50%

Faster Equipment Fault Handling

65x

More Efficient Spare Parts Management

17

Integrated Online Systems

“Jodoo, as a no-code application development platform, can quickly respond to business changes, and it is very easy to get started. Business personnel can also quickly master it, which is very suitable for the current rapidly changing business situation.”

— SAIC Volkswagen Management Team

The SAIC Volkswagen New Energy Vehicle Plant is a milestone for the Volkswagen Group as its first global facility dedicated to manufacturing vehicles based on the cutting-edge MEB (Modular Electric Drive Matrix) platform. Construction began in October 2018, and by November 2019, the plant had completed its first fully-processed prototype. Official production commenced in October 2020, marking the beginning of SAIC Volkswagen’s journey into a new era of electrification and intelligent technology.

As more than just a production facility, the plant serves as an innovation hub for SAIC Volkswagen. It is designed to accelerate groundbreaking research and drive the implementation of intelligent technologies, driving forward-thinking advancements in the automotive industry. With its focus on innovation and sustainability, the Anting plant is a key driver of SAIC Volkswagen’s vision for the future of mobility.

The Challenge: Navigating Complexity in a Fast-Paced Industry

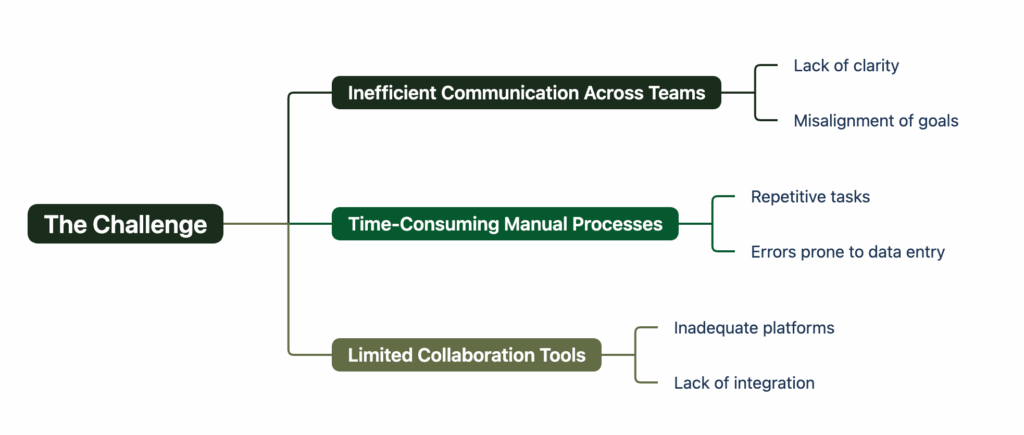

SAIC Volkswagen’s New Energy Vehicle Plant represents the future of mobility, blending electrification and intelligent technology. However, building and operating such an advanced facility came with unique challenges:

Inefficient Communication Across Teams

During the plant’s construction, multiple suppliers were responsible for various projects. As work advanced, issues such as quality concerns, safety challenges, and installation inefficiencies arose. The lack of a streamlined communication process led to delays and mismanagement.

Time-Consuming Manual Processes

Problem tracking relied on online forms and manual Excel updates, creating bottlenecks in resolution cycles. This reactive approach hindered progress and slowed decision-making.

Limited Collaboration Tools

Suppliers struggled with unfamiliar systems, preferring mobile-friendly solutions. Without proper collaboration tools, the planning department and suppliers faced difficulties in addressing issues efficiently.

The Solution: Jodoo’s No-Code Innovation

Recognizing the need for agility, SAIC Volkswagen partnered with Jodoo to implement a no-code platform tailored to their unique requirements. Take the problem-solving process as an example — a more standardized process was developed:

1. Problem Submission: A maintenance department employee submits a problem ticket.

2. Acceptance & Resolution: The planning department and supplier accept the ticket and address the issue. Three resolution options are available:

- Resolved: The issue is fully addressed.

- Completed by a specified completion date: A timeline is set for resolution.

- Disapproved: The ticket is returned to the initiator for clarification or additional action.

3. Tracking: Disapproved tickets are followed up by maintenance staff until resolved.

4. Review: Resolved tickets undergo a review by maintenance technicians to confirm completion.

5. Confirmation: If the review is satisfactory, the process ends. If not, the issue is returned to a previous step for further action.

Jodoo empowered SAIC Volkswagen to build an online office cloud platform, enabling rapid development and deployment of applications without coding expertise. Over 8,000 users actively engaged with the platform, contributing over 30,000 data entries across 17 live systems.

Overcoming Operational Hurdles: Key Areas of Impact

SAIC Volkswagen leveraged Jodoo to address specific pain points across its operations, leading to significant improvements in efficiency and data management. Three key modules highlight the profound impact of this digital transformation:

Revolutionizing Spare Parts Management

Before Jodoo: Previously, managing spare parts was a paper-intensive process, fraught with manual data entry, delayed inventory updates, and inefficient physical checks. This led to significant time loss and inaccuracies, hindering timely maintenance and operational flow.

With Jodoo: SAIC Volkswagen implemented a comprehensive spare parts module on Jodoo. This involved importing the entire spare parts list into a centralized system, with aggregated tables automatically updating inventory levels based on inbound and outbound movements. Maintenance personnel can now query spare part locations and quantities via their mobile phones, enabling on-demand collection. The system also facilitates quantity verification through material number linkages and supports random spot checks with automated information linking.

Key Improvement: The spare parts module delivered an astounding 65-fold increase in efficiency for spare parts collection and related operations. The ability for maintenance personnel to access real-time information and manage inventory from their mobile devices has dramatically improved workflow and reduced operational bottlenecks.

Streamlining Project Management and Problem Resolution

Before Jodoo: Project-related issues were previously collected manually, often involving transferring data from internal communication platforms to spreadsheets. This process was time-consuming, led to prolonged resolution cycles, and lacked the agility required for rapid response to critical issues.

With Jodoo: A robust project management module was developed, featuring a streamlined online process form. This form guides issues from proposal through acceptance, measure formulation, implementation, tracking, and final completion. Suppliers and planners were integrated into this system, ensuring all problems are addressed and resolved online.

Key Improvement: The project module resulted in a 50% increase in efficiency from problem proposal to rectification. The online system eliminated geographical and time constraints, allowing maintenance personnel to raise issues instantly and ensuring that suppliers and planners receive immediate notifications for prompt action.

Enhancing Equipment Management and Fault Handling

Before Jodoo: Equipment operation and debugging issues were traditionally recorded on paper, leading to unclear responsibilities and delayed notifications to the correct technicians. This often resulted in misreported problems and prolonged equipment downtime.

With Jodoo: SAIC Volkswagen implemented a fault downtime record process form. This digital form captures critical details such as fault start and end times, impact on workshop production, and fault descriptions. It automatically pushes tasks to the responsible technicians’ to-do list, complete with reminder functions for timely resolution. Unresolved issues are tracked in an outstanding issues log for continuous monitoring.

Key Improvement: The equipment module led to a 50% increase in efficiency for resolving equipment operation and debugging problems. Technicians now receive daily updates on equipment faults, enabling them to quickly assess on-site situations and address issues proactively, significantly reducing downtime and improving overall operational continuity.

The Future of Digitalization at SAIC Volkswagen

SAIC Volkswagen’s successful adoption of Jodoo underscores the platform’s capability to drive significant operational improvements and foster digital innovation within large-scale manufacturing environments. As a no-code application development platform, Jodoo provides the flexibility and ease of use necessary to adapt to rapidly changing business needs, empowering even non-technical personnel to contribute to digital transformation.

Looking ahead, SAIC Volkswagen plans to further expand its use of Jodoo, continuing to build a more comprehensive, efficient, and secure company system. This ongoing partnership exemplifies how no-code solutions can serve as a cornerstone for advanced manufacturing, enabling companies to achieve greater agility, efficiency, and responsiveness in a competitive global market.

Ready to transform your operations and empower your teams with no-code innovation? Discover how Jodoo can help your business achieve similar success.