$700,000

Annual Financial Savings

97%

Employee Engagement

85.83%

Suggestion Closure Rate

Valmet, a leading global developer and supplier of process technologies, automation, and services for the pulp, paper, and energy industries, has a rich industrial history spanning over 220 years. By 2021, the company employed approximately 17,000 professionals worldwide and achieved net sales of around 4.5 billion euros.

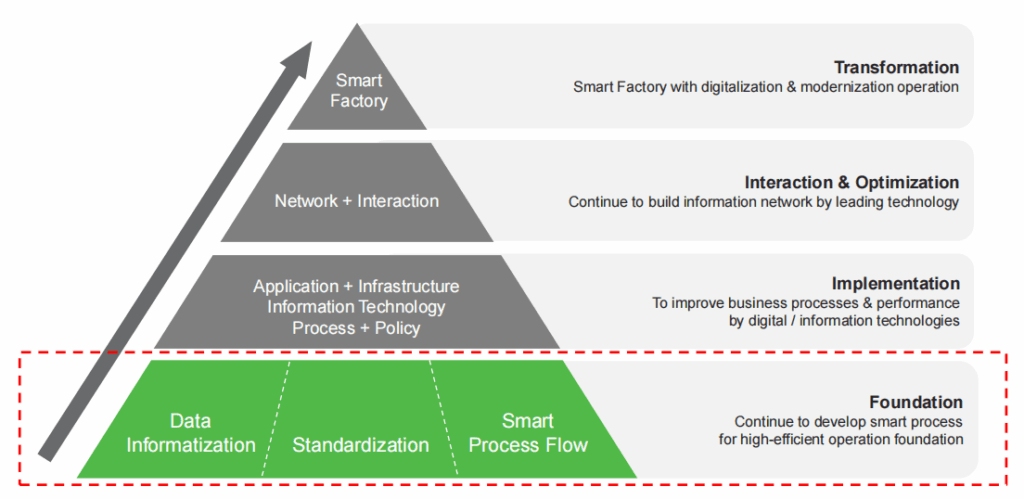

The Challenge: Paper Processes Stalled a Global Leader

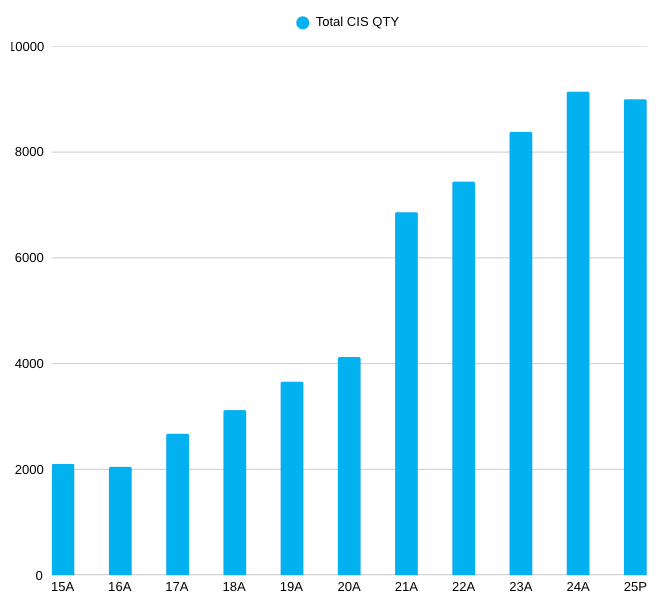

Valmet believes that continuously developing intelligent processes is key to creating a digitalized and visualized smart factory. Valmet has long championed Lean Management with two critical processes: a Continuous Improvement Suggestion System (CISS) and daily production management meetings. However, these processes were hampered by outdated, manual methods.

The CISS, a decade-old program designed to capture employee ideas, was drowning in paperwork. With over 2,000 suggestions submitted annually, the system relied on paper forms, email, and manual data entry into Excel. This manual chaos led to three major problems:

- Slow Processing: Suggestions took too long to approve and implement due to repeated manual transfers and signatures. Suggestions arrived through various channels, including paper forms, email, WhatsApp, and even verbal reports, making centralized collection a nightmare.

- High Error Rate: Managing employee points and rewards manually was not only labor-intensive but also highly error-prone. Coordinators had to input over 2,000 suggestions annually into computers, coordinate with departments, and painstakingly generate statistical reports.

- Low Engagement: Frontline blue-collar workers could not access the company’s global feedback platform, and the cumbersome process led to a decline in employee motivation.

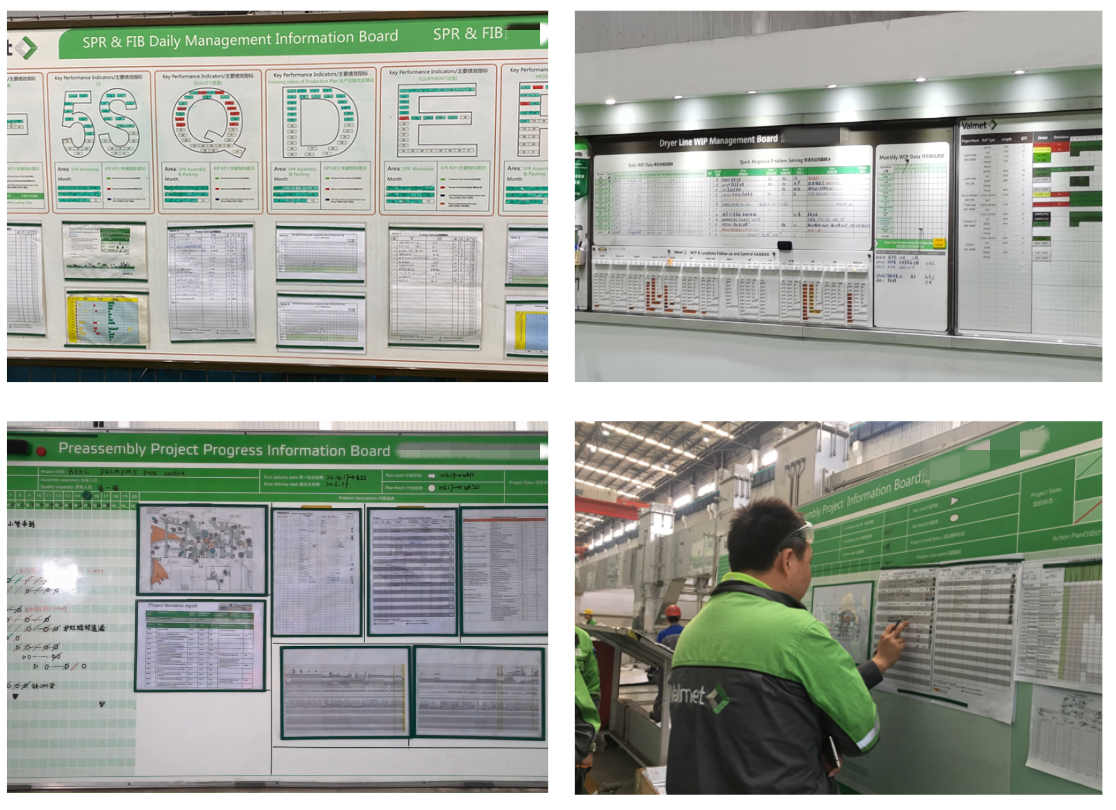

Similarly, daily production management—a cornerstone of lean operations—was inefficient. Teams used physical whiteboards and paper forms to track tasks and problems. This traditional approach lacked real-time data, slowed down problem resolution, and made it impossible to achieve the level of visual management required for a modern smart factory. Valmet recognized that to build a truly digital and visualized factory, they needed a solution that could reach the “last mile” of production and empower non-technical staff.

The Solution: Empowering Business Users with No-Code

Between 2015 and 2018, Valmet attempted to solve these issues with expensive app suites and traditional custom coding. They launched several lean initiatives, including VSM applications, CISS, and CISS+. These projects led to high costs and slow iteration. The company needed a platform that was flexible enough to adapt to its unique, evolving Lean processes without requiring IT resources for every change.

In 2019, Valmet discovered Jodoo. The platform offered two key advantages:

- Speed and Flexibility: The Lean manager could participate directly in building and modifying apps. This eliminated communication delays and allowed processes to iterate quickly as needs evolved.

- Cost-Effectiveness and Access: Jodoo delivered rapid solutions without expensive custom code. Crucially, its enterprise controls and mobile access allowed Valmet to finally include all blue-collar workers in the digital process.

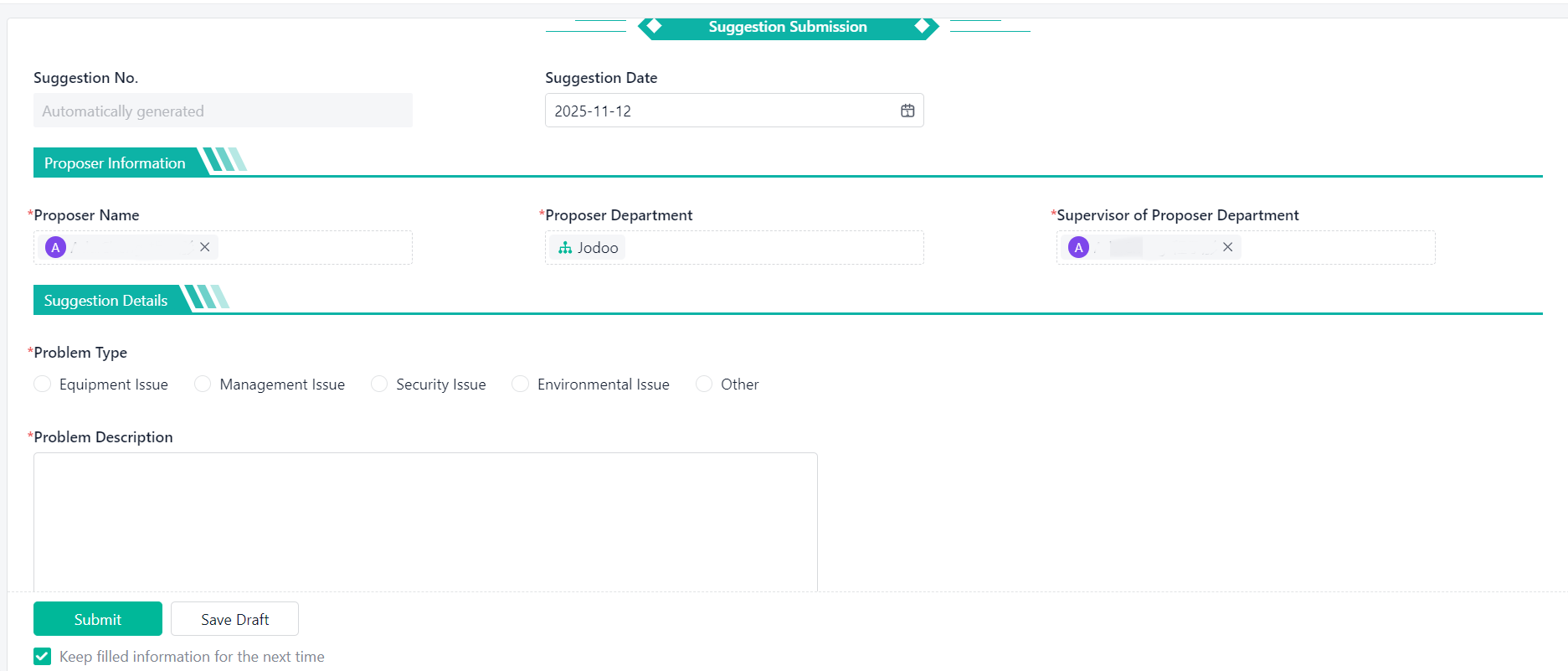

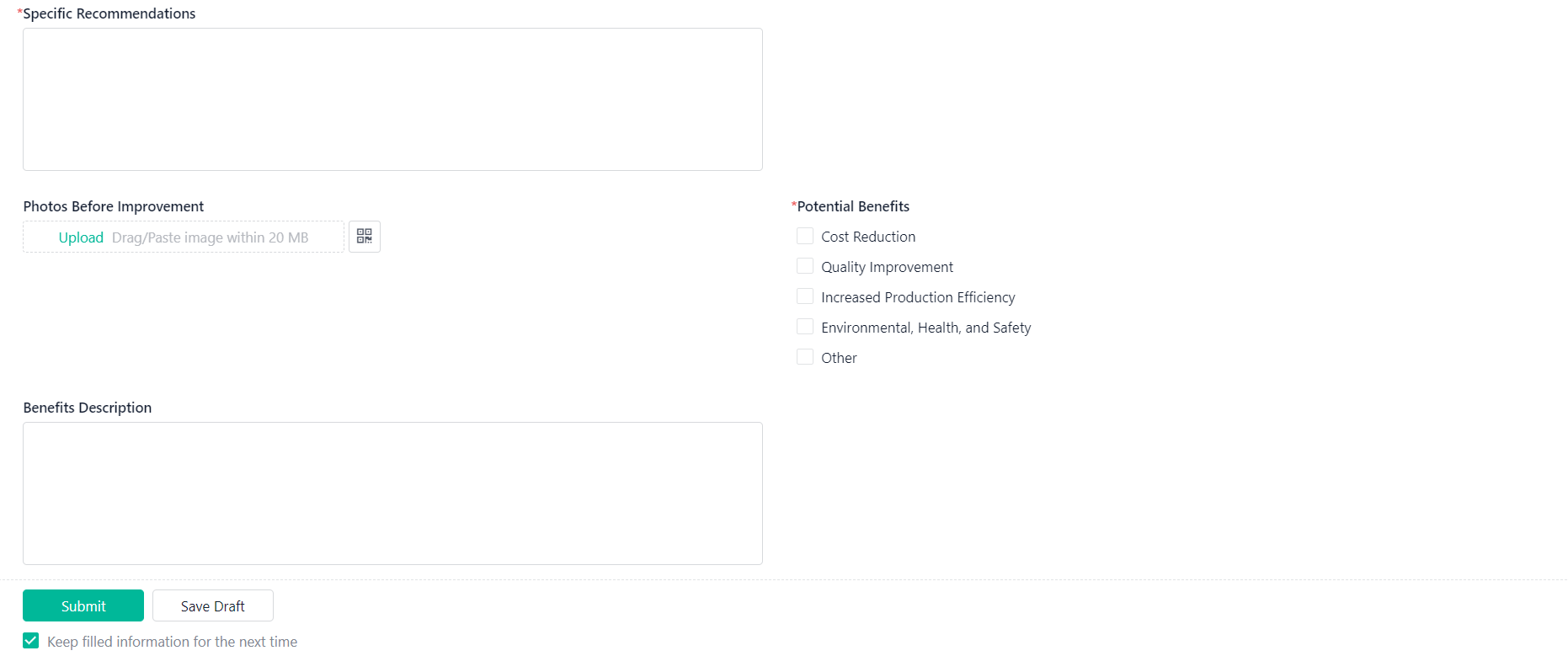

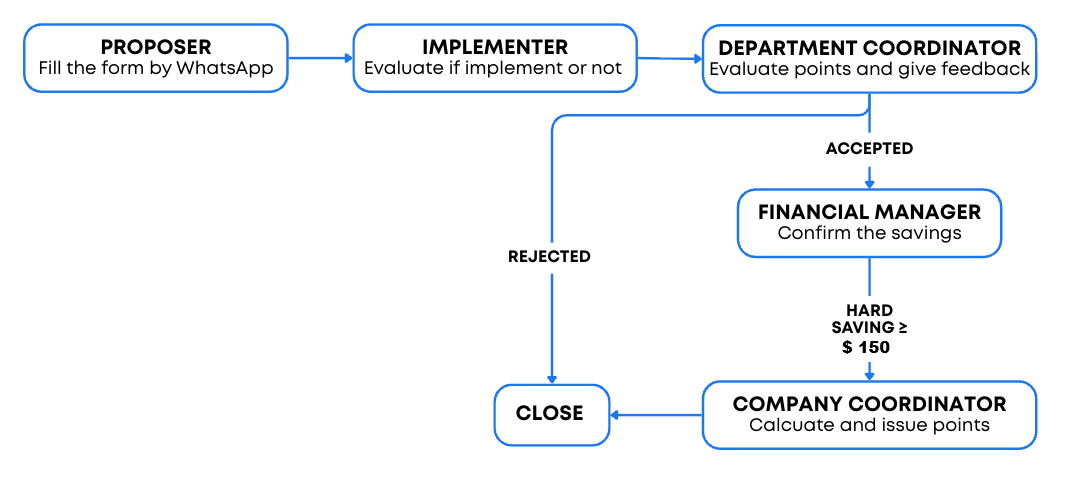

The Digital CISS Platform: A Closed-Loop System

Valmet decided to build a replacement for the CISS system first. They automated the entire workflow, eliminated manual data entry, and accelerated resolution. This effort resulted in five key achievements:

Valmet built simple, mobile-friendly forms for idea submission with attachments and multi-select dimensions.

Employees now submit ideas through a standardized form accessible via their WhatsApp, ensuring a unified submission channel.

Automated Routing and Approval

The system automatically assigns an ID and routes the suggestion to the department coordinator for initial evaluation. If valid, the idea moves to the designated implementer. The Head of Department (HoD) screens the idea, records potential savings (Cost Saving, Cost Avoidance, No Saving), and updates estimates. Rejections require a reason and automatically notify the submitter.

Suggestions are now automatically routed to the department coordinator for initial evaluation and scoring. If valid, the idea is passed to the designated implementer.

Closed-Loop Management

The assigned executor receives automated notifications and maintains the status: Submitted for approval → Received → In Progress → Done → Rejected. Once the improvement is complete, the workflow routes back to the coordinator for final audit and closure.

The process is designed as a closed loop with role-based delegation, ensuring accountability.

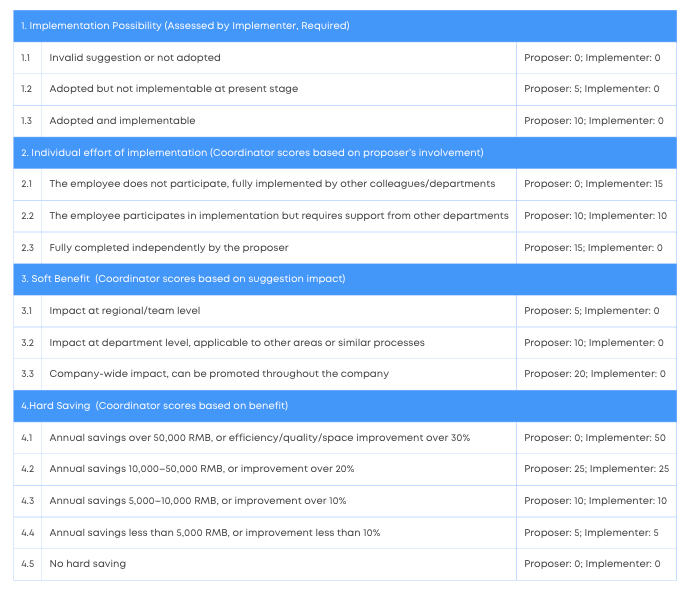

Real-Time Rewards and Tracking

When an idea is marked Done, Finance validates and confirms the savings. The system instantly issues points to the suggester.

Employees can instantly view their points balance on a data dashboard and use a separate workflow to redeem them for physical rewards, eliminating error-prone manual points management. The real-time reporting feature also provides management with instant data analysis, replacing the need for manually created statistical reports.

Accessibility

By integrating with WhatsApp, the platform is fully accessible to all frontline blue-collar workers.

The Smart Meeting App

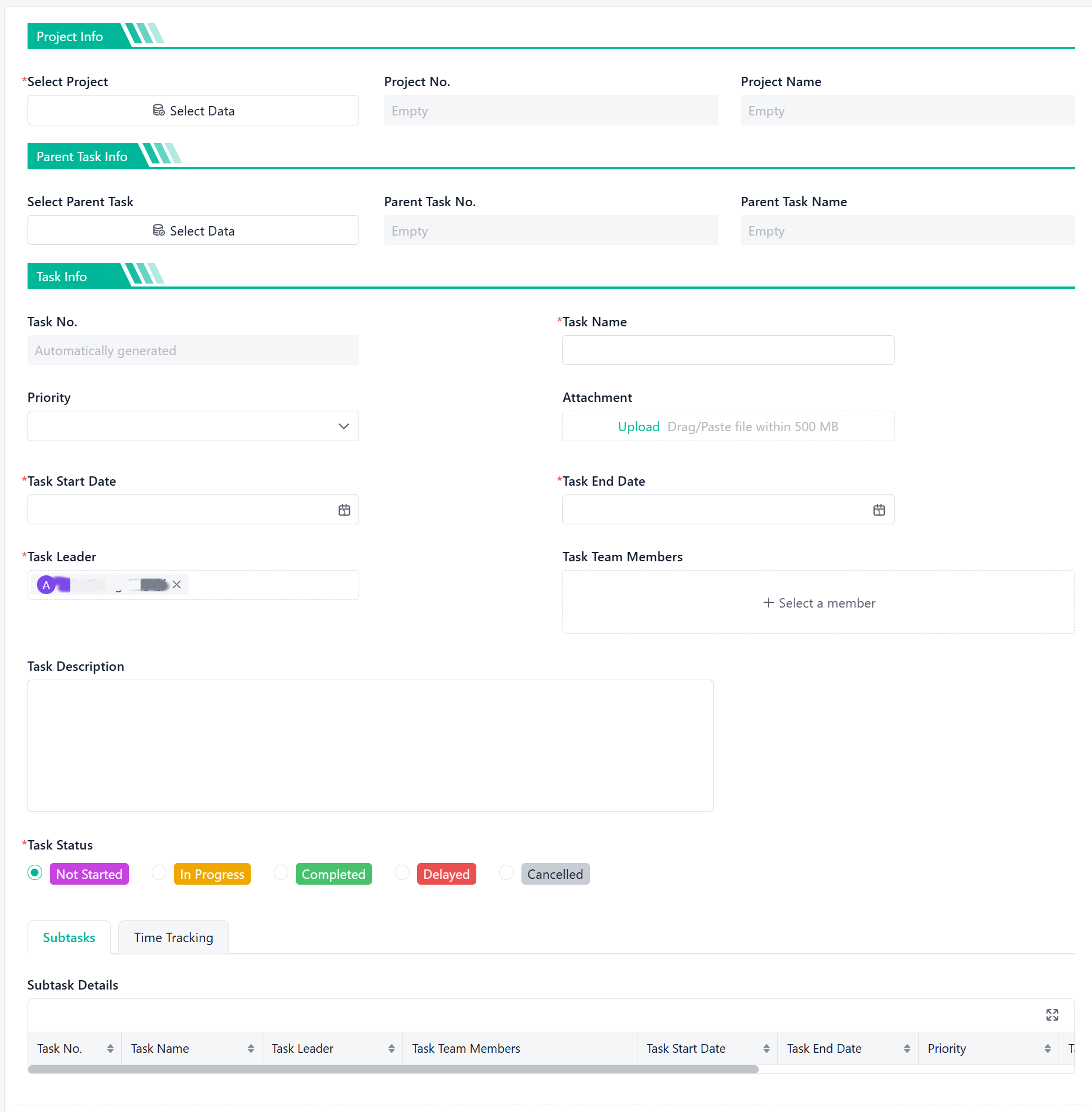

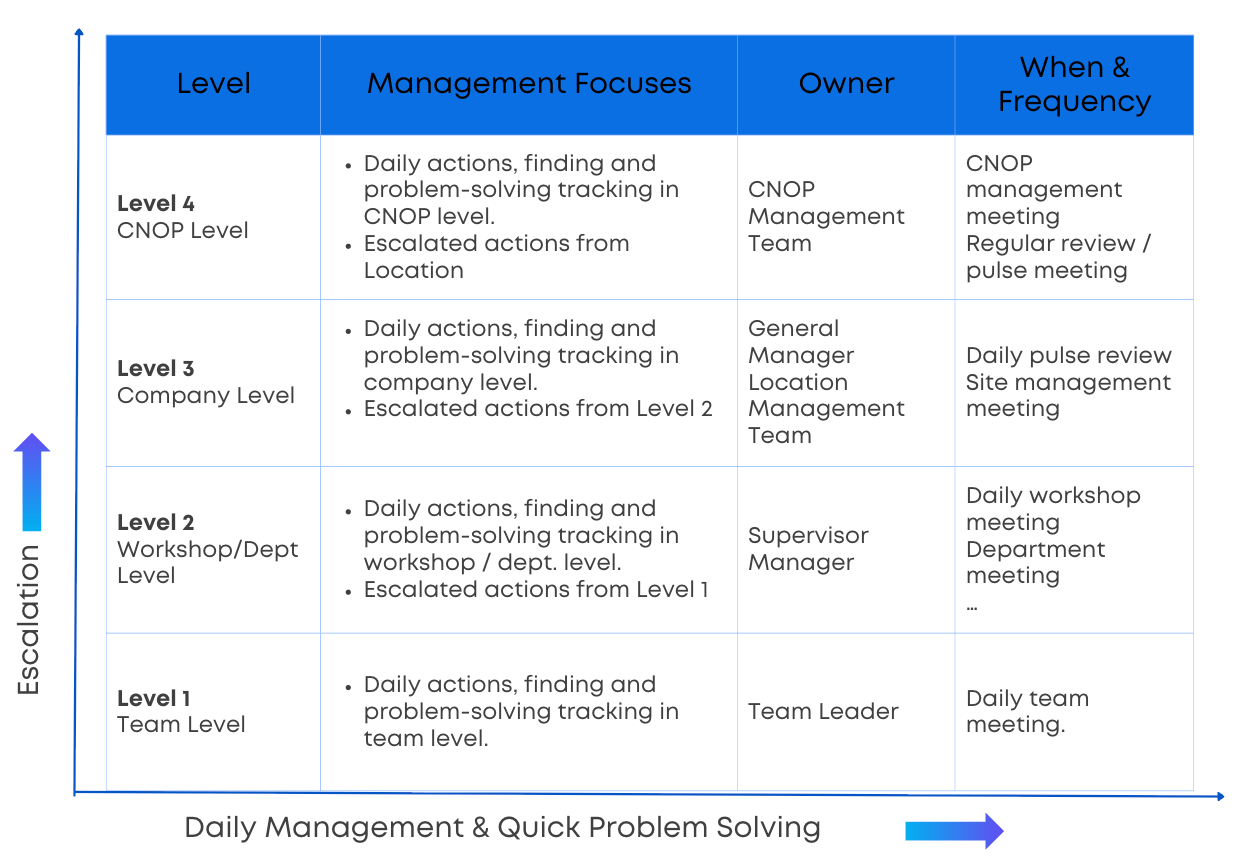

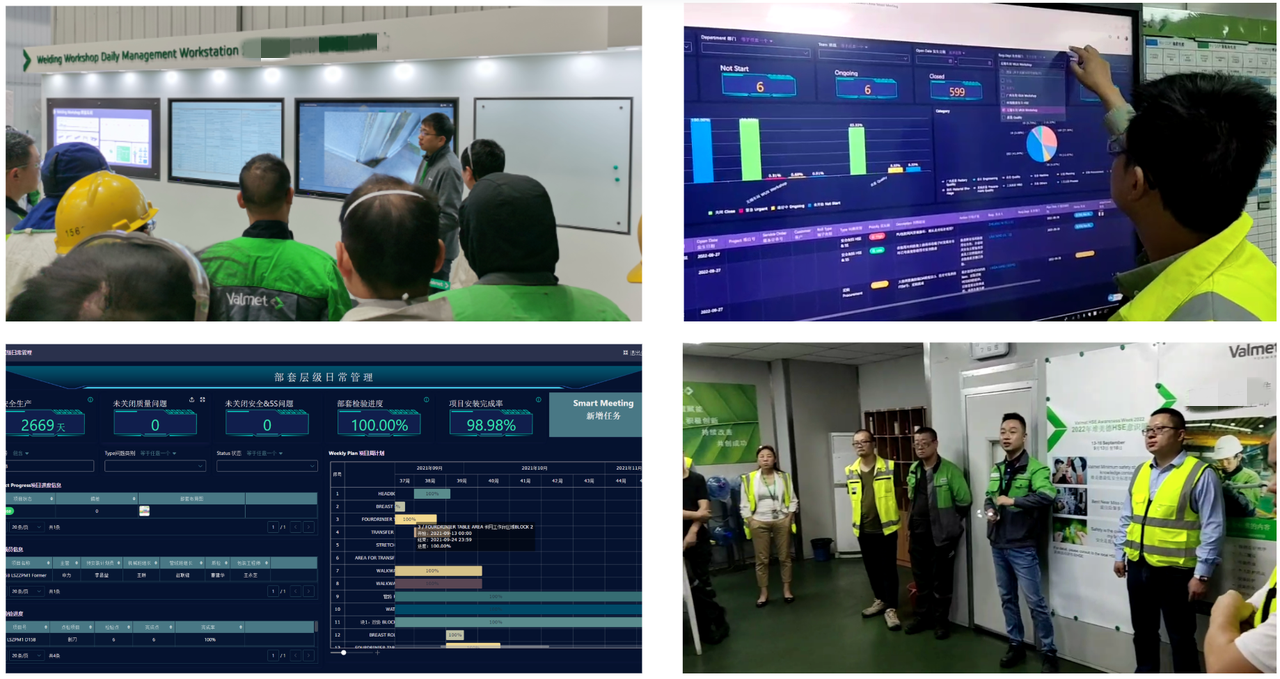

Next, Valmet’s Lean department standardized the daily management process across all levels—from frontline teams to company leadership—to address the inefficiencies of traditional whiteboards and paper forms. They used Jodoo to build the Smart Meeting app, which acts as a digital control center for daily operations:

Process Standardization

The app enforces a standardized daily management process, including clear management hierarchies (Frontline Team → Department → Company Level) and defined problem categories (Safety & 5S, Quality, Equipment, Material, Design, etc.).

Digital Task Management

It uses modular, standardized forms with attachment capabilities to customize the task release and feedback submission process. This enables real-time transfer of information and tasks, ensuring clarity and reducing miscommunication and redundant steps.

Real-Time Visual Management

Customized, real-time reports and dashboards replace old physical whiteboards with large digital screens. This provides clear, visual data on production status and problem-solving progress, eliminating the need for manual board updates and ensuring that information, tasks, and feedback are transferred instantly for rapid problem resolution.

Cross-Regional Support

The system was designed to support cross-regional task submission, with forms that combine universal fields with local, customized fields, automatically displaying the correct data based on the submitting company.

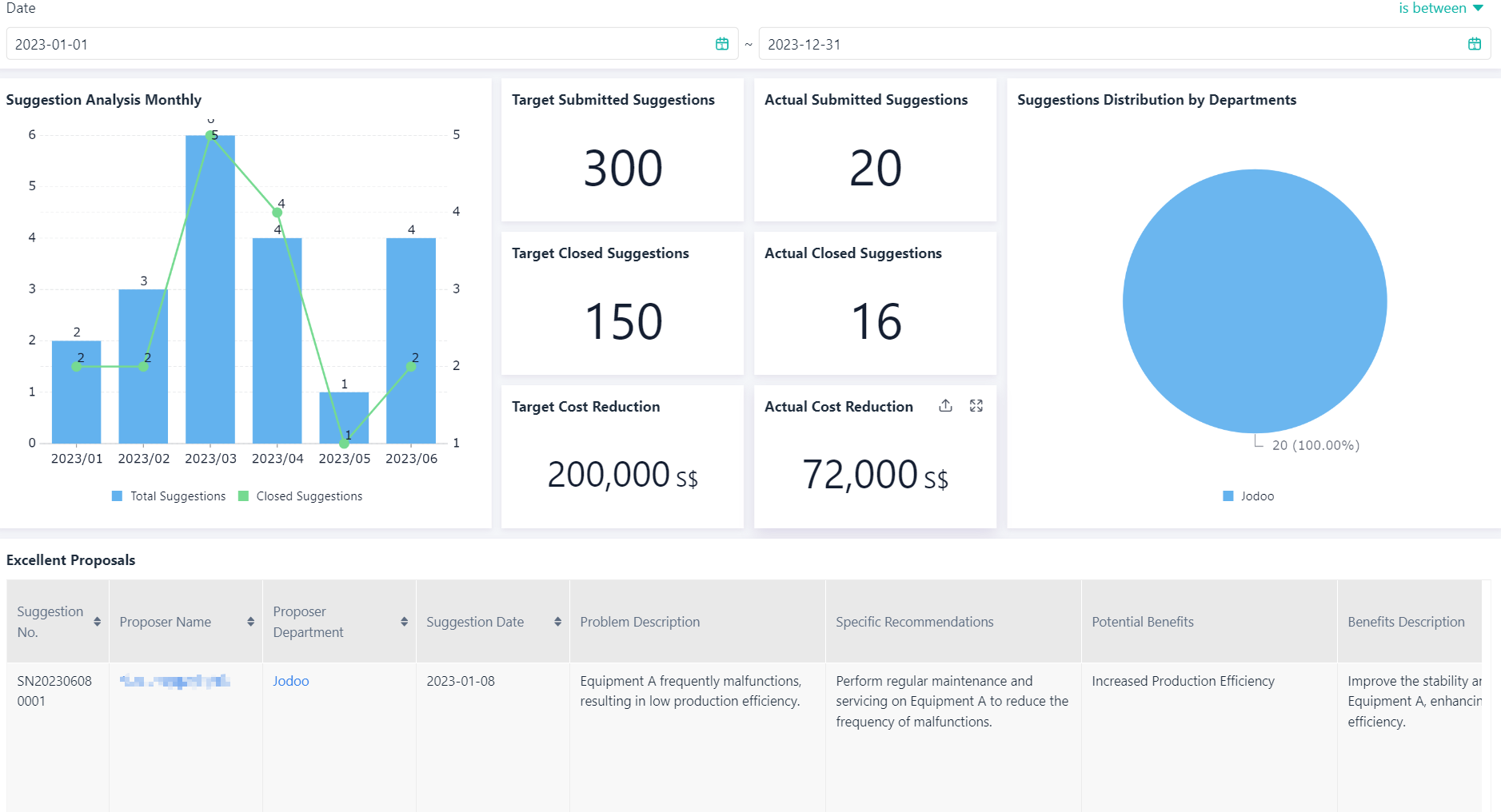

The Results: A Rapid Return on Investment and 97% Employee Engagement

The implementation of Jodoo delivered immediate and quantifiable results, demonstrating a rapid return on investment (ROI).

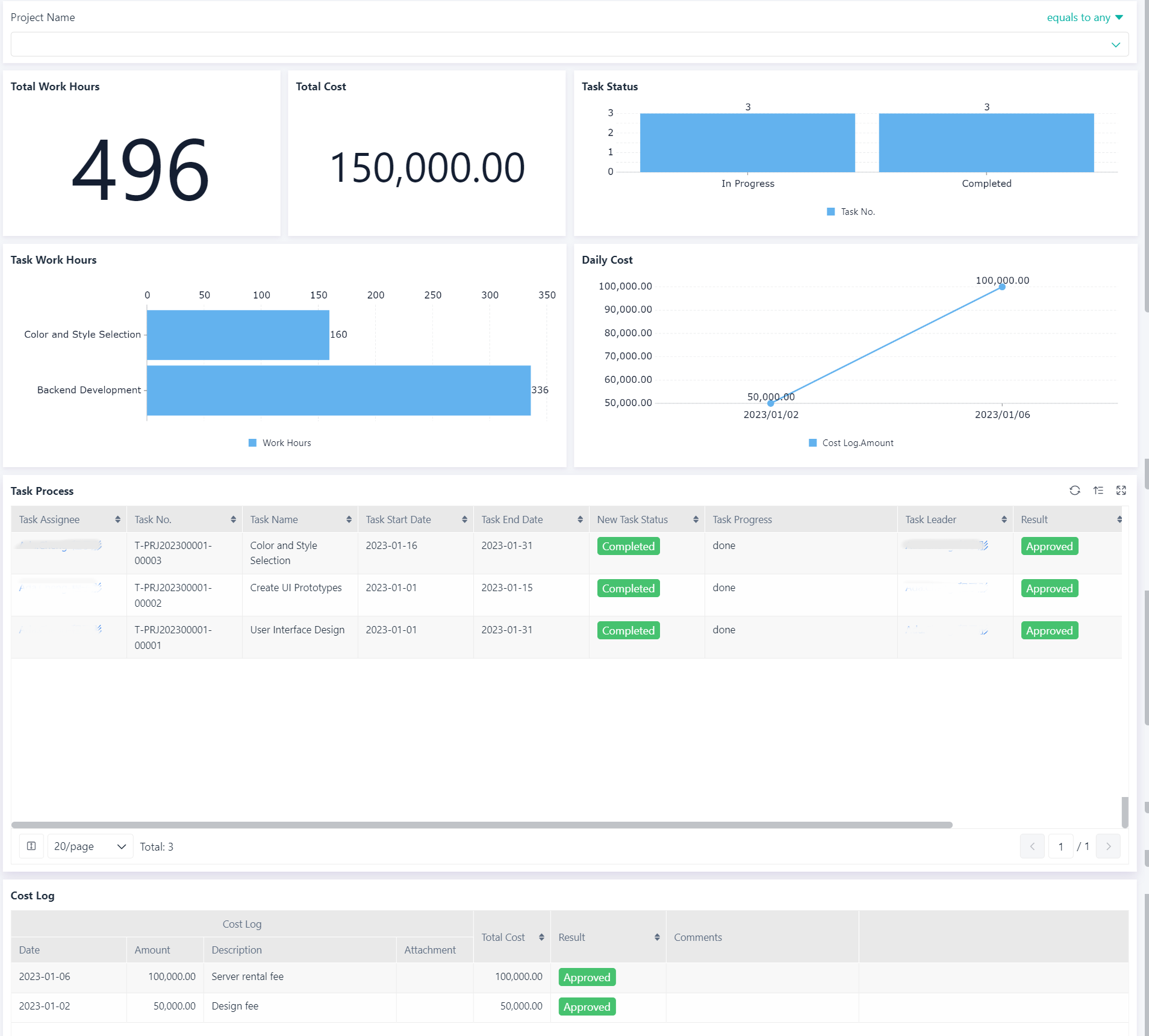

| Key Performance Indicator | Before Jodoo | After Jodoo |

|---|---|---|

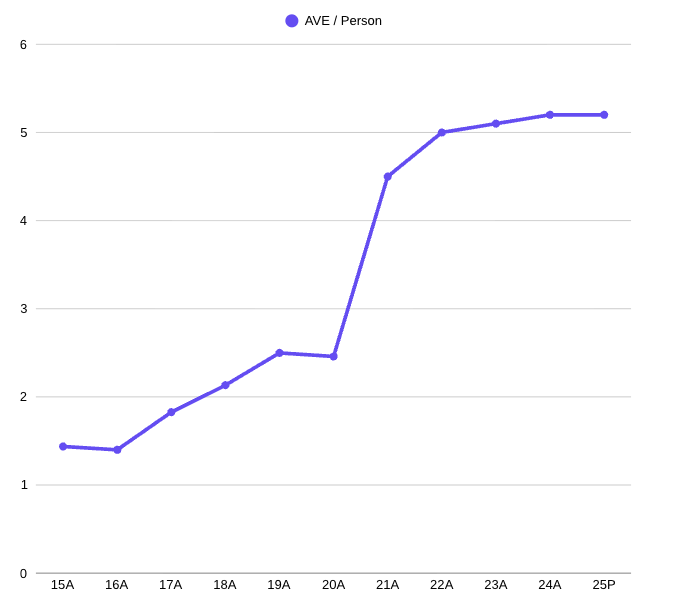

| Annual Financial Savings | $1,000 | $700,000 |

| Employee Engagement | 36% | 97% |

| Suggestion Closure Rate | 13.3% | 85.83% closure rate on 7,162 suggestions submitted in two years. |

| Daily Management Coverage | 64% | 100% |

| Suggestions Volume | Around 2,000 | Significantly increased.  |

The financial impact is particularly compelling: while the factory issues an average of $ 8,500 in annual rewards, the suggestions generated have delivered a financial saving of over $700,000 annually.

Future Outlook: Valmet Controls Its Digital Destiny

Valmet’s success with Jodoo has fundamentally changed the perception of digitalization within the company. What was once viewed as a “high-end” or unattainable vision is now a practical reality that penetrates every process and every person’s daily work.

“Jodoo is an excellent tool supplement that solved the ‘last mile’ needs of frontline production. It has shown us that digitalization is not just for IT, but can truly help us improve work efficiency across the board.”

Having built over 40 apps, Valmet is continuing to expand its use of Jodoo into areas like facility and equipment management and warehouse management. The success of the Jiading factory is now being replicated across other Valmet facilities, with a new company-wide requirement for all employees to submit an average of four effectively executed suggestions per year.

By leveraging no-code development, Valmet has not only optimized its operations but has also secured its ability to quickly adapt and innovate, ensuring its digital destiny is controlled by the business users closest to the action.

Ready to empower your business users and achieve rapid ROI?