocation

The ordering lifecycle was transformed into three synchronized flows:

1. Order Flow (Allocation Engine):

- Core center for different levels of allocation rules, combining two strategies: “allocating based on each site’s needs” and “replenishing when items are sold”.

- Automated roll-down of allocation targets and roll-up validation of downstream orders.

- Dashboards highlighted variance, fulfillment readiness, and exception queues.

2. Funds Flow (Bank–ERP Linkage):

- A “bank robot” matched inbound transactions to customer accounts using predefined mapping tables.

- Automatic payment recognition posted to ERP, eliminating manual cash application and “orphaned funds.”

3.Information Flow (Proactive Transparency):

- Real-time account balance (rebates, adjustments, returns, payments) pushed via API into the platform and WhatsApp/mobile notifications.

- Logistics milestone updates triggered customer-facing alerts.

- Self-service statements reduced inbound status calls.

Key Improvement:

- Allocation model generation reduced from hours of spreadsheet work to mere seconds.

- Significant reduction in unidentified payments.

- Faster order-to-release cycle, minimizing disputes and fostering improved trust.

- Enhanced multi-perspective analytics, including:

- Product demand velocity

- Regional order mix

- Customer consumption trends

- Replenishment triggers

Scenario 2: Performance & Compensation Intelligence

1. Flexible KPI Modeling:

- Rule abstraction tagged metrics as “interval” or “completion,” allowing formulas to adapt without constant admin rebuilds.

- Users triggered recalculation simply by viewing their dashboard, reducing back-office intervention.

2. Multi-Dimensional Role Evaluation:

- Promoter and trainer data (sales, mix, training duration) processed through a staged calculation pipeline and rendered in under 10 seconds, even with 100k+ monthly rows.

- Trainer ranking dashboards highlighted score shifts and outliers.

Key Improvement:

- KPI consolidation time reduced from 2–3 days to approximately 1 hour via platform-driven processing.

- HRs are freed from repetitive formula maintenance.

- Transparent individual performance views improved intrinsic motivation.

- Leadership gained a province-to-individual drill path for early intervention.

Scenario 3: Field Daily & Weekly Reporting

- Structured Workflow Forms: Captured daily/weekly updates, auto-linking to role, manager, geography, and historical performance.

- Non-Submission Detector: Integrated staff master data with report logs, excluding off-duty personnel (holiday calendar integration).

- Automated Reminders: Sent only to missing contributors, reducing disruptive notifications.

- Dual-Layer Permissions: Local managers could access their domain while headquarters leadership could view roll-up data.

- Dashboards: Allowed managers to filter “today vs yesterday” submission gaps.

Key Improvement:

- Leadership gained real-time clarity into field traction and blockers.

- HR staff saved ~30 minutes per region per day on compliance tracking.

- Increased adoption due to embedded feedback loops and lighter cognitive load.

- Reusable patterns leveraged for other mandatory processes (e.g., safety checks, site inspections, punch resolution).

Scenario 4: Mobile Process Automation & Asset Traceability

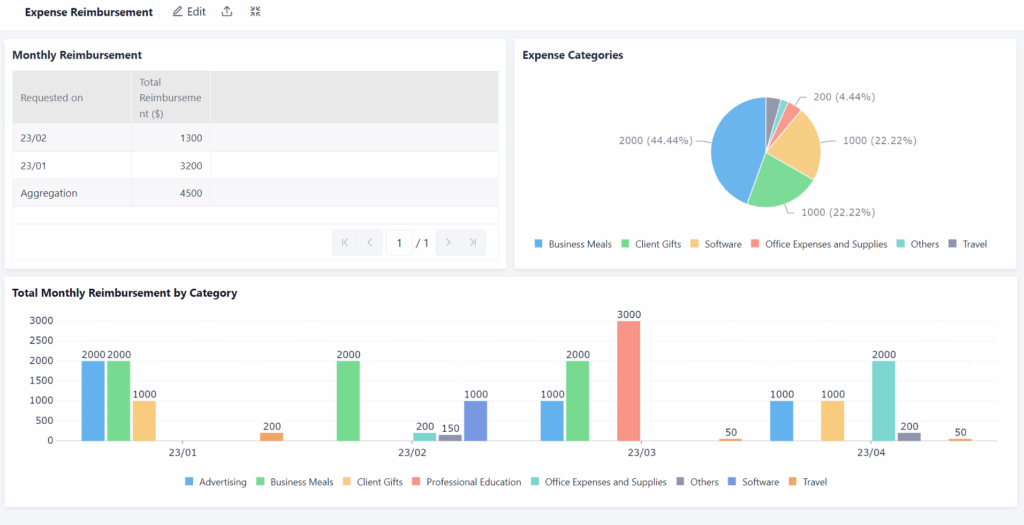

1. Expense & Policy Linkage:

- Mobile submissions with pre-tagged accounting subjects auto-produced import-ready finance files.

- Linked original policy approvals to reimbursement claims, eliminating re-clarification loops.

2. Process Analytics:

- Flow analytics revealed bottlenecks and aging tasks, enabling targeted leadership redesign (e.g., parallel approvals).

3.Material & Vendor Coordination:

- Unified request → dispatch → receipt loop for store fixtures, job site materials, and branding assets.

- Vendor participation throughout the product lifecycle reduced gaps and rework.

4.Fixed Asset & Equipment Tracking:

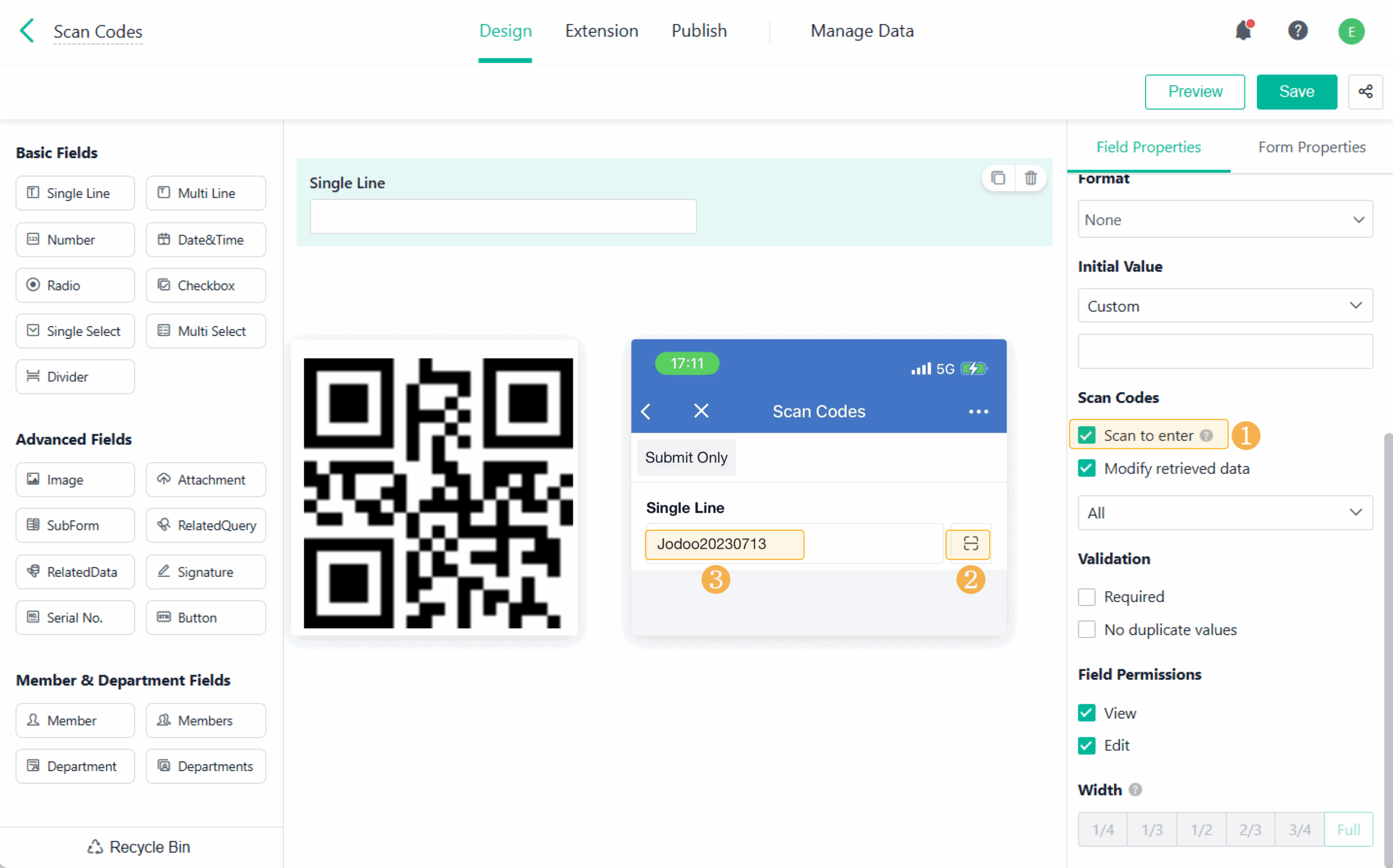

- Bulk-generated QR tags allowed scans to view status, submit repairs, or update conditions.

- Real-time ledger updates improved audit and spot-check readiness.

5.Price Adjustment & Serial Control:

- Serial (device “fingerprint”) matched to customer/site, exposing unregistered inventory for centralized pricing actions.

- Distributors filtered relevant serials while dashboards tracked batch compliance and variance feedback loops.

6.Engagement Automation:

- Scheduled HR-driven “welcome” and birthday messages reinforced culture with minimal manual effort.

Key Improvement:

- Cycle times collapsed, reducing approval stalls.

- Fewer finance data entry errors; accelerated period close confidence.

- Full material lifecycle visibility improved ROI on asset deployment.

- Audit and compliance strengthened through continuous, structured data capture.

- Enhanced employee experience through recognition and reduced administrative friction.

Conclusion: A Future of Continued Innovation

OPPO’s journey with Jodoo exemplifies how a strategic investment in informatization can lead to significant operational improvements, cost reductions, and enhanced efficiency. By addressing critical pain points in order management, HR, and finance, Jodoo provided a flexible and scalable platform that empowered OPPO to streamline processes, improve data accuracy, and foster better collaboration across its vast network. This digital transformation has not only solved immediate challenges but has also laid a strong foundation for OPPO’s continued growth and innovation in the competitive smart device market.

As OPPO looks to the future, its partnership with Jodoo will continue to drive its informatization efforts, ensuring agility and sustained success in an ever-changing global landscape.

Ready to explore how these patterns map to your asset project pipeline, field operations, or distributor ecosystem? Your next efficiency breakthrough is likely a design pattern—not a massive rebuild. Let’s operationalize it.