60%

Enhanced Supplier Interaction

50%

Increased Digitalization

50%

Streamlined Operations

Since Tenneco started using Jodoo in 2022, its systematic approach has earned client recognition and trust. Moving all forms to Jodoo, with added reporting and integration functions, has reduced usage constraints. It has partly increased the digitalization of each factory, boosting their confidence and enthusiasm for electronic operations. It has also improved real-time interaction with suppliers, partially increasing their digitalization.

— Tenneco Management Team

Established in 1999, Tenneco Automotive is a joint venture under the global Tenneco Group, specializing in the development, production, and sales of automotive exhaust systems. Tenneco’s product portfolio includes exhaust manifolds, catalytic converters, mufflers, and advanced diesel after-treatment systems. Supported by Tenneco’s global resources and the expertise of its local R&D center, the company excels in technology, pricing, quality, and service, earning high praise from its clients.

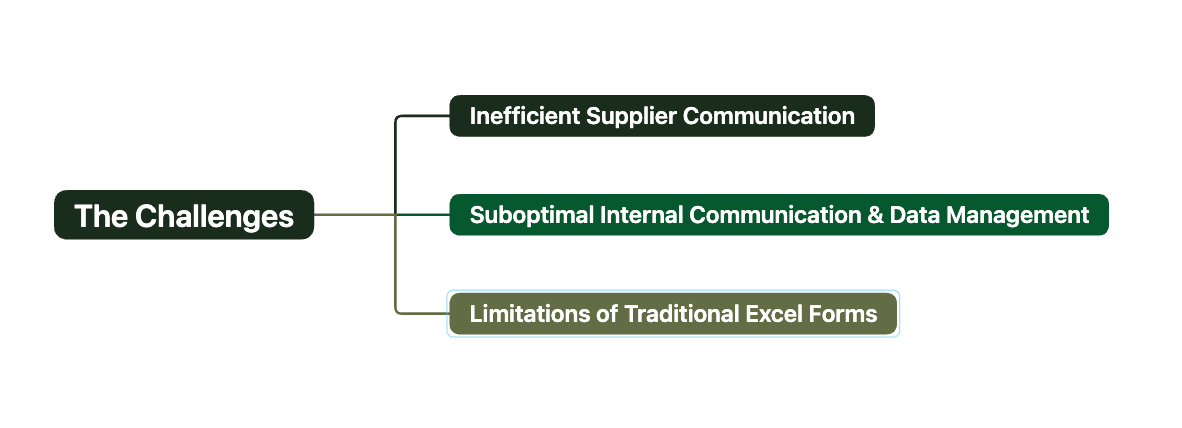

The Challenges: Navigating a Complex Supply Chain

Before adopting Jodoo, Tenneco faced several significant operational hurdles, primarily stemming from outdated communication methods and inefficient data management:

Inefficient Supplier Communication

Communication with suppliers largely relied on traditional methods such as email and WhatsApp. This fragmented approach made it difficult to retain and trace communication records, track progress effectively, or view real-time updates. Manual searching for information was time-consuming and often led to delays in critical processes.

Suboptimal Internal Communication and Data Management

Internally, Tenneco heavily depended on numerous Excel forms scattered across various shared drives. This decentralized system led to a lack of concentration, difficulty in correlating data, and an inability to quickly and accurately summarize information. The absence of a streamlined process flow hindered effective tracking and closed-loop management. Furthermore, critical attachments could not be retained alongside relevant data, and most information was only accessible via the company’s intranet, limiting mobile access and overall efficiency.

Limitations of Traditional Excel Forms

Factories primarily used Excel for managing incoming material inspections and other vital forms. However, Excel’s limited computing capabilities and frequent macro errors posed significant challenges. With six factories, each maintaining its own Excel sheet, data aggregation became cumbersome, leading to massive data volumes that often caused computers and software to freeze or malfunction.

The Jodoo Solution: A Phased Approach to Digital Transformation

To overcome these challenges, Tenneco partnered with Jodoo to implement a comprehensive digital transformation strategy, executed in two key phases:

Step 1: Building the Internal Framework

Jodoo facilitated the creation of a robust internal system by categorizing supplier quality management into three core modules: operational supplier quality, new project supplier quality, and supplier quality improvement. Through a phased implementation, all previously scattered data, predominantly in Excel forms on shared drives, were migrated to the cloud. This centralization allowed for seamless linking and correlation between various forms, creating a unified data environment.

Step 2: Establishing External Connectivity

Beyond internal optimization, Jodoo enabled Tenneco to build an interconnected external system, fostering real-time collaboration and information sharing with key suppliers. This was particularly crucial for new project development and efficient handling of quality issues.

Over approximately six months, Tenneco’s sub-supplier management team, working closely with Jodoo, iteratively developed and refined around 40 applications. The implemented applications include, but are not limited to:

- Incoming Material Inspection Registration Form

- Supplier Claims Registration and Circulation

- Supplier Information Maintenance

- Supplier Management and Improvement

- Supplier Monthly and Annual Performance Tracking

- TOP Supplier Management

- SPPM (Supplier Performance Management) Exceeding Standard Improvement and Enhancement

- Annual Process Review

- Potential Supplier Review

- Process Change Management

- Joint Review Processes

- Special Case Processing and Tracking Table

- Quality Analysis Framework Table

- New Project Development and Tracking (Enterprise Interconnection)

Typical Application Scenarios: Real-World Impact

Jodoo’s flexible platform allowed Tenneco to address specific pain points through tailored applications, demonstrating significant improvements in two key areas:

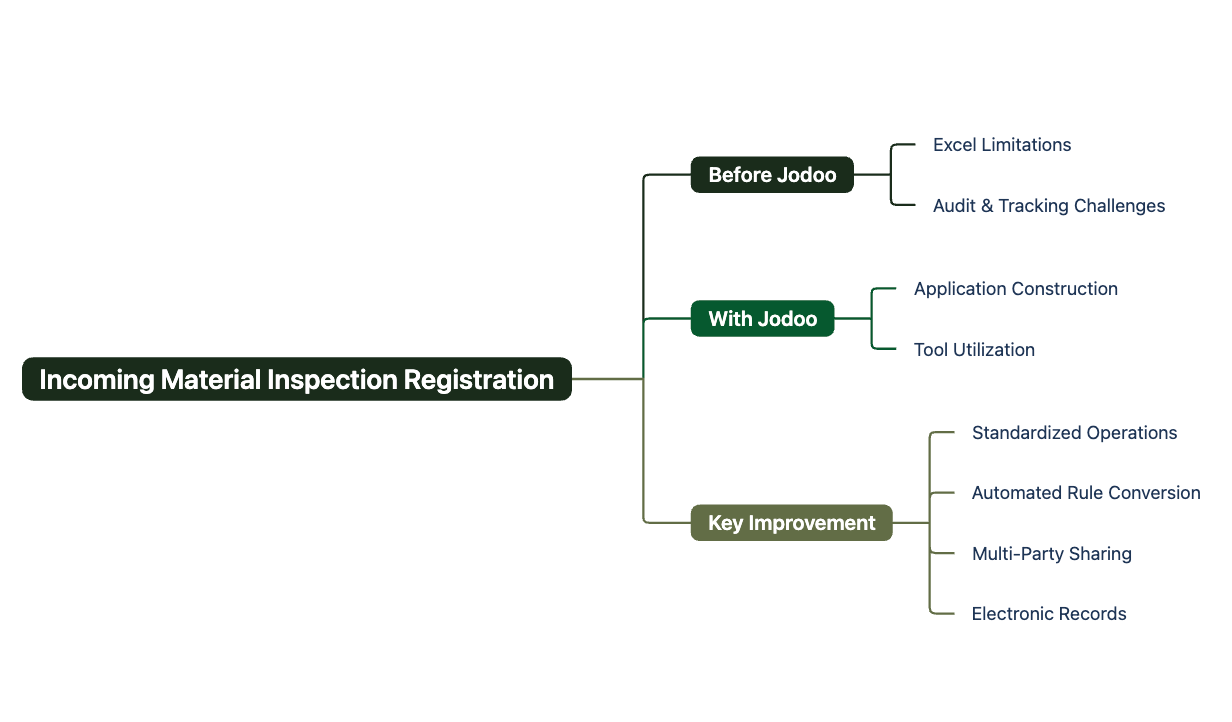

Scenario 1: Incoming Material Inspection Registration

Before Jodoo:

- Audit & Tracking Challenges: Converting and calculating inspection rules was error-prone, making it difficult to meet external audit requirements. Tracking material inspections and real-time supplier queries were nearly impossible. Paper-based records consumed physical space and were cumbersome to search.

With Jodoo:

- Application Construction: Tenneco implemented applications for:

- Factory Outsourced Parts List and Inspection Rules List to register part information and inspection rules.

- Inspection Specification Conversion Rules to define and standardize conversion rules.

- Incoming Material Inspection Registration Form for tracking, problem resolution, and uploading inspection records.

- Tool Utilization:

- Automations within the Incoming Material Inspection Registration Form ensure timely updates of inspection rules.

- The data factory generates daily incoming material inspection reports for each factory.

Key Improvement:

- Standardized Operations: All six factories now uniformly use Jodoo’s cloud-based forms, eliminating inconsistent Excel templates and overcoming computing limitations.

- Automated Rule Conversion: Inspection rules are automatically converted, preventing the chaos and errors previously experienced. Inspectors can now instantly access relevant rules directly within the registration form.

- Multi-Party Sharing: Suppliers can now view inspection rules for parts in real-time, fostering transparency and collaboration.

- Electronic Records: All inspection records are digitized and uploaded to Jodoo Cloud, saving physical space and enabling instant, convenient access and querying.

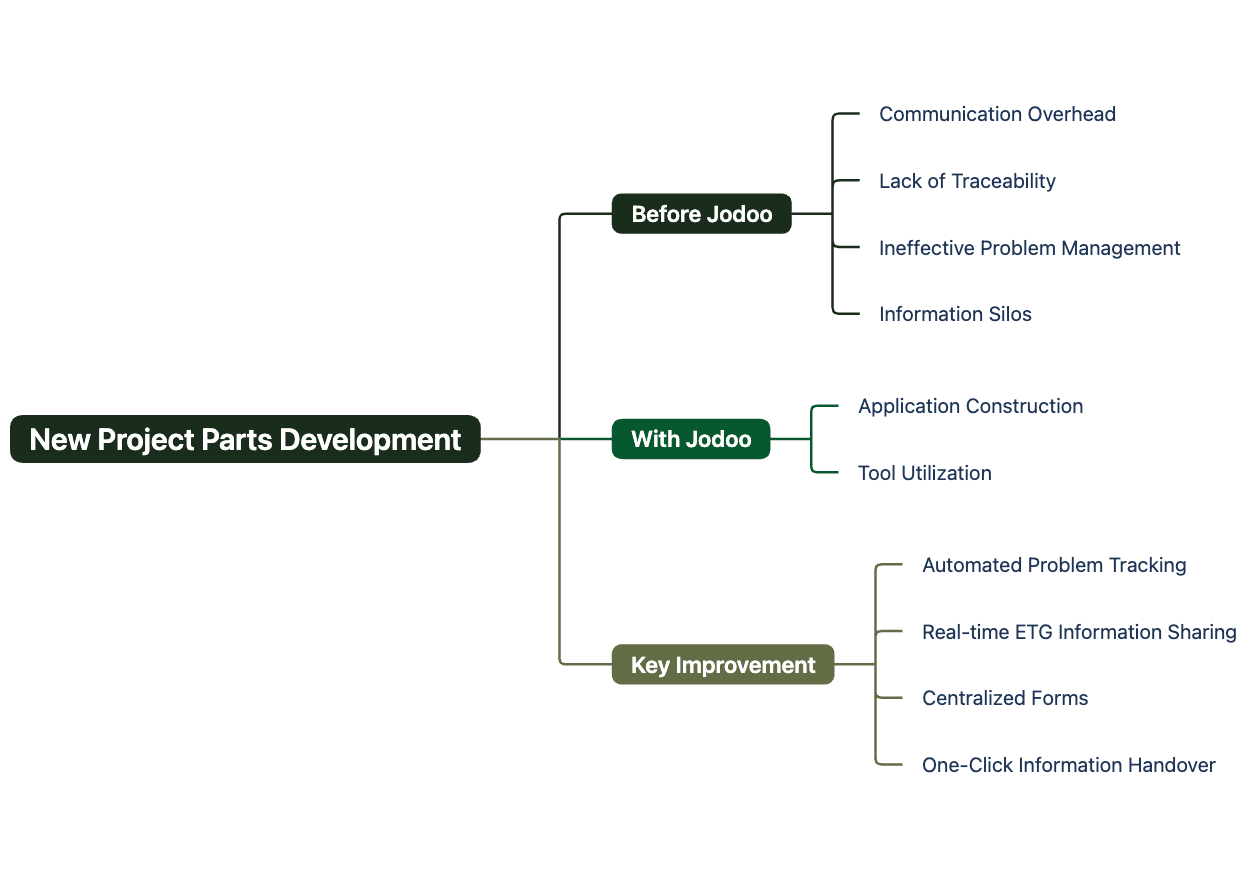

Scenario 2: New Project Parts Development

Before Jodoo:

- Communication Overhead: Suppliers used various Excel versions and formats, significantly increasing communication costs and complexity.

- Lack of Traceability: Communication via email and WhatsApp made it difficult to retain, trace, and view real-time project progress and action plans.

- Ineffective Problem Management: A lack of standardized process tools hindered effective recording and closed-loop management of factory-reported issues to suppliers.

- Information Silos: Offline Excel files were prone to loss during personnel changes, leading to broken chains of problem rectification information.

With Jodoo:

- Application Construction: Tenneco developed applications for:

- New Project Issue Registration to log factory issues, assign tasks to suppliers, and verify status updates.

- JV New Project ETG Development Tracking Table for direct supplier updates and real-time factory monitoring.

- New Project Action Plan for tracking and closing loops on supplier action plans.

- Tool Utilization: The data factory summarizes new project development, including problem rectification, action plan closures, and ETG development progress.

Key Improvement:

- Automated Problem Tracking: Problem task entry and allocation are streamlined, with automated tracking and closure. Factory SQE can register issues via mobile, upload images, and assign tasks, ensuring all parties have real-time visibility.

- Real-time ETG Information Sharing: Suppliers directly update ETG lists and completion times on Jodoo, facilitating real-time review and regular updates between both parties.

- Centralized Forms: All new project development forms are consolidated under one application, simplifying management and access.

- One-Click Information Handover: During personnel changes, unfinished tasks can be seamlessly transferred with a single account switch, preventing information loss.

Conclusion: A Future of Digital Efficiency

Tenneco’s partnership with Jodoo has revolutionized its supplier management processes, transforming a complex, paper-intensive system into a streamlined, digital, and highly efficient operation. By centralizing data, automating workflows, and enhancing communication, Jodoo has empowered Tenneco to achieve greater transparency, accuracy, and responsiveness across its supply chain.

This digital transformation has not only addressed immediate operational challenges but has also laid a robust foundation for future growth and innovation. Tenneco is now better equipped to adapt to evolving market demands, maintain high-quality standards, and foster stronger, more collaborative relationships with its suppliers.

Ready to transform your operations and achieve similar digital excellence? Discover how Jodoo’s no-code platform can empower your business.